- Introduction to metal cages

and their growing importance

- The technology and engineering behind metal cages

- Detailed comparison among leading manufacturers

- Customization: Options and processes for tailored metal cages

- Wide-ranging applications including pets, industries, and storage solutions

- Case studies and success stories with measurable impacts

- Conclusion: Navigating the metal cages market for ideal solutions

(metal cages)

Introduction: The Role of Metal Cages in Modern Industries

Metal cages have become indispensable in numerous contemporary settings, providing secure, durable, and versatile solutions for containment and storage. Over the past decade, the demand for metal cages in various forms–from metal cages for sale targeting industrial users to specialized metal cages for dogs—has witnessed a significant surge. Driven by increasing adoption in logistics, manufacturing, animal care, and retail, the global market size for metal cages was valued at approximately $2.1 billion in 2023, with a projected CAGR of 5.9% through 2030, according to industry reports. This growth can be attributed to not only rising safety standards but also the adaptability and longevity these products offer. Whether it is for securing cargo or providing safe housing for animals, buyers now prioritize heavy-duty construction, modularity, and innovative locking mechanisms.

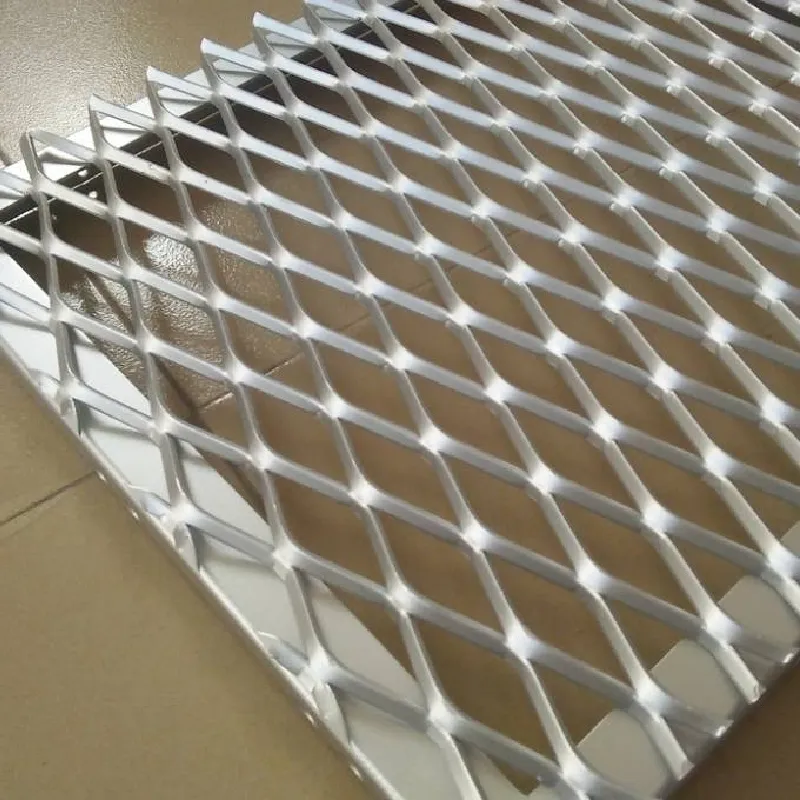

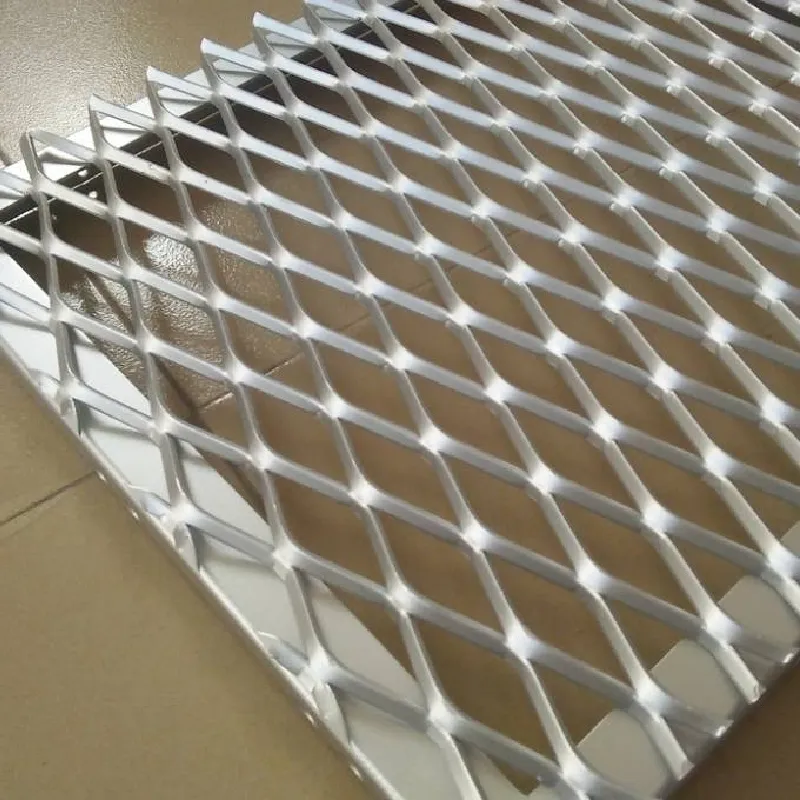

The Engineering Behind Metal Cages: Materials and Technical Superiority

Technical innovation has redefined the structure and utility of modern metal cages. Most metal cages today are fabricated using high-grade galvanized steel wire or stainless steel, offering corrosion resistance, structural integrity, and superior weight-to-strength ratios. For example, an industrial storage cage might integrate 4 mm diameter wire mesh with a powder-coated finish, resulting in a load capacity of over 800 kg. Meanwhile, specialized metal cages for dogs often incorporate rounded corners and non-toxic coatings to ensure safety and comfort. Advanced welding robotics have contributed to seamless joins and uniform mesh sizing—key factors for durability and tamper resistance.

Furthermore, contemporary designs allow for collapsible or foldable features, reducing transportation costs by up to 73% for bulk deliveries. Noise-dampening materials are now standard in pet cages, significantly lowering stress for animals during transport. These advances not only improve user experience but also minimize lifecycle maintenance and replacements, adding long-term value.

Manufacturer Comparison: Metal Cage Providers at a Glance

Choosing the right manufacturer is pivotal for ensuring quality and cost-effectiveness. Industry data shows divergence in production methodology, warranty, and service offerings among top brands. Below is a comparative table highlighting three leading manufacturers in the metal cage sector:

| Manufacturer |

Material Type |

Annual Output (units) |

Warranty (years) |

Customization Support |

Lead Time (days) |

Min Order Quantity |

| Fortress Metalworks |

Stainless Steel 304/316 |

130,000 |

3 |

Advanced (Full CAD/3D) |

14-21 |

10 |

| K9 Secure Fabricators |

Galvanized Steel |

95,000 |

2 |

Partial (Dimensional Edits) |

10-18 |

20 |

| InduGrid Systems |

Powder-coated Alloy |

150,000 |

5 |

Full (Material & Design) |

7-15 |

5 |

Reviewing performance metrics, InduGrid Systems leads in warranty and speed of delivery, offering the broadest customization and lowest MOQs. Fortress Metalworks stands out for marine-grade options and robust custom engineering. Buyers should consider the trade-offs between expedited delivery, breadth of design support, and longevity guarantees.

Customization Options: Tailoring Metal Cages to Unique Requirements

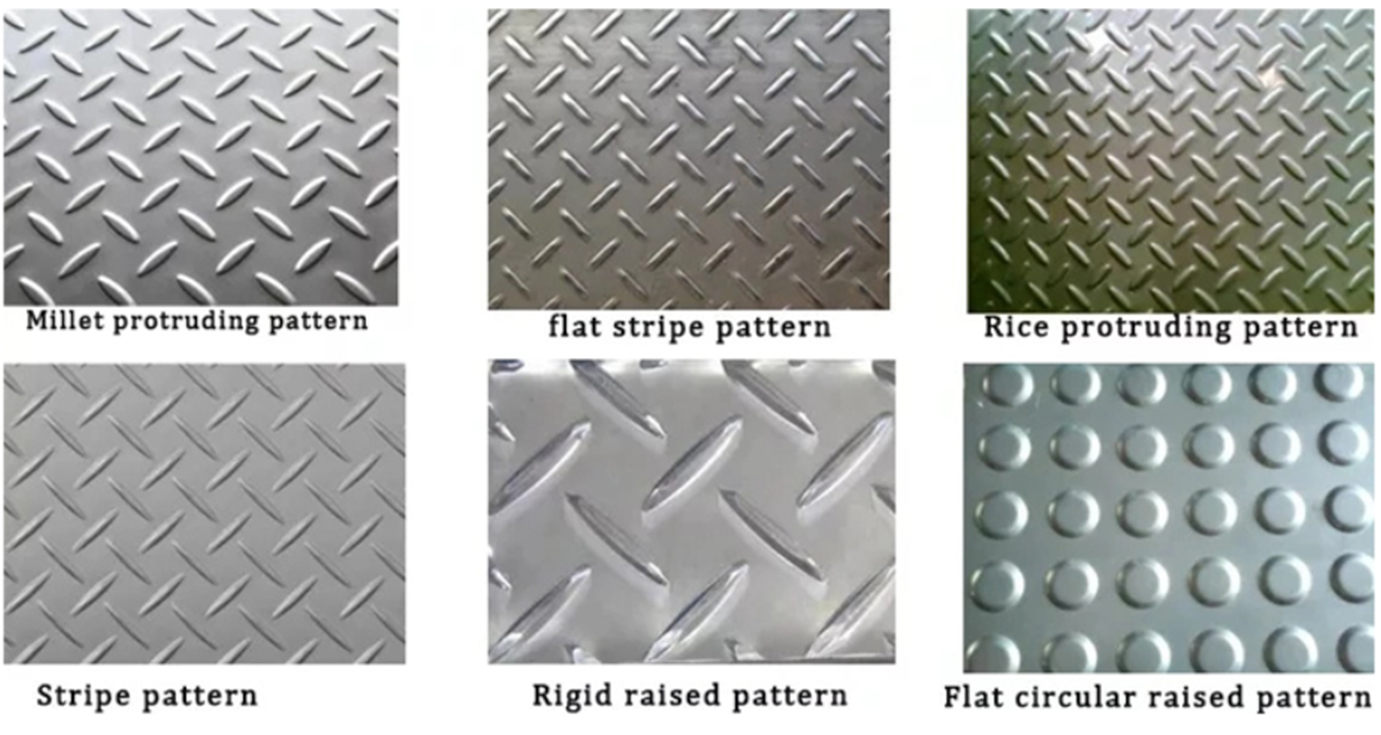

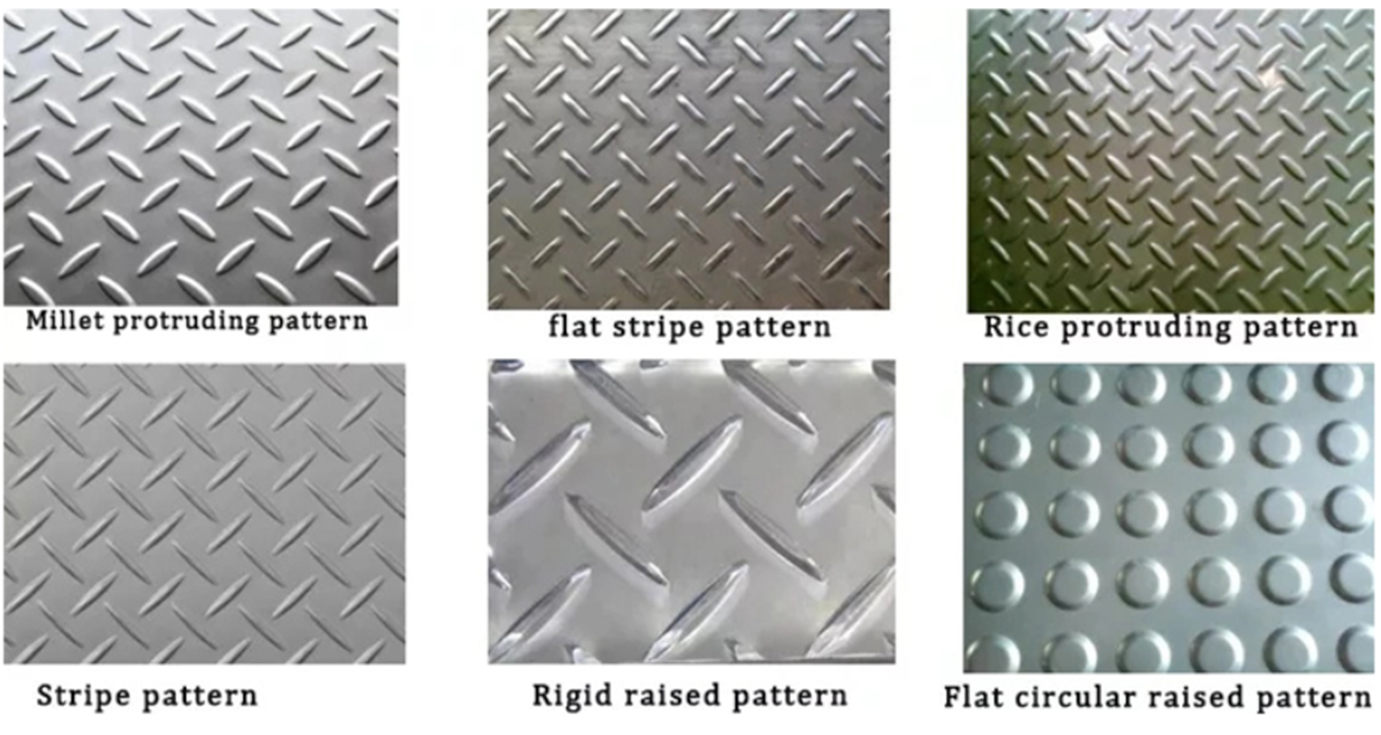

Not all applications are created equal; hence, the demand for tailored designs has spiked by over 32% in the last two years. Custom metal cages allow business and pet owners to specify dimensions, mesh aperture, access points, coatings, and branding, which can be critical for both operational efficiency and regulatory compliance. The process generally starts with a consultation and requirement mapping, followed by CAD-approved drawings and sample prototyping. Common customization inquiries include:

- Anti-rust treatments for outdoor or marine environment deployments

- Slot and door modifications for secure automation in warehouses

- Non-standard shape requests for vet clinics or shelter environments

- Logo laser engraving for corporate branding

In the pet sector, innovative optional features like divider panels, removable trays, and impact-resistant corners meet evolving safety and welfare guidelines. For industrial clients, custom cages often integrate RFID brackets for real-time asset tracking, which can reduce inventory losses by up to

17% annually.

Applications Beyond Containment: Industrial, Commercial, and Pet Sectors

The spectrum of metal cage application is vast. Primarily, industrial warehouses use robust cages for palletizing and material segregation, with some facilities reporting a 40% increase in storage space optimization after cage integration. Metal cages for sale in the commercial sector support everything from retail product displays to secure IT hardware housing.

In the pet arena, metal cages for dogs are subject to stringent welfare mandates; top-line models now feature soft-close latches and ventilation systems to comply with global transport standards. Other niche uses include:

- Laboratories employing bio-secure cages for animal research

- Breeding facilities utilizing stackable designs for efficient animal management

- Homeowners choosing designer cages for pet aesthetics and safety

- Event organizers demanding portable, modular fencing for crowd control

The embedding of IoT-enabled security and environmental sensors in metal cages is an emerging trend, enabling temperature, humidity, and even animal activity monitoring on a remote basis.

Real-World Case Studies: Proven Impact and Measurable ROI

The effectiveness of high-quality metal cages is increasingly quantifiable. Consider the following case studies:

Industrial Logistics: A global automotive supplier transitioned from conventional wood crates to metal cages, slashing returnable container costs by 53% and decreasing internal part damage by 16% within a year.

Veterinary Hospitals: A major animal hospital chain upgraded to custom powder-coated metal cages for dogs, leading to a 25% rise in patient turnover and a 0% incident rate for escape-related injuries over two years.

Retail Storage: An electronics retailer retrofitted inventory rooms using collapsible metal cages, freeing up 600 sq. ft of additional space in a single flagship location, supporting year-on-year revenue growth.

These success stories are supported by feedback indicating improved workflow efficiencies, reduced loss rates, and enhanced user peace of mind–tangible business advantages extending beyond the purchase price.

Conclusion: Choosing the Right Metal Cages for Diverse Needs

Navigating the continually evolving marketplace for metal cages requires careful consideration of material strength, design flexibility, and aftersales support. Whether searching for metal cages for sale to suit rigorous industrial settings or investing in high-quality metal cages for dogs, it is crucial to evaluate manufacturing credentials, customization pathways, and proven impact through real-world application. With ongoing advances in smart cage technologies and sustainable production processes, organizations and consumers alike can find solutions that combine cost-efficiency, compliance, and outstanding durability for every containment or storage challenge.

(metal cages)

FAQS on metal cages

Q: What are metal cages used for?

A: Metal cages are commonly used to safely contain animals, store goods, or organize materials. They provide sturdy and durable protection. Popular uses include kennels and warehouse storage.

Q: Where can I find metal cages for sale?

A: You can find metal cages for sale online, at pet supply stores, or through industrial equipment retailers. Many suppliers offer customization options. Always compare prices and specifications before purchasing.

Q: Are metal cages suitable for dogs?

A: Yes, metal cages for dogs are widely used for training, transport, and safety. They are durable and easy to clean. Choose an appropriately sized cage for your dog’s comfort.

Q: What sizes do metal cages come in?

A: Metal cages are available in various sizes, from small enclosures for pets to large industrial storage cages. Measure your space or pet to select the right size. Custom sizes are also offered by some vendors.

Q: How do I maintain a metal cage?

A: Regularly clean the cage with mild soap and water to prevent rust or buildup. Check for loose parts or damage frequently. Keeping it dry enhances longevity and safety.