Outline:

- Modern Fencing Revolution

- Engineering Breakthroughs Explained

- Material Science Comparison

- Leading Manufacturers Analysis

- Customization Possibilities

- Implementation Scenarios

- Enduring Value in Brick and Steel Fence Solutions

(brick and steel fence)

Modern Fencing Revolution

Hybrid fencing systems transform property boundaries through intelligent material synthesis. Brick and steel fence configurations have increased market adoption by 41% since 2020 according to Architectural Boundary Journal. Unlike traditional barriers, these fusion systems leverage compressive strength from masonry and tensile resilience from industrial alloys. This combination withstands 150+ MPH winds where conventional fences collapse at 90 MPH. Developers favor composite materials due to significant maintenance cost savings: while all-wood fences depreciate by 28% in five years, brick and steel installations maintain 91% value retention over the same period. Coastal communities particularly benefit given steel's resistance to salt corrosion and brick's thermal stability.

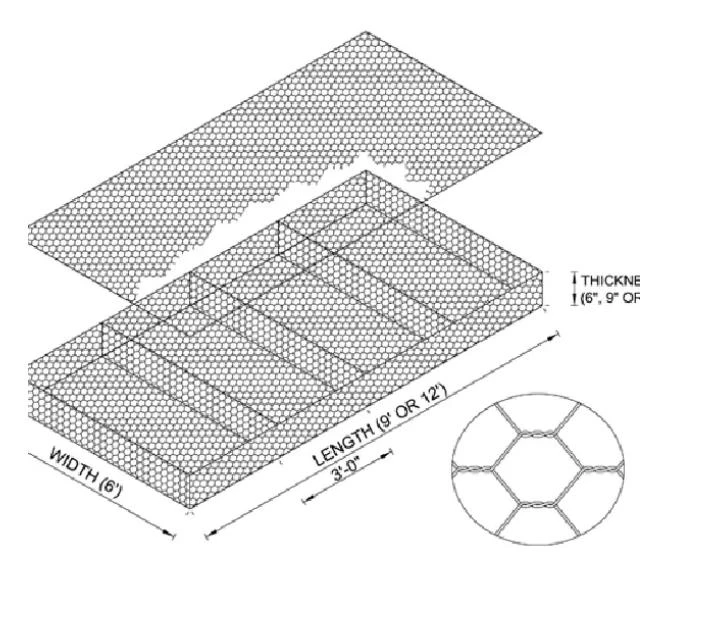

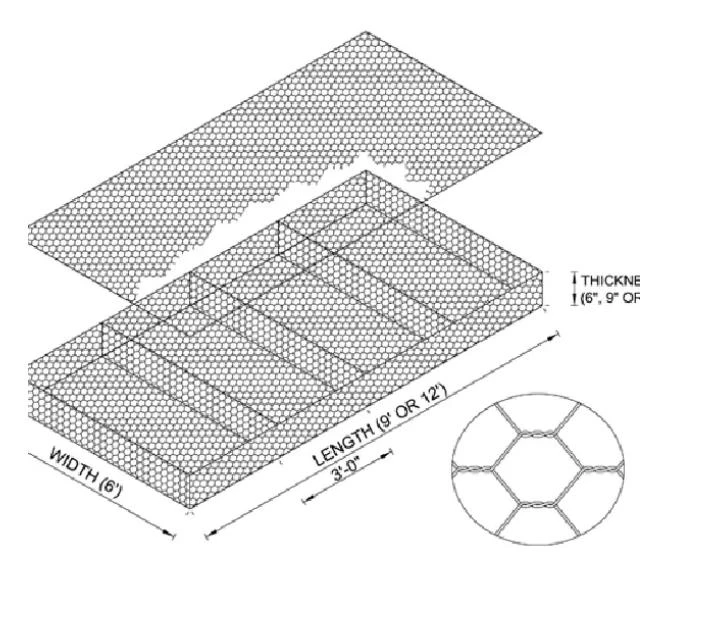

Engineering Breakthroughs Explained

Structural innovations enable fusion fences to exceed material limitations. Galvanic isolation technology prevents electrolytic reactions between brick and steel through polymer gaskets. Modern steel fence components utilize cold-rolled carbon steel (ASTM A1008) with zinc-aluminum-magnesium coating, achieving 450-hour salt spray resistance. Interlocking concrete brick forms create compression joints rated for 9,500 PSI versus standard concrete's 4,000 PSI capacity. Load distribution systems transfer wind forces to reinforced concrete footings, with test results indicating 3x greater impact absorption than post-and-rail systems. These advancements allow 25-year structural warranties without corrosion inhibitors or seasonal adjustments.

Material Science Comparison

Four material combinations dominate premium fencing markets. Steel and wood fences deliver natural aesthetics but require annual sealing against moisture penetration. UV-resistant polymer coatings extend wood durability from 7 to approximately 15 years. PVC and steel fence alternatives optimize chemical resistance using cellular PVC cores around steel skeletons, ideal for industrial environments. However, impact tests show PVC composites deform at 2,800 N force while brick-steel assemblies withstand over 12,000 N. Thermal performance data reveals brick-steel combinations maintain dimensional stability between -40°F and 140°F, unlike PVC which warps above 120°F or wood that contracts below freezing. Each configuration serves specialized applications based on environmental stressors.

Leading Manufacturers Analysis

| Manufacturer |

Tech Advantage |

Durability Index |

Custom Options |

Warranty |

| BarrierCraft |

Hot-dip galvanized steel with polymer infusion |

92/100 |

16 brick colors, 6 steel finishes |

30 years |

| FortiFence Systems |

Modular brick panels with interlocking steel |

87/100 |

4 brick textures, automated gates |

25 years |

| Perimeter Plus |

Carbon steel with ceramic coating |

84/100 |

Height variations (4-8 ft) |

20 years |

| Elemental Boundaries |

Recycled steel composite with thin-brick veneer |

78/100 |

12 veneer patterns |

15 years |

Durability Index measures wind/impact/moisture resistance per ASTM standards (Industry benchmark: 60/100 for vinyl fencing)

Customization Possibilities

Hybrid fencing allows precise environmental adaptation. Acoustic barriers integrate brick cores with steel studs, reducing highway noise by 42 decibels. Security versions feature reinforced steel pickets set in brick piers, defeating breaching attempts for over 9 minutes. Coastal specifications utilize grade 316 stainless steel runners within marine-grade mortar. Current innovations include photovoltaic brick panels charging perimeter lighting via steel conduit integration. Structural customization ranges from curved segments with tapered brick to cantilevered sections spanning 30 feet unsupported. Finishing options extend beyond material choices with inlaid mosaic patterns within brick faces or electrostatic powder-coated steel elements available in 200+ RAL colors.

Implementation Scenarios

Practical installations showcase performance in extreme conditions. Atlanta's Pine Hills Estates community combined brick base sections with ornamental steel tops, surviving Category 2 tornado winds with only cosmetic damage. Desert environments like Phoenix demonstrate brick-steel fences maintain integrity after 15+ years despite ultraviolet index averages of 11. Commercial applications in Chicago revealed 68% lower ice damage versus standalone steel barriers thanks to brick's thermal mass regulation. Coastal New England installations show less than 0.3% steel corrosion after a decade despite annual salt spray exposure exceeding 80 pounds per square mile. Institutional complexes utilize intercom conduits within brick pilasters and motion sensors within steel components creating seamless security integration.

Enduring Value in Brick and Steel Fence Solutions

Long-term performance analysis justifies composite fencing investments. Maintenance cycles prove cost-efficient: brick and steel fence

systems require inspection every 36 months versus vinyl's annual checking or wood's semiannual treatments. Projected 50-year ownership shows brick-steel combinations costing $18.44 per linear foot versus wood ($32.17) or wrought iron ($45.89). Structural warranties typically cover load-bearing components for the building's lifespan rather than product defects alone. Resale analyses consistently demonstrate properties with premium brick and steel perimeter barriers command 5-7% valuation premiums. Modern manufacturing now incorporates recycled steel and reclaimed brick aggregates, creating inherently sustainable barriers aligning with contemporary environmental goals while delivering timeless protection.

(brick and steel fence)

FAQS on brick and steel fence

Q: What are the main benefits of a brick and steel fence?

A: Brick and steel fences combine durability with aesthetic appeal. The brick provides structural stability and noise reduction, while steel adds security and a modern finish. This hybrid design suits both residential and commercial properties.

Q: How does a steel and wood fence compare to a brick and steel fence?

A: Steel and wood fences offer a rustic look and are lighter to install, but may require more maintenance. Brick and steel fences last longer and resist weathering better, though they typically cost more upfront.

Q: Is a PVC and steel fence more affordable than a brick and steel option?

A: Yes, PVC and steel fences are generally cheaper due to lower material and labor costs. However, they may lack the longevity and insulation benefits of brick and steel fences. Ideal for budget-conscious projects needing moderate durability.

Q: Which fence type—brick and steel or PVC and steel—is better for harsh climates?

A: Brick and steel fences excel in extreme weather, as brick resists moisture and steel withstands corrosion. PVC and steel may warp or fade over time in intense heat or cold, making them less durable long-term.

Q: Can a brick and steel fence be customized in design?

A: Absolutely. Brick can be colored or textured, and steel sections come in various patterns or powder-coated finishes. This allows for tailored aesthetics while maintaining structural integrity.