Welded wire mesh, a versatile and essential construction material, often prompts inquiries about its pricing—specifically, the cost per square foot. Understanding these costs involves more than a simple price tag; it encompasses material quality, manufacturing processes, market demand, and supplier integrity. Being well-informed can ensure that consumers make decisions aligning with their project needs and budget constraints.

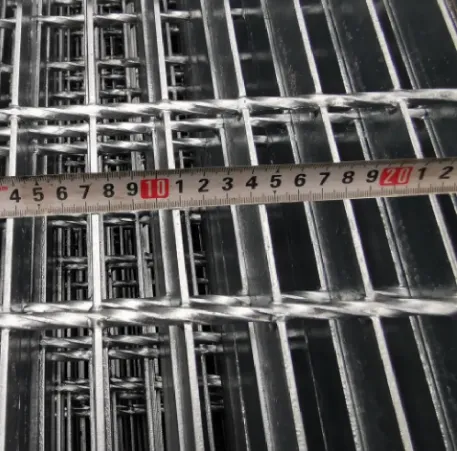

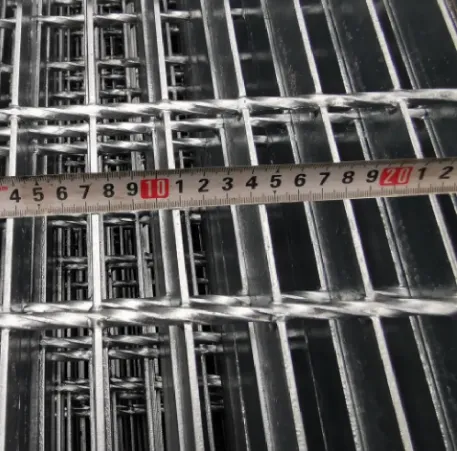

Starting with the basic composition, welded wire mesh is made by welding individual cross wires at set intervals, generally manufactured from steel. The width of application ranges from concrete reinforcement, fencing, and security mesh, to animal pens, offering a sturdy yet flexible solution. Quality here is key; industry professionals emphasize that while cheaper meshes exist, opting for a higher-grade steel ensures durability and performance, particularly in demanding environments.

Currently,

the price of welded wire mesh per square foot is influenced by various factors. Raw material costs represent a significant portion. Steel prices have been volatile over the years, swayed by international demand, transportation costs, and geopolitical factors. For a contractor or homeowner, these fluctuations are crucial as they can impact overall project budgets markedly.

Another component affecting price is the manufacturing process. Automated, precision welding typically results in a more uniform and reliable product, albeit at a slightly elevated cost. However, the benefit far outweighs the initial outlay as the longevity and low maintenance requirements of superior mesh prevent future expenses.

welded wire mesh price per square foot

From an expert's perspective, sourcing is an essential aspect of assessing welded wire mesh prices. Reliable suppliers with transparent pricing models and industry certifications tend to offer the best value. Such suppliers not only provide detailed cost breakdowns but are also more likely to recommend mesh that suits specific structural requirements, reducing wastage and ensuring optimal performance.

In addressing the credibility and reliability of information, one can turn to industry reports, consultation with certified engineers, and customer reviews. For example, experienced users endorse sticking with recognized brands, even if they appear pricier. Their investment in quality control, adherence to safety standards, and post-purchase support often justifies the additional cost per square foot because these factors contribute to the mesh's expediency during complex projects.

Trustworthiness in price consideration also involves understanding additional costs, such as for shipping, installation, and any required surface treatments like galvanization or powder coating, which protect the mesh from corrosion. Most suppliers offer detailed quotes that outline these elements, allowing for precise budgeting.

Ultimately, the price per square foot of welded wire mesh isn't solely about the initial cost; it is about the long-term value it delivers. By wisely choosing high-quality materials from reputable suppliers, and by integrating expert recommendations, consumers not only protect their investments but also enhance the safety and stability of their constructions. Hence, an informed approach emphasizing quality and reliability, rather than just cost savings, benefits any project where welded wire mesh is a cornerstone.