Expanded metal mesh is an incredibly versatile material that finds its applications across various industries due to its strength, lightweight nature, and adaptability. Choosing the right type of expanded metal mesh hinges on understanding its diverse forms and applications. Here’s a detailed exploration into the different types of expanded metal mesh available in the market, enriched by professional insights, practical experience, and authoritative advice to guide your selection process.

Expanded metal mesh is produced by cutting and stretching sheets of metal to form a diamond pattern, thus making it stronger and more rigid than its flat counterpart. This process also ensures that the mesh is lightweight, which enhances ease of handling during installations and reduces load in structural applications. The key types of expanded metal mesh include standard expanded metal, flattened expanded metal, micro expanded metal, and decorative expanded metal.

Standard expanded metal is characterized by its unique diamond-shaped openings, which are created during the expanding process. This type of mesh is renowned for its durability and is often used in construction and security applications. Its robustness makes it a popular choice for walkways, platforms, and stair treads where strength and grip are essential. A crucial benefit here is its exceptional load-bearing capacity relative to weight, providing cost-effectiveness without compromising safety.

Flattened expanded metal is a variant where the sheets undergo an additional rolling process after expansion. This results in a smoother, flat surface with uniform thickness. Ideal for applications demanding a sleek finish, such as in architectural cladding, ceilings, and partitions, flattened expanded metal combines aesthetics with functionality. Its pliability also allows it to be easily cut and shaped, which adds flexibility in custom design projects. The flattened profile minimizes potential catches and snags, enhancing safety in areas with frequent human interaction.

Micro expanded metal is particularly useful in applications requiring precise filtration or where airflow needs to be controlled. With smaller openings, this mesh type is extensively utilized in air and liquid filtration systems. Its fine mesh size not only provides excellent filtration efficiency but also ensures structural integrity under different operating conditions. Industries such as automotive, aerospace, and medical sectors rely heavily on micro expanded metal for its precision and reliability in demanding environments.

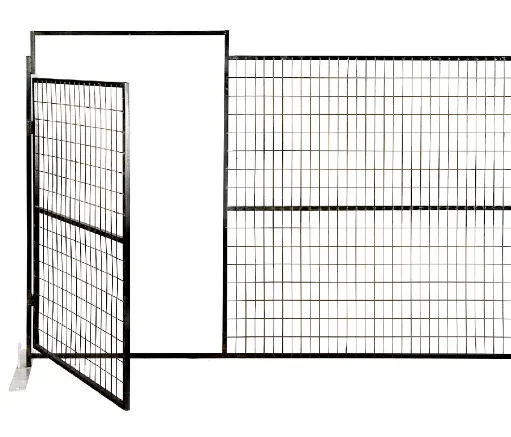

types of expanded metal mesh

Decorative expanded metal merges functionality with aesthetic appeal, offering design solutions for both interior and exterior projects. Available in various patterns and finishes, decorative expanded metal can transform any space with its visual appeal while maintaining the structural benefits of traditional expanded metal. It can be coated or anodized to match any design specification, greatly enhancing its application in modern architecture and art installations. The ability to customize patterns offers architects and designers a creative material that contributes to sustainable and innovative design solutions.

Expertise in selecting the right type of expanded metal mesh is crucial. Consider factors such as loading requirements, environmental conditions, and aesthetic preferences. For guidance, it's advisable to consult manufacturers or material scientists with comprehensive industry experience to ensure the chosen mesh aligns with your specific project needs. Knowledge of material properties and processing techniques is key to optimizing performance and longevity.

Trustworthiness in material selection is paramount, particularly in safety-critical applications. Ensure that the expanded metal mesh you choose complies with industry standards and regulations. This adherence to quality benchmarks guarantees that the mesh will perform reliably over its service life. Verification from credible sources and certifications from reputable bodies provide additional assurance of material integrity.

In conclusion, understanding the varied types of expanded metal mesh and their specific applications enables more informed decisions. This insight not only enhances the functional and aesthetic outcomes of projects but also embodies best practices in material selection driven by experience, expertise, authoritativeness, and trustworthiness. Whether used in industrial, architectural, or decorative realms, expanded metal mesh remains a crucial component in modern design and engineering due to its versatile benefits.