Thin iron wire is an essential component across numerous industries, known for its versatility, strength, and conductivity. As businesses strive to create products that are efficient and reliable, the unique properties of thin iron wire make it an invaluable resource.

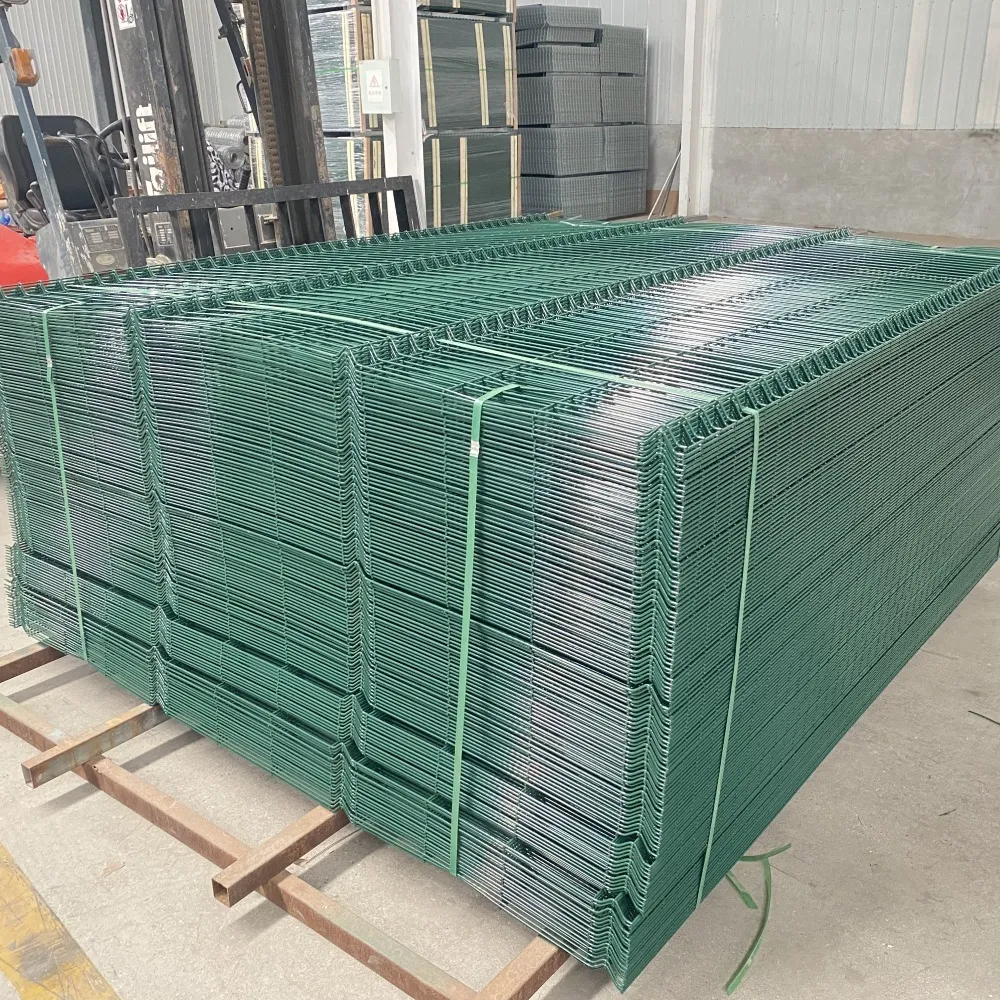

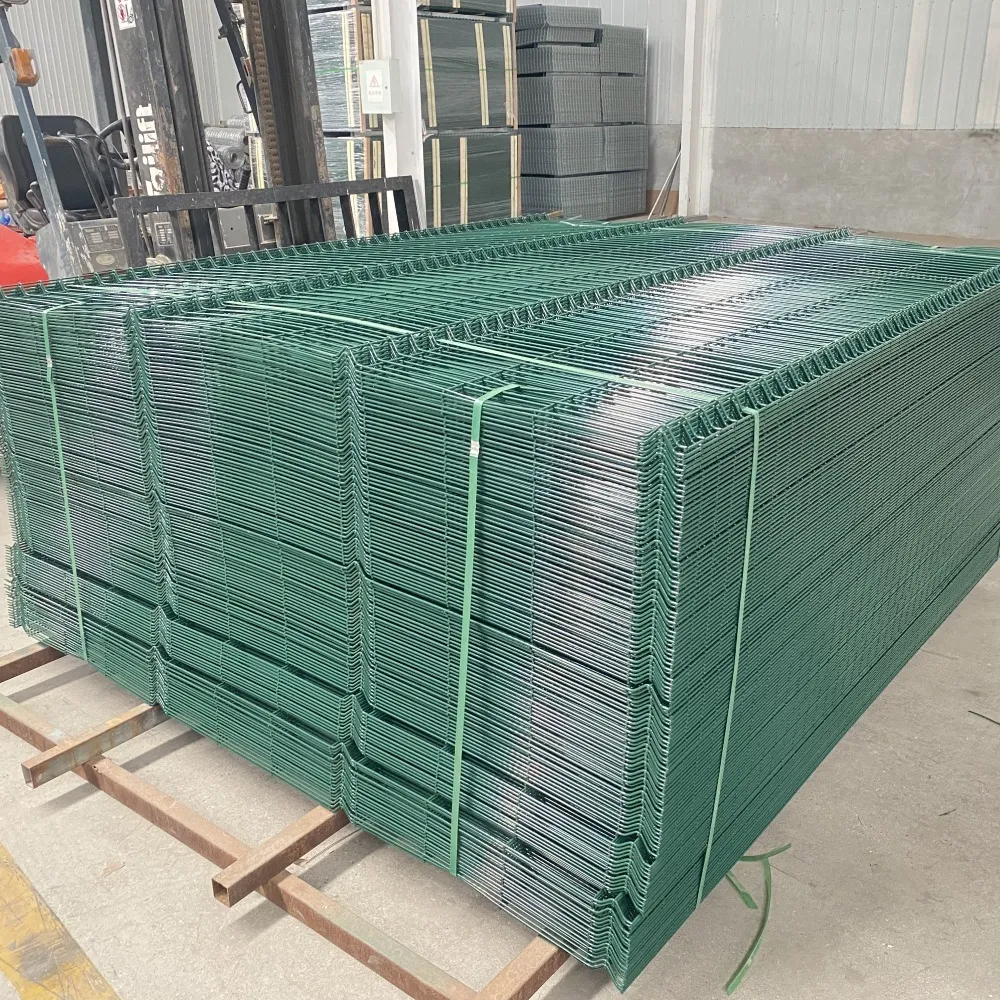

In the industrial landscape, thin iron wire is prized for its tensile strength and ductility, making it an excellent choice for use in applications requiring durability and flexibility. This wire is frequently utilized in the production of wire mesh, fencing, and even in the core of electrical cables. Its adaptability extends to various processes, where it's transformed and engineered to meet specific project requirements.

In manufacturing, thin iron wire serves as a key material in assembling components that demand precision. Due to its magnetic properties, it is often employed in electrical engineering, particularly in winding inductors and transformers. Such use harnesses its ability to conduct electricity efficiently, allowing for the smooth operation of electrical devices. Beyond this, its ease of handling and manipulation makes it an excellent choice for experimental prototypes in research and development environments.

The construction industry benefits greatly from thin iron wire's contributions. Its ability to reinforce structural frameworks provides additional stability to concrete and masonry work.

When used in conjunction with other materials, it can strengthen the overall integrity of a building structure. This adaptability is especially crucial in earthquake-prone areas where flexibility and strength can significantly mitigate structural damage.

For artistic endeavors, thin iron wire offers remarkable properties that appeal to sculptors and artisans. Its pliability allows for fine detail and intricate designs, enabling artists to create dynamic and expressive pieces. The wire can be bent, twisted, and shaped with ease, yet maintains form once set, making it a favored medium for creatives worldwide. Furthermore, its natural finish or ability to hold various coatings enhances its aesthetic versatility.

thin iron wire

Agricultural applications frequently make use of thin iron wire due to its durability and resistance to environmental factors. It is commonly used in the creation of trellises and support structures for plants, aiding in efficient vertical growth and improving yield. The wire’s resilience under varying weather conditions ensures long-lasting support for crops, proving indispensable to farmers.

In a realm where sustainability is paramount, thin iron wire’s recyclability cannot be overstated. Given the global emphasis on reducing waste and promoting eco-friendly practices, iron wire's ability to be repurposed aligns with environmentally conscious business strategies. This sustainability not only minimizes environmental impact but also translates into cost savings over time, enhancing its appeal to companies mindful of both profits and sustainability.

Despite its many advantages, sourcing high-quality thin iron wire requires attention to detail and a rigorous selection process. For businesses, partnering with reputable suppliers who offer certified products is essential. Ensuring compliance with relevant standards guarantees that iron wire will not only meet but exceed performance expectations.

In summary, thin iron wire stands out as more than just a basic industrial material. Its strength, flexibility, and adaptability across various domains highlight its indispensable role in innovation and development. By leveraging its unique characteristics, industries can enhance efficiency, sustainability, and product reliability. As businesses continue to seek materials that deliver precise functionality while aligning with broader environmental goals, thin iron wire remains a top contender for achieving such aims.