Thick metal mesh stands out as a fundamental component across various industries, providing solutions with its robust and versatile design. This product has gained popularity due to its diverse applications, unparalleled durability, and essential role in both modern and traditional sectors. This article delves deep into the significance of thick metal mesh, offering insights from extensive experience, providing expert opinions, emphasizing authority, and ensuring trustworthiness.

Thick metal mesh is engineered to meet the demanding requirements of different sectors, offering a sturdy solution that withstands significant stress and environmental challenges. Its applications range from construction reinforcement to industrial filtration, making it indispensable for numerous engineering projects. Whether used in infrastructure development or delicate filtration systems, its reliability is unparalleled.

Drawing from extensive industry experience, thick metal mesh is crafted from high-quality metals such as stainless steel, galvanized steel, or aluminum.

Each material choice is tailored to suit specific application needs. Stainless steel, for instance, is known for its corrosion resistance, making it ideal for environments with high moisture exposure. In contrast, galvanized steel offers a cost-effective solution without compromising strength, suitable for large-scale constructions where budget constraints meet performance needs.

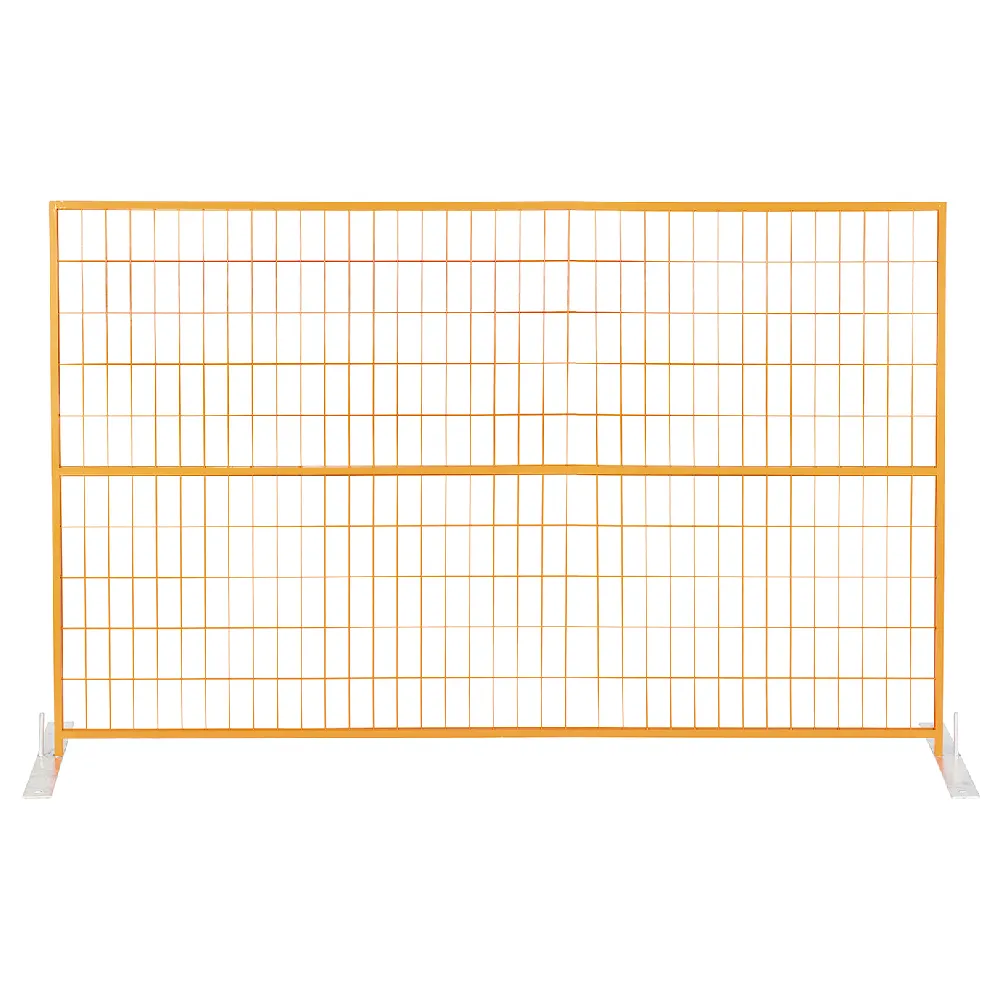

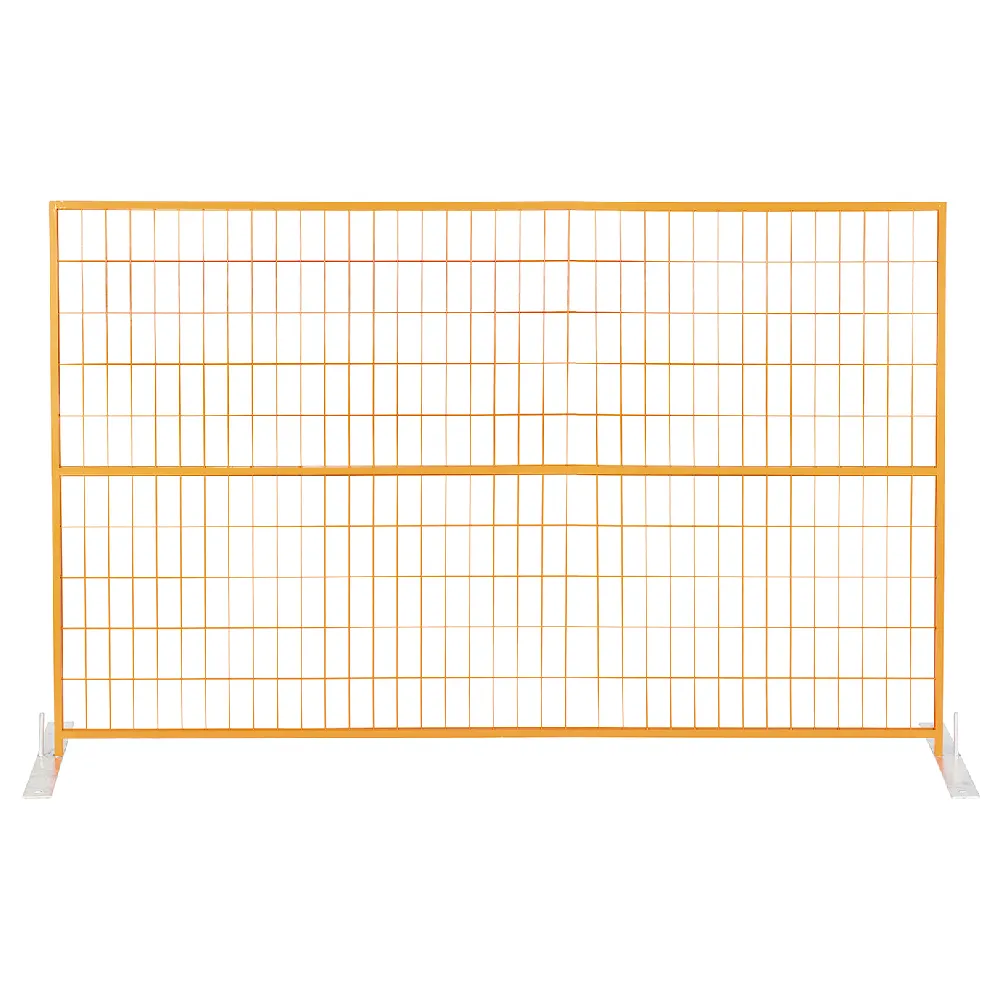

In construction, thick metal mesh plays a pivotal role in ensuring structural integrity. It is often used in reinforced concrete applications where it provides additional strength, supporting the overall structure and extending its lifespan. Expert builders understand the significance of integrating metal mesh into designs, emphasizing how it helps distribute weight evenly, control cracking, and mitigate damage during natural disasters like earthquakes.

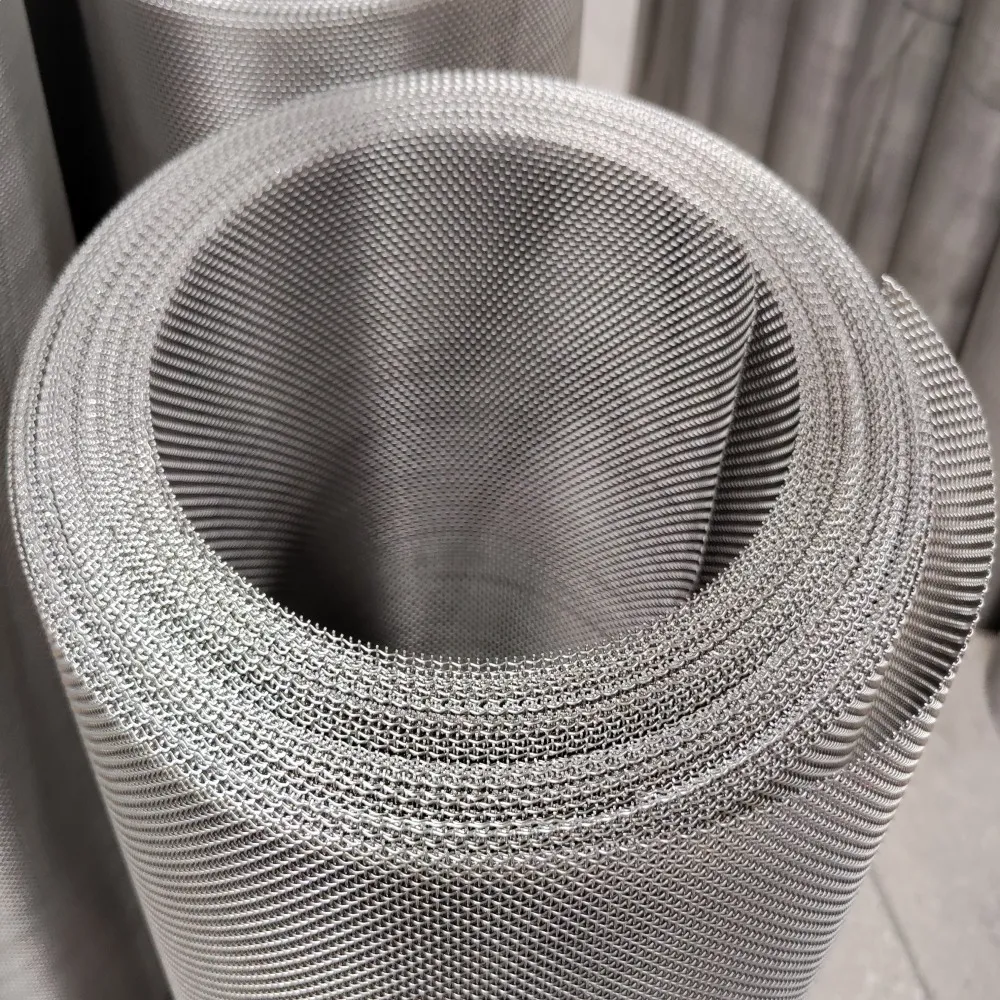

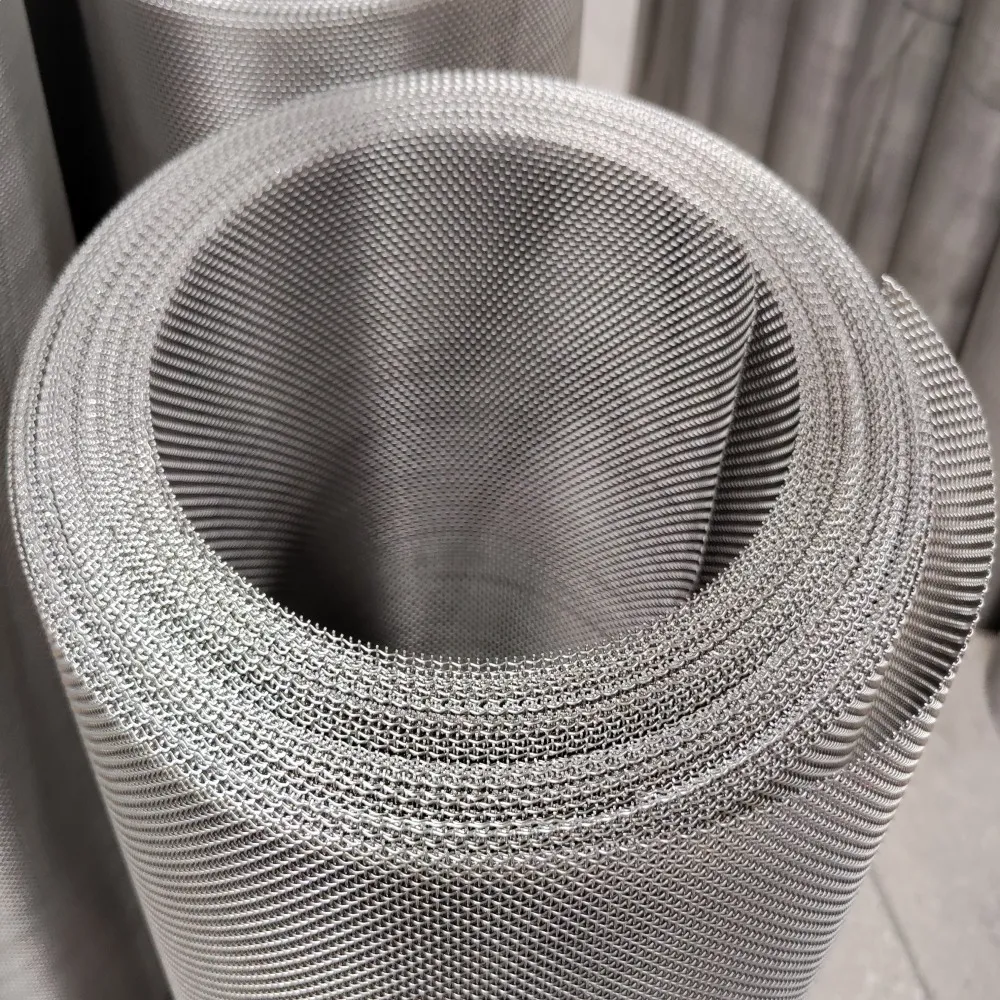

Industrially, thick metal mesh finds its niche in filtration systems. It provides a practical solution for filtering particles while allowing fluids to pass through with minimal resistance. Its adaptability in processing varying material grades and thicknesses enables a tailored approach to filtration needs, from water purification systems to oil refineries. By consulting industry experts, firms ensure that their filtration systems are optimized for efficiency and longevity using thick metal mesh.

thick metal mesh

Beyond its practical applications, the authority of thick metal mesh lies in its historical usage and continuous innovation. Historically, metal mesh has been used in armor and architecture, testifying to its enduring strength and versatility. Today’s advancements incorporate technology that enhances metal mesh with coatings that resist UV radiation, extreme temperatures, and chemical exposure. This evolution highlights its capacity to adapt to modern challenges while maintaining its revered robustness.

Trust in thick metal mesh is fostered through stringent quality assurance processes. Manufacturers emphasize rigorous testing protocols that ensure each mesh's consistency and integrity. These tests measure tensile strength, resistance to corrosion, and load-bearing capabilities, assuring customers of the product’s reliability. Selecting manufacturers who prioritize these quality checks guarantees that consumers are investing in a product that will perform under pressure and deliver consistent results.

For businesses and consumers alike, choosing thick metal mesh involves considering several factors the mesh’s intended use, environmental factors, and specific strength requirements. Engaging with industry experts during the selection process is crucial to identify the best material choice and mesh configuration. These consultations provide tailored solutions, maximizing the mesh’s effectiveness and ensuring a long-term investment.

To conclude, thick metal mesh is not merely a material but a cornerstone in various industrial and construction applications. Its proven track record, coupled with continuous innovation and rigorous quality standards, cements its status as a reliable choice. By understanding its applications and consulting with experts, businesses can harness the full potential of thick metal mesh, optimizing their projects for success. As industries evolve, the role of thick metal mesh remains indispensably foundational, today and into the future, ensuring stability, performance, and safety across a multitude of applications.