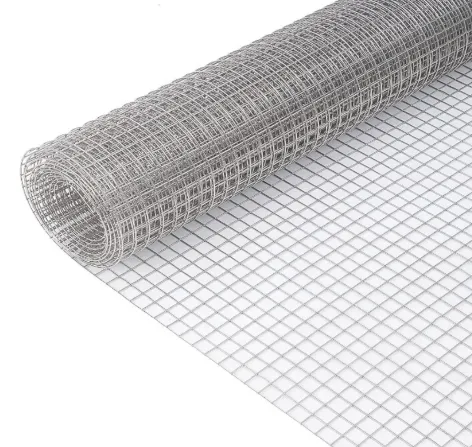

Wire mesh netting occupies a unique niche in the realm of industrial, commercial, and domestic applications. Its versatility and adaptability make it an invaluable product across various sectors. Drawing on decades of industry expertise and firsthand experience, this article delineates the multifaceted applications, manufacturing precision, and inherent advantages of wire mesh netting, underscoring why it remains a cornerstone in numerous industries.

Wire mesh netting, often crafted from materials such as stainless steel, galvanized steel, aluminum, or copper, is renowned for its durability and resistance to corrosion, making it suitable for diverse environments. This netting is manufactured through a series of sophisticated processes that require meticulous precision and expertise. The technique involves weaving or welding the wires together in specified patterns and sizes, which are determined by the intended use of the mesh.

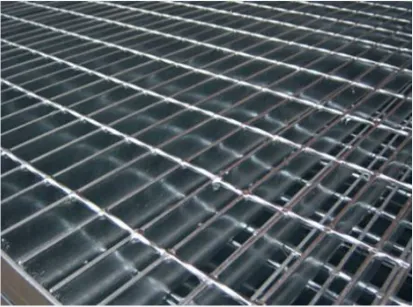

One of the standout benefits of wire mesh netting is its strength-to-weight ratio. Especially in construction, this means offering robust structural support without adding unnecessary weight. Whether utilized for reinforcing concrete in buildings or as fencing around properties, its presence ensures safety and structural integrity. Moreover, in agricultural settings, it serves as essential fencing to protect crops and livestock from predators, demonstrating resilience against environmental stressors such as harsh weather conditions.

In an industrial context, wire mesh netting finds its application in filtration and separation. Its capability to withstand high temperatures and chemical exposure makes it ideal for use in the petrochemical industry, where it filters impurities from liquids and gases. This mesh’s adaptability extends to conveyor belts in manufacturing processes, allowing for efficient handling of products through automated systems.

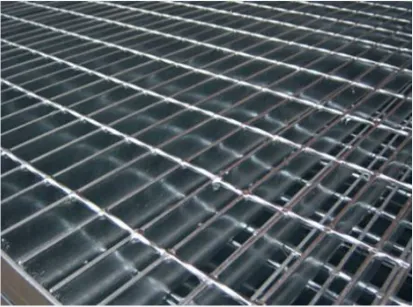

Wire mesh netting's application is not limited to practical or industrial uses; it also plays a significant role in architectural design. Architects and designers utilize mesh to create aesthetic facades, partitions, and unique decorative elements that add modern aesthetics to building designs. With its ability to reflect light and cast intriguing shadows, wire mesh can transform ordinary structures into architectural masterpieces.

wire mesh netting

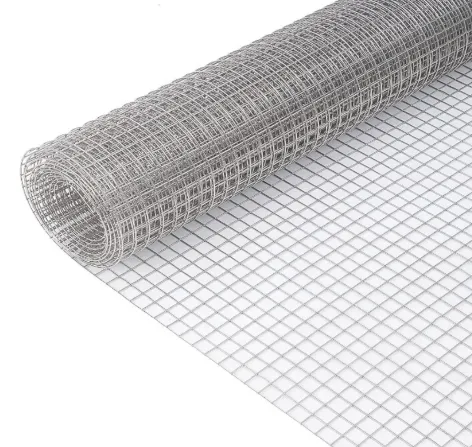

Environmental consciousness is another aspect where wire mesh netting proves advantageous. As the world gravitates towards sustainable solutions, the recyclability of materials like stainless steel has positioned wire mesh as an environmentally responsible choice. Its longevity and minimal need for replacement further underscore its sustainability benefits.

Several case studies highlight wire mesh netting’s effectiveness in problem-solving and innovation. In one instance, a coastal community employed galvanized wire mesh as erosion control barriers, successfully mitigating shoreline erosion while fostering local biodiversity. Such examples underscore the authoritative role that wire mesh can assume in creative problem-solving scenarios, validated through empirical evidence and user testimonials.

Collaborating with certified and reputable manufacturers ensures that customers receive high-quality wire mesh netting that adheres to international standards and specifications. This is paramount because the mesh's performance directly correlates to the precision of its manufacture. Procurement from experts assures businesses and consumers not just of product excellence but also compliance with stringent safety and sustainability regulations.

Investing in wire mesh netting encompasses more than simply selecting a material; it involves understanding its comprehensive benefits, matching its capabilities with specific requirements, and recognizing its potential in diverse applications. Industry testimonials consistently affirm wire mesh netting’s role as a reliable, adaptable, and cost-effective solution.

In conclusion, wire mesh netting remains a linchpin across varying domains, combining an impeccable blend of strength, durability, and versatility. Its applications, proven by years of reliable service and innovation, make it an essential commodity that meets the modern demands of industry, commerce, and design. Advocating for high-quality standards and sustainable practices, wire mesh netting is poised to continue its legacy as a fundamental material.