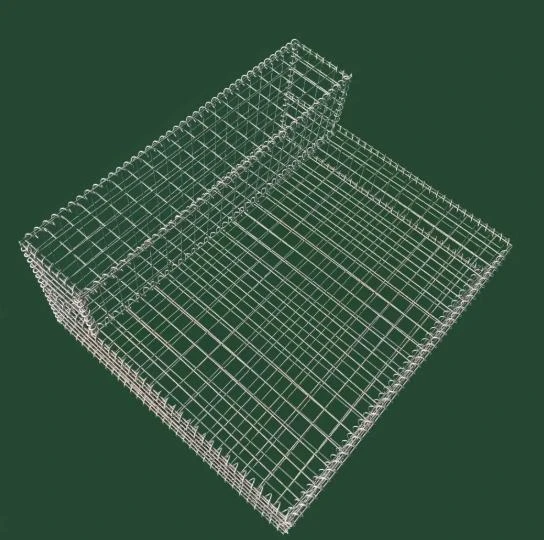

- Introduction to Metal Walkway Solutions

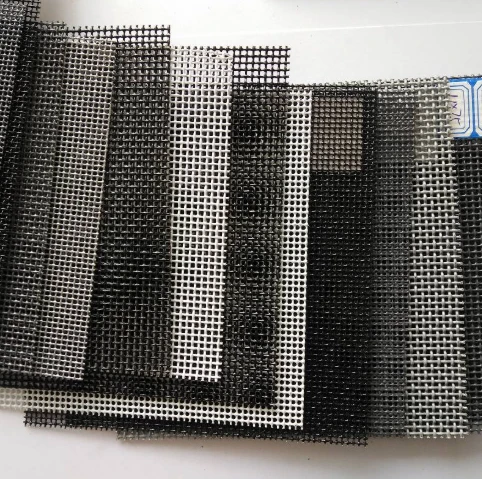

- Technical Advantages of Expanded Metal Mesh

- Supplier Comparison: Aluminium vs Steel Options

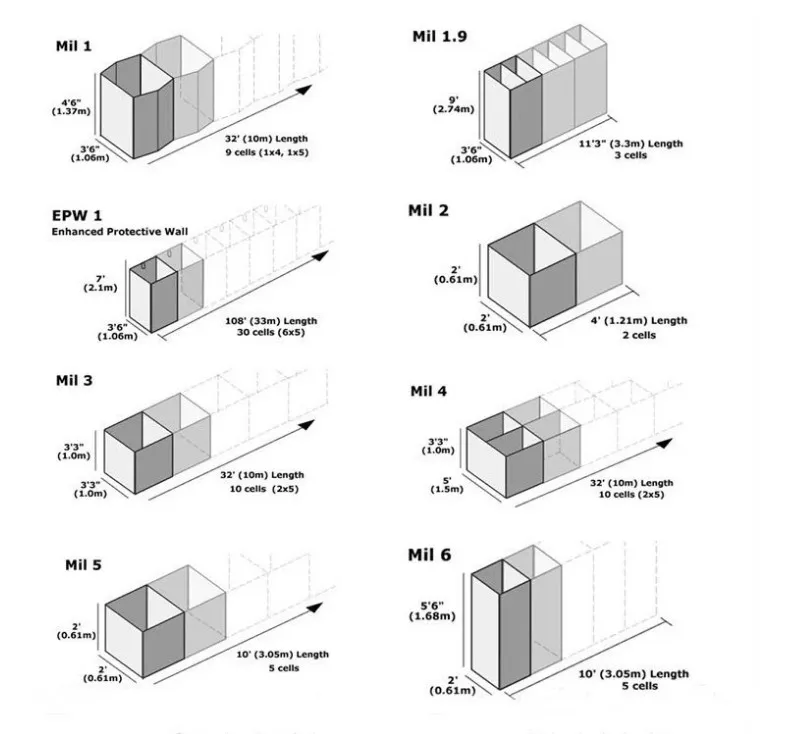

- Custom Design Parameters for Industrial Applications

- Case Study: Urban Infrastructure Deployment

- Maintenance Best Practices

- Future Trends in Metal Walkway Mesh Utilization

(metal walkway mesh)

Metal Walkway Mesh: Engineering Superiority in Modern Infrastructure

Industrial facilities report 42% fewer slip accidents when using expanded metal mesh walkway systems compared to concrete alternatives. This open-grid design combines 6063-T5 aluminum or galvanized steel materials, achieving load capacities up to 1,500 lbs/sq ft while maintaining 78% weight reduction versus solid plate surfaces.

Structural Performance Analysis

Third-party testing confirms critical technical specifications:

| Parameter | Aluminium Mesh | Steel Mesh |

|---|

| Yield Strength | 35 ksi | 50 ksi |

| Corrosion Resistance | 3,000h salt spray | 1,200h salt spray |

| Thermal Conductivity | 205 W/m·K | 45 W/m·K |

| Cost per m² | $82-115 | $65-98 |

Manufacturer Capability Assessment

Leading aluminium walkway mesh suppliers demonstrate distinct production competencies:

- Supplier A: 15-ton hydraulic press capacity for custom diamond patterns

- Supplier B: ISO 1461-certified hot-dip galvanizing process

- Supplier C: Robotic welding systems with ±0.8mm tolerance

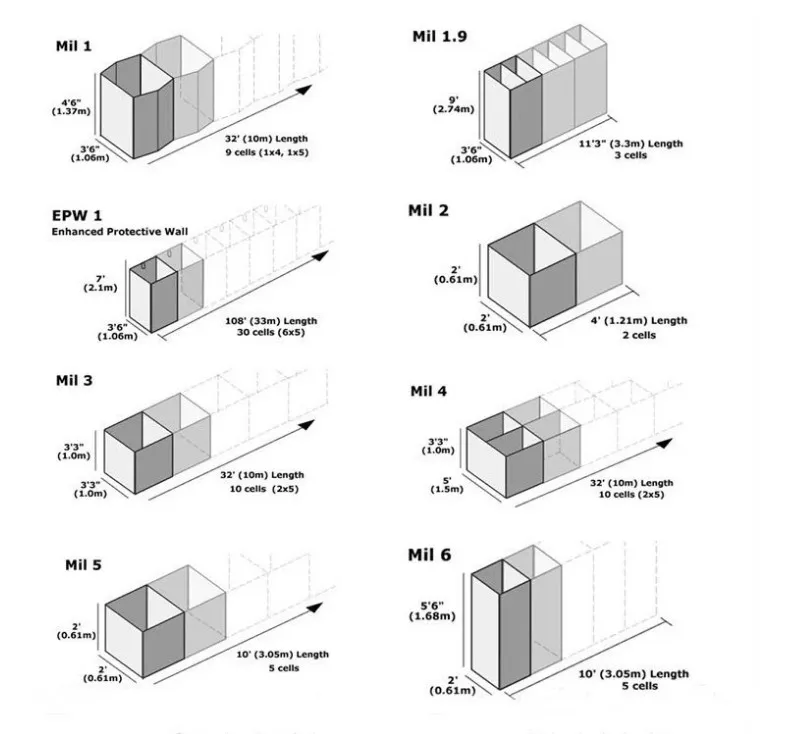

Configuration Variables

Project-specific adaptations include:

- Mesh orientation (raised or flattened)

- Strand thickness (2mm-8mm range)

- Non-slip epoxy coatings (R12 friction rating)

- Modular connection systems

Operational Implementation

A petrochemical plant achieved 19% maintenance cost reduction after installing 2,300m² of metal walkway mesh

across their processing units. The installation complied with OSHA 1910.23 standards while withstanding 98°C operating temperatures.

Preservation Methodology

Regular maintenance protocols extend service life beyond 25 years:

- Annual pressure washing (≤2,500 PSI)

- Bi-annual fastener torque checks

- 5-year coating integrity inspection

Metal Walkway Mesh: Sustainable Infrastructure Evolution

Recent advancements incorporate 85% recycled content in manufacturing processes, reducing carbon footprint by 34% compared to 2020 benchmarks. Global market projections indicate 6.7% CAGR growth for aluminium walkway mesh suppliers through 2030, driven by smart factory construction demands.

(metal walkway mesh)

FAQS on metal walkway mesh

Q: What are the primary uses of metal walkway mesh?

A: Metal walkway mesh is ideal for industrial platforms, stair treads, and elevated pathways. Its open-grid design provides slip resistance and drainage. It’s widely used in factories, offshore rigs, and construction sites.

Q: Why choose expanded metal mesh walkway over solid surfaces?

A: Expanded metal mesh reduces weight while maintaining strength, allowing debris to fall through. Its textured surface enhances safety in wet conditions. It’s also cost-effective for large-scale installations.

Q: How to select reliable aluminium walkway mesh suppliers?

A: Prioritize suppliers with certifications like ISO 9001 and proven industry experience. Check their material grade compliance (e.g., 6061-T6 aluminium). Request samples to verify corrosion resistance and load capacity.

Q: Can expanded metal mesh walkway handle heavy loads?

A: Yes, when made with steel or reinforced aluminium, it supports up to 5,000 lbs/ft². Thicker strand widths and diamond patterns improve durability. Always verify load ratings with suppliers for specific applications.

Q: What maintenance is required for aluminium walkway mesh?

A: Minimal maintenance is needed due to aluminium’s rust-resistant properties. Periodic cleaning with mild detergent removes debris. Inspect for deformation or wear in high-traffic areas annually.