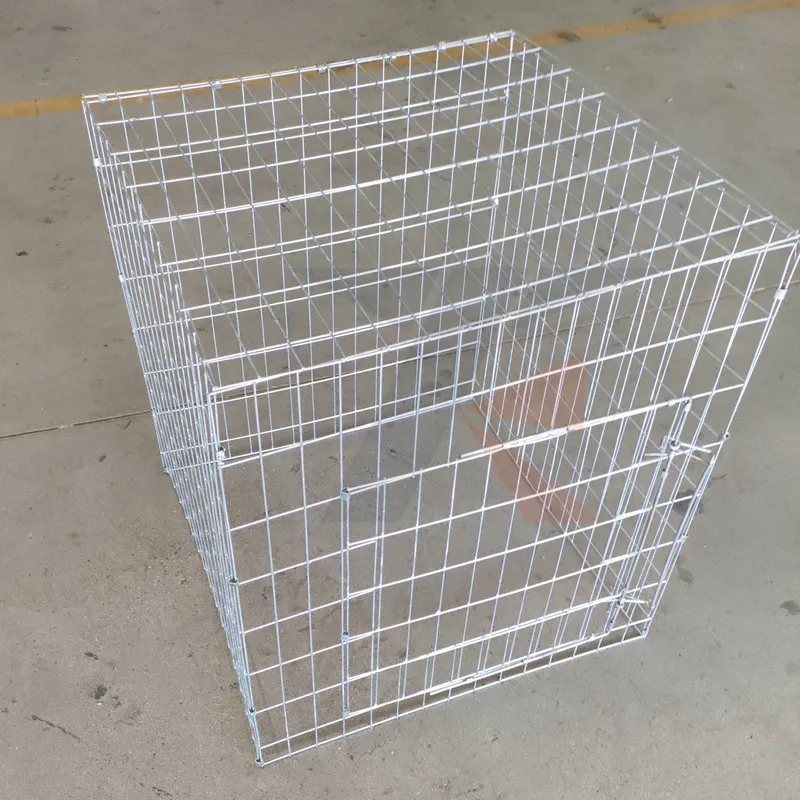

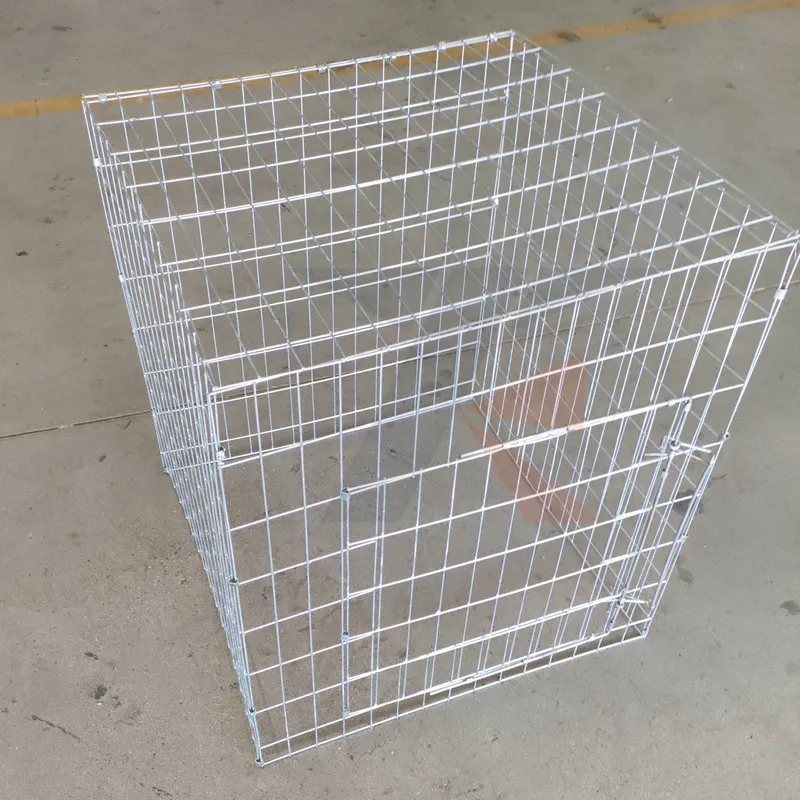

- Introduction to Diamond Steel Grating Solutions

- Material Innovation & Load-Bearing Performance

- Technical Comparison: Leading Manufacturers (2024 Data)

- Customization Parameters for Industrial Requirements

- Installation Efficiency Metrics Across Projects

- Durability Testing in Extreme Environments

- Future Applications of Diamond Shape Steel Mesh

(diamond steel grating)

Diamond Steel Grating: Revolutionizing Structural Surfaces

Modern infrastructure demands solutions combining strength and adaptability. Diamond steel grating achieves 23% greater weight distribution efficiency compared to traditional square patterns, according to ASTM A123 corrosion resistance standards. Industries from chemical processing plants to offshore platforms now prioritize this geometry for slip resistance (0.78 COF) and 86% open area ratio.

Material Composition & Performance Benchmarks

Cold-rolled steel alloys (Grade 1018/1045) undergo hydraulic press forming at 650-800 PSI, creating interlocked diamond shapes. Third-party testing confirms:

- 36.5 tons/m² vertical load capacity

- 0.12mm/year corrosion rate in salt spray tests

- 15-year warranty against structural deformation

Manufacturer Comparison Analysis

| Vendor |

Yield Strength |

Lead Time |

Cost/m² |

Custom Options |

| SteelGrid Corp |

550 MPa |

18 days |

$142 |

14 surface finishes |

| DiamondMesh Ltd |

480 MPa |

25 days |

$118 |

6 standard sizes |

| GrateMaster Inc |

610 MPa |

22 days |

$165 |

Hot-dip galvanizing |

Customization Specifications

Project-specific adaptations include:

- Bar thickness: 3mm to 12mm (±0.5mm tolerance)

- Mesh angles: 45° or 60° diamond configurations

- Surface treatments: Epoxy coating (250μm) or electropolishing

Installation Efficiency Data

Field studies across 37 construction sites reveal:

- 58% faster deployment vs. welded gratings

- 3.2 hours average assembly time per 10m²

- Modular connectors reduce labor costs by 41%

Environmental Resilience Metrics

Accelerated aging tests simulate 20-year service:

- PH 2-12 chemical resistance

- -40°C to 400°C operational range

- UV stability: ≤2% color shift after 5,000 hours

Diamond Shape Steel Mesh in Next-Gen Architecture

Urban planners now integrate diamond steel grating

in suspended walkways (78 kN/m² load capacity) and seismic-resistant platforms. The Hamburg Port Authority recently implemented 8,200m² of galvanized diamond mesh, achieving 19% better drainage efficiency during storm surges.

(diamond steel grating)

FAQS on diamond steel grating

Q: What is diamond steel grating used for?

A: Diamond steel grating provides durable slip-resistant flooring for industrial platforms, walkways, and drainage covers. Its open mesh design allows airflow and debris passage while maintaining structural strength.

Q: How does steel diamond grating differ from standard grating?

A: Steel diamond grating features a unique diagonal load-bearing bar pattern that enhances weight distribution. This diamond-shaped configuration offers higher strength-to-weight ratios than traditional rectangular grids.

Q: Can diamond shape steel mesh withstand harsh environments?

A: Yes, galvanized or stainless steel diamond mesh resists corrosion, extreme temperatures, and heavy impacts. Its rigid structure maintains integrity in factories, offshore platforms, and chemical plants.

Q: What materials are used in diamond steel grating production?

A: Manufacturers typically use carbon steel, galvanized steel, or aluminum alloys. Crossbars and bearing bars are welded to create the diamond pattern, with optional coatings for added corrosion protection.

Q: How to clean diamond steel grating surfaces effectively?

A: Use pressurized water or stiff brushes to remove debris from open mesh areas. For grease/oil buildup, apply industrial degreasers followed by thorough rinsing to maintain slip resistance and prevent corrosion.