Metal mesh, a crucial component in reinforced concrete structures, provides enhanced strength, durability, and stability to concrete slabs. Over the years, it has gained widespread usage in the construction industry, acting as a pivotal element that meets modern engineering demands. This article delves into the indispensable role of metal mesh in concrete slabs, informed by the latest advancements, professional insights, and real-world applications to provide comprehensive expertise and trustworthiness.

Concrete slabs, foundational to many constructions, are often subject to hefty loads and environmental stresses. When reinforced with metal mesh, these slabs exhibit exceptional load-bearing capabilities. Metal mesh, often fabricated from steel, acts as a tension device within the concrete, countering the material's inherent brittleness. This synergy between concrete and metal ensures the slab’s capacity to withstand tensile stress, ultimately extending its lifespan and preserving the structural integrity of buildings and pavements.

Incorporating metal mesh into concrete slabs requires expertise, balancing precision with practicality. Experts recommend positioning the mesh at an optimal depth within the slab, typically around the middle third of the slab's height. This placement is critical; it ensures that the mesh provides maximum reinforcement where tensile forces are greatest. By preventing the occurrence of cracks and mitigating potential ruptures, metal mesh plays a strategic role in maintaining the aesthetic and functional quality of concrete surfaces.

From residential driveways to expansive commercial floors, the use of metal mesh in enhancing slab performance is well-documented. In residential contexts, homeowners appreciate the long-term durability and reduced maintenance costs associated with mesh-reinforced slabs. For commercial and industrial applications, where the stakes are higher, engineers utilize metal mesh to guarantee compliance with safety standards and load requirements. Warehouses, for instance, often feature concrete slabs reinforced with metal mesh to support heavy machinery and dynamic loads, proving their utility in demanding environments.

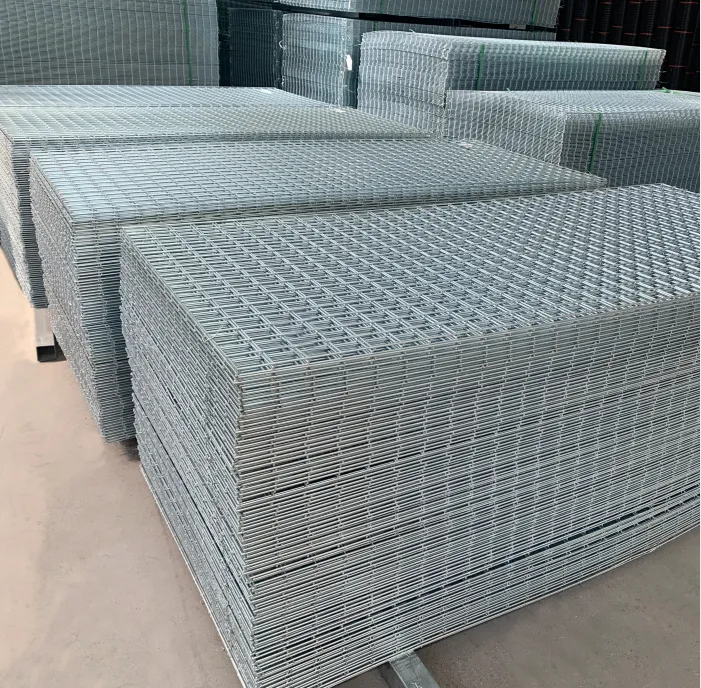

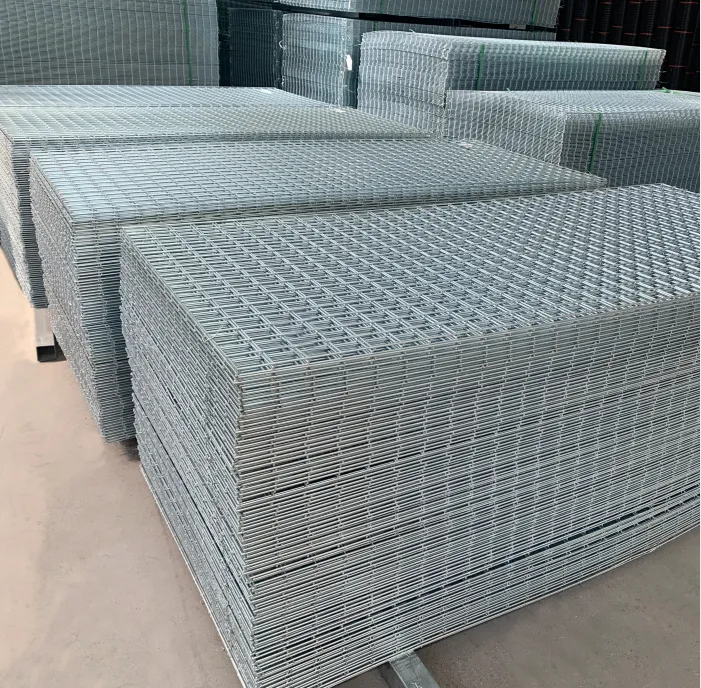

metal mesh for concrete slab

Of equal importance is the quality and specification of the metal mesh itself. Construction experts emphasize the significance of choosing the right gauge and material composition. The wire diameter, opening size, and the overall configuration of the mesh should be meticulously matched to the specific demands of the project. High-quality meshes are galvanized or coated with corrosion-resistant materials, enhancing their longevity and ensuring reliable performance even in harsh conditions.

The adoption of metal mesh is underpinned by case studies and empirical data highlighting its efficiency. Studies have shown that concrete slabs with integrated metal mesh exhibit reduced shrinkage cracking and improve stress distribution compared to non-reinforced slabs. Construction professionals often reference these findings to advocate for the inclusion of metal mesh in new-builds and renovation projects alike, buttressing their recommendations with solid evidence that underscores the product's effectiveness.

Beyond the technical aspects, the integration of metal mesh in concrete slabs speaks to broader trends in sustainable construction practices. By prolonging the service life of concrete slabs and reducing the need for frequent repairs, metal mesh contributes positively to environmental conservation efforts. This aligns with contemporary architectural philosophies that emphasize sustainability without compromising structural excellence.

The role of metal mesh in concrete slabs is not one-dimensional but multi-faceted, contributing significantly to the sustainability, durability, and performance of modern infrastructure. Its integration demands a nuanced understanding of both materials science and practical construction skills. As the construction industry continues to evolve, the importance of reliable techniques and materials like metal mesh remains paramount. Whether for a homeowner aiming for a resilient driveway or an engineer planning an industrial floor, metal mesh stands as a testament to innovation and enduring quality in construction.