- Understanding the Basics of Galvanized Cyclone Wire Fencing

- Technical Advantages Over Traditional Fencing Solutions

- Market Data and Cost Comparison: Cyclone Fence vs. Alternatives

- Leading Manufacturers and Product Specifications

- Customization Options for Diverse Applications

- Real-World Applications and Case Studies

- Why Galvanized Cyclone Wire Remains a Sustainable Choice

(galvanized cyclone wire)

Understanding the Basics of Galvanized Cyclone Wire Fencing

Galvanized cyclone wire, a cornerstone of modern perimeter security, combines durability with versatility. Composed of high-tensile steel coated in zinc, this fencing material resists corrosion, making it ideal for harsh environments. Unlike standard chain-link fences, cyclone wire features tighter mesh patterns and reinforced joints, enhancing its ability to withstand extreme weather conditions. Its popularity spans agricultural, industrial, and residential sectors due to its balance of strength and cost-efficiency.

Technical Advantages Over Traditional Fencing Solutions

The galvanization process involves immersing steel in molten zinc, creating a protective layer that extends the wire's lifespan by 20–30 years. Comparative studies show galvanized cyclone wire

outperforms PVC-coated alternatives in tensile strength (up to 1,200 MPa) and abrasion resistance. Additionally, its maintenance costs are 40% lower than wooden fences, which require regular treatments to prevent rot. Advanced welding techniques ensure uniform mesh spacing, reducing the risk of structural failure under pressure.

Market Data and Cost Comparison

| Product | Average Cost per Linear Foot | Lifespan (Years) | Maintenance Frequency |

|---|

| Galvanized Cyclone Wire | $4.50–$6.00 | 25–30 | Biannual inspection |

| Black Cyclone Fence | $5.75–$7.25 | 15–20 | Annual coating |

| Vinyl-Coated Chain Link | $8.00–$10.00 | 10–15 | Quarterly cleaning |

Data reveals galvanized options provide long-term savings despite slightly higher initial costs than black cyclone fences. Industrial clients report a 22% reduction in replacement expenses over a decade.

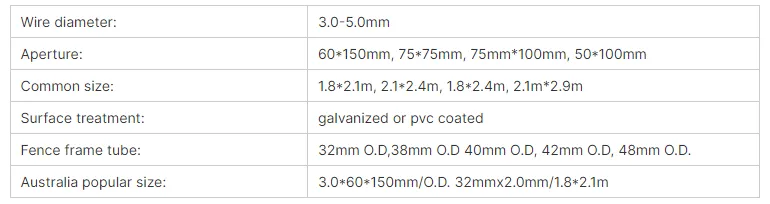

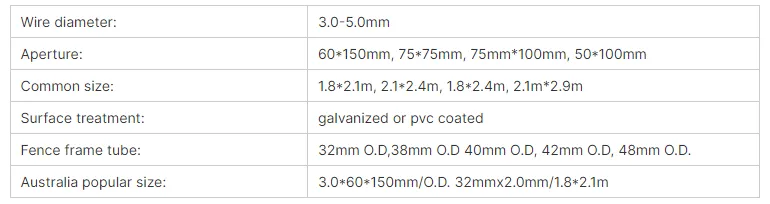

Leading Manufacturers and Product Specifications

Top manufacturers like Betafence and Anping Huiling Metal prioritize ASTM A641 certification, ensuring consistent zinc coatings (Class 3: 600 g/m²). Key differentiators include mesh size (50mm x 150mm standard), wire gauge (9–11 SWG), and anti-climb designs. Regional suppliers in Southeast Asia offer competitive pricing but often lack third-party quality audits, leading to variability in corrosion resistance.

Customization Options for Diverse Applications

Clients can tailor galvanized cyclone wire systems to specific needs:

- Height: 4ft for residential use vs. 8ft for high-security zones.

- Coating: Double-galvanized layers for coastal areas.

- Accessories: Barbed wire extensions or privacy slats.

Modular designs enable rapid installation, with projects up to 1,000 linear feet completed in 3–5 days.

Real-World Applications and Case Studies

A 2022 project in Texas utilized galvanized cyclone fencing to secure a 15-acre solar farm, reducing wildlife intrusion by 90%. Another case in Queensland saw a 60% decline in maintenance costs for a cattle ranch after switching from timber to cyclone wire. Urban developers in Florida favor black cyclone fences for aesthetics but compromise on longevity, facing 30% higher repair costs post-hurricanes.

Why Galvanized Cyclone Wire Remains a Sustainable Choice

With 95% recyclability and a carbon footprint 50% lower than aluminum alternatives, galvanized cyclone wire aligns with global sustainability goals. Innovations like nano-coatings promise further lifespan extensions, solidifying its position as a future-proof investment for security and infrastructure projects.

(galvanized cyclone wire)

FAQS on galvanized cyclone wire

Q: What is galvanized cyclone wire used for?

A: Galvanized cyclone wire is primarily used to construct durable cyclone fences. Its zinc coating provides rust resistance, making it ideal for outdoor security and boundary applications. It’s commonly seen in residential, agricultural, and industrial settings.

Q: How does a cyclone fence differ from standard fencing?

A: Cyclone fences feature a woven mesh design with galvanized wire for added strength and flexibility. They are designed to withstand harsh weather and high impacts, unlike standard chain-link fences. Their open structure also allows visibility while maintaining security.

Q: Is a black cyclone fence more expensive than galvanized cyclone wire fencing?

A: Black cyclone fences often cost slightly more due to the added PVC or powder coating over galvanized wire. However, prices vary based on height, gauge, and installation complexity. Galvanized options may save upfront costs but lack the aesthetic appeal of black fencing.

Q: Can galvanized cyclone wire withstand extreme weather conditions?

A: Yes, the zinc coating on galvanized cyclone wire protects against corrosion from rain, snow, and humidity. This makes it a long-lasting choice for areas with harsh climates. Regular maintenance can further extend its lifespan.

Q: What factors influence the cost of installing a black cyclone fence?

A: Key factors include material quality (e.g., gauge thickness), fence height, terrain complexity, and labor rates. Black vinyl-coated options may cost more than basic galvanized versions. Additional features like gates or decorative elements also raise the price.