When it comes to industrial and commercial projects requiring durable and reliable materials, hot dipped galvanized wire mesh stands out as a top contender. This robust, rust-resistant material has become the cornerstone of various applications due to its unmatched properties. To truly appreciate the multitude of advantages offered by hot dipped galvanized wire mesh, it's essential to delve into the practical experiences, specialized knowledge, authoritative insights, and the built trustworthiness that sets it apart from other materials.

Starting with the Experience aspect, contractors and engineers across different sectors have consistently praised hot dipped galvanized wire mesh for its longevity. Unlike other materials that require frequent maintenance or replacements, this type of wire mesh resists corrosion effectively thanks to the zinc coating gained through the hot-dip galvanizing process. Its ability to withstand harsh environmental conditions without compromising structural integrity has saved companies countless hours and resources, leading to more cost-efficient operations. Real-world applications, such as in the construction of fencing in high-moisture areas or reinforcement in concrete structures, showcase the material's adaptability and performance.

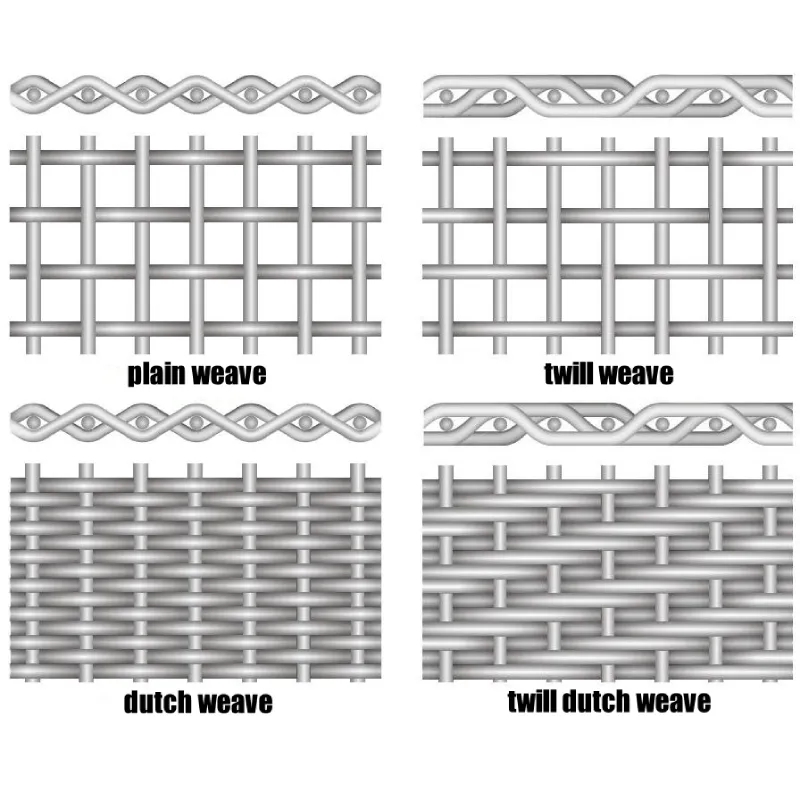

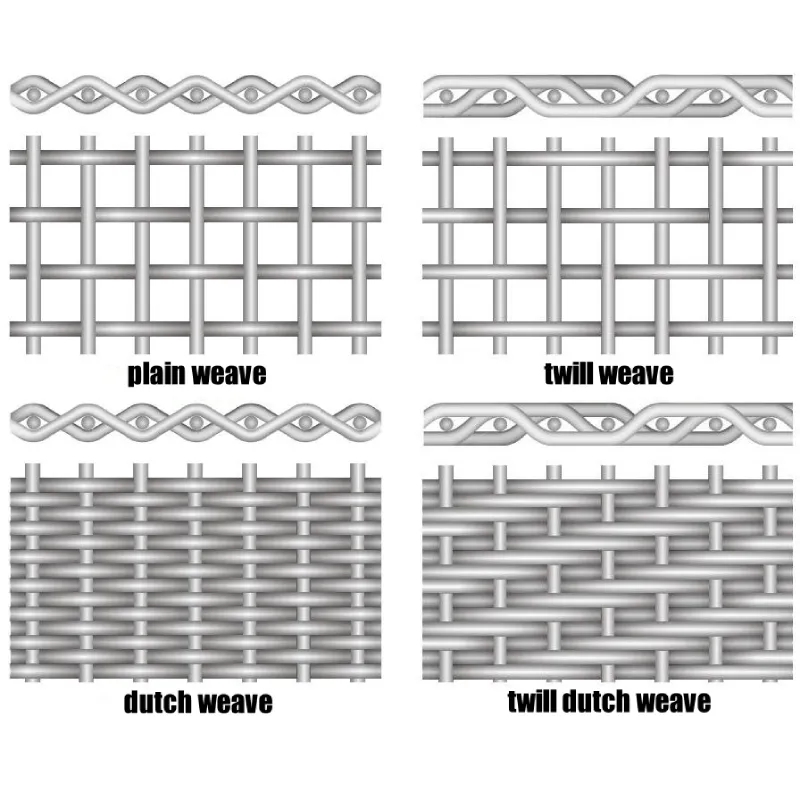

From an Expertise perspective,

understanding the galvanization process is essential to appreciate why this wire mesh excels in its applications. Hot dipping involves submerging the mesh into molten zinc, ensuring an even coat that bonds to the steel. This process not only enhances the tensile strength of the wire but also provides uniform protection against chemical and atmospheric elements. Industry experts emphasize the importance of the zinc layer's thickness, stating that the standard measurement typically falls between 50 to 100 microns depending on the intended use, thus providing a customizable approach to different project needs.

hot dipped galvanized wire mesh

Diving into Authoritativeness, it's worth noting that hot dipped galvanized wire mesh is compliant with international standards like ASTM A123 and A153. These standards guarantee the product's quality and suitability for demanding applications. Moreover, several authoritative bodies recognize its effectiveness in safeguarding infrastructures, notably in sectors like agriculture, mining, and construction. Research published in industry journals often highlights the extended life span of galvanized products compared to non-treated options, thereby confirming its reliability and efficiency.

Trustworthiness is a critical factor in material selection, and hot dipped galvanized wire mesh has earned its place through proven performance and consistent quality. Manufacturers and suppliers maintain transparency in their production processes, allowing end-users to verify the material's conformity to specific standards. Furthermore, the track record of successful projects and endorsements from industry leaders reinforce its credibility. Users can confidently rely on hot dipped galvanized wire mesh, knowing it delivers on promises of durability and resilience under diverse conditions.

In conclusion, choosing hot dipped galvanized wire mesh translates to investing in a material renowned for its excellent resistance to wear and tear. Its broad application across various industries, coupled with the in-depth expertise backing its development, highlights its effectiveness. The blend of authoritative validation and proven experience ensures that users receive a trustworthy product capable of meeting and exceeding expectations in both performance and value.