- Introduction: Grating Galvanized Steel and Its Growing Demand

- Technical Excellence in Galvanized Steel Grating

- Market Price Dynamics: Analyzing Galvanized Steel Grating Prices

- Comparative Analysis: Leading Hot Dip Galvanized Steel Grating Manufacturers

- Customization Options and Unique Solutions in Steel Grating Galvanized

- Real-World Application Cases of Galvanized Steel Gratings

- Conclusion: Investing in Grating Galvanized Steel for Long-Term Value

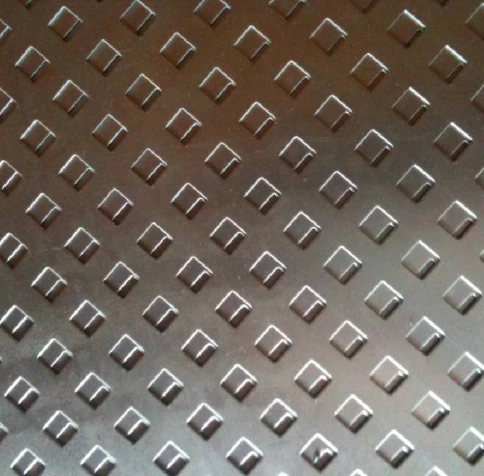

(grating galvanized steel)

Introduction: Exploring the Surging Popularity of Grating Galvanized Steel

In recent years, the use of grating galvanized steel

has surged across industrial, commercial, and infrastructural sectors worldwide. With the global industrial flooring market expected to exceed $12 billion by 2027, galvanized steel gratings are at the forefront of this growth, driven by their exceptional durability, corrosion resistance, and maintenance efficiency. These structural platforms, typically fabricated with hot dip galvanization, offer both safety and longevity, distinguishing themselves in harsh working environments. The integration of advanced manufacturing technologies has further optimized their performance, making them a preferred choice for projects requiring robust load-bearing capacity and economical lifetime costs.

Technical Excellence in Galvanized Steel Grating

The success of modern galvanized steel grating lies in the precise application of hot dip galvanizing technology. The steel surface, once thoroughly cleaned, is immersed in molten zinc at approximately 450°C (842°F). This process forms a zinc-iron alloy layer that shields the steel from corrosive elements. According to ASTM A123/A123M standards, the average zinc coating weight ranges from 610 to 900 g/m², ensuring high-performance corrosion protection for up to 50 years in moderately aggressive environments.

Galvanized steel grating panels are designed in various bar sizes and thicknesses. Typical specifications include a load bar size of 25mm x 3mm or 30mm x 5mm, and cross bar spacing between 40mm and 100mm. The open grid configuration minimizes dirt accumulation and facilitates drainage, proving especially advantageous in water treatment plants, oil refineries, and mines. The hot dip galvanized finish also enhances mechanical resilience, enabling the grating to resist impacts, heavy traffic, and chemical exposures.

Market Price Dynamics: Analyzing Galvanized Steel Grating Prices

Understanding galvanized steel grating prices is essential for project budgeting and procurement. Pricing varies based on factors like steel grade, bar dimensions, galvanization thickness, production volumes, and customization requirements. Global market reports indicate that in 2024, the average price of hot dip galvanized steel grating ranges from $800 to $1,050 per metric ton.

The following table shows a comparative overview based on different regions and specifications:

| Region |

Standard Size Grating (per ton) |

Premium Heavy Duty (per ton) |

Thr. Zinc Coating (g/m²) |

Delivery Lead Time |

| North America |

$1,000 |

$1,250 |

610–900 |

4–6 weeks |

| Europe |

$970 |

$1,180 |

615–850 |

3–5 weeks |

| Asia-Pacific |

$830 |

$1,050 |

680–930 |

2–4 weeks |

| Middle East & Africa |

$890 |

$1,130 |

600–820 |

5–7 weeks |

These figures emphasize the impact of regional manufacturing capabilities, raw material costs, and logistical considerations on final pricing. It is noteworthy that galvanized steel grating prices fluctuate with global steel trends as well as project-specific volume agreements.

Comparative Analysis: Leading Hot Dip Galvanized Steel Grating Manufacturers

Selecting a reliable supplier for hot dip galvanized steel grating substantially influences long-term project success. The market comprises several established manufacturers, each with distinct technical and operational strengths.

| Manufacturer |

Annual Capacity (tons) |

Standard Compliance |

Customization Capability |

Key Markets |

| AMICO (USA) |

100,000+ |

ASTM, NAAMM MBG531 |

High |

North America, Europe |

| Yantai Xinke (China) |

60,000+ |

GB/T 13912, Euro Norms |

Very High |

Asia-Pacific, Middle East |

| Lionweld Kennedy (UK) |

50,000+ |

BS EN ISO 1461 |

Medium |

Europe, Africa |

| MEISER (Germany) |

90,000+ |

DIN, EN, ASTM |

High |

Global |

While each manufacturer upholds international quality standards, factors such as lead time, design flexibility, and after-sales support vary widely. Projects demanding intricate load or geometry requirements often benefit from suppliers who excel in custom fabrication.

Customization Options and Unique Solutions in Steel Grating Galvanized

Engineering projects rarely adopt a one-size-fits-all approach, and steel grating galvanized solutions exemplify the importance of customization. Advanced digital design tools allow for precise modeling of grating patterns, ensuring compatibility with unique architectural and industrial layouts.

Typical customization features include:

- Load bar type: plain, serrated, or I-bar.

- Bar spacing configurations: up to 100mm depending on load requirements.

- Panel sizes: manufactured to fit specific stair treads, trenches, or mezzanine walkways.

- Edge banding and cut-outs tailored for complex junctions.

- Surface treatment options: anti-slip coatings, powder coatings besides galvanization.

These adaptations enable the grating to serve a wide range of functional, safety, and aesthetic requirements. According to a 2023 construction survey, over 65% of infrastructure projects commissioned customized steel gratings to optimize fit and performance.

Real-World Application Cases of Galvanized Steel Gratings

The versatility of galvanized steel gratings is evident across multiple real-world scenarios, from industrial flooring to architectural facades. Here are some representative applications:

-

Offshore Platforms: Extensively utilized for walkways, handrails, and emergency exits due to their non-slip surface and ability to withstand severe marine corrosion. Notably, a major North Sea oil platform reported zero grating maintenance incidents over five years post-installation.

-

Urban Infrastructure: Major metropolitan subway systems use galvanized steel gratings for ventilation covers and service walkways, with an average lifespan exceeding 35 years and negligible structural degradation.

-

Manufacturing Facilities: Automotive and chemical plants favor heavy-duty gratings for flooring in production zones where chemical splashes, wheel loading, and frequent cleaning are prevalent.

-

Commercial Spaces: Custom grating designs have made a mark in shopping mall exteriors and public gardens, blending safety with visual appeal.

Each project underscores the material’s capacity for safety assurance, compliance with stringent standards, and remarkable lifecycle cost savings.

Conclusion: Investing in Grating Galvanized Steel – A Strategic Decision

In summary, grating galvanized steel stands as a resilient, cost-effective, and sustainable solution for diverse construction and engineering challenges. With proven technological advantages—ranging from robust corrosion resistance to engineering flexibility—and supported by leading global manufacturers, this material adapts seamlessly to both standard and specialized applications. Market data underscores stable galvanized steel grating prices, making it viable for both large-scale infrastructure and compact architectural ventures. As real-world case studies and technical benchmarks confirm, investing in high-quality steel grating galvanized components provides enhanced safety, reduced maintenance, and long-term economic value for forward-thinking businesses and developers.

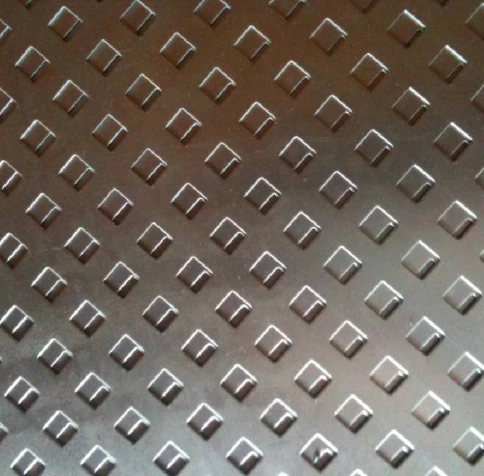

(grating galvanized steel)

FAQS on grating galvanized steel

Q: What is grating galvanized steel?

A: Grating galvanized steel refers to steel grating that has been coated with a layer of zinc through galvanization. This improves corrosion resistance and durability. It is widely used for walkways, platforms, and drainage covers.

Q: How are galvanized steel grating prices determined?

A: Galvanized steel grating prices depend on factors such as material specifications, size, thickness, and quantity. Additional customization can also affect the cost. Bulk orders may offer better pricing.

Q: What is hot dip galvanized steel grating?

A: Hot dip galvanized steel grating is steel grating submerged in molten zinc to provide a thick protective coating. This process enhances resistance to rust and extends product lifespan. It is ideal for outdoor or harsh environments.

Q: What are the advantages of steel grating galvanized?

A: Steel grating galvanized offers excellent corrosion protection and low maintenance needs. It is strong, durable, and suitable for various industrial applications. The zinc coating also provides an attractive finish.

Q: Where can I buy galvanized steel grating?

A: You can purchase galvanized steel grating from specialized steel suppliers, construction material dealers, or online industrial marketplaces. Ensure to specify your required sizes and specifications. Many suppliers also offer custom fabrication services.