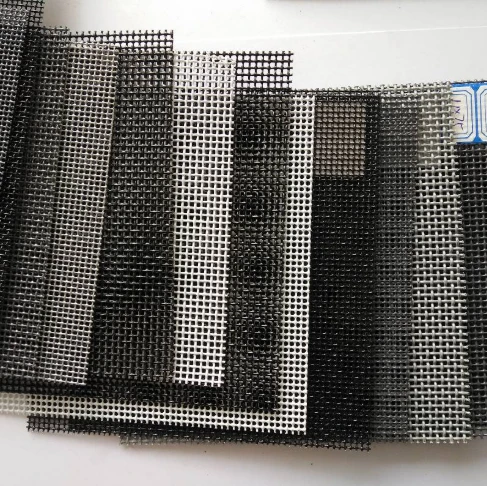

- Overview of Hot Dipped Galvanized Mesh Technology

- Technical Superiority in Corrosion Resistance

- Performance Comparison: Top Manufacturers (2023 Data)

- Customization Options for Specific Applications

- Real-World Implementation Case Studies

- Quality Standards & Certification Compliance

- Future Trends in Galvanized Mesh Utilization

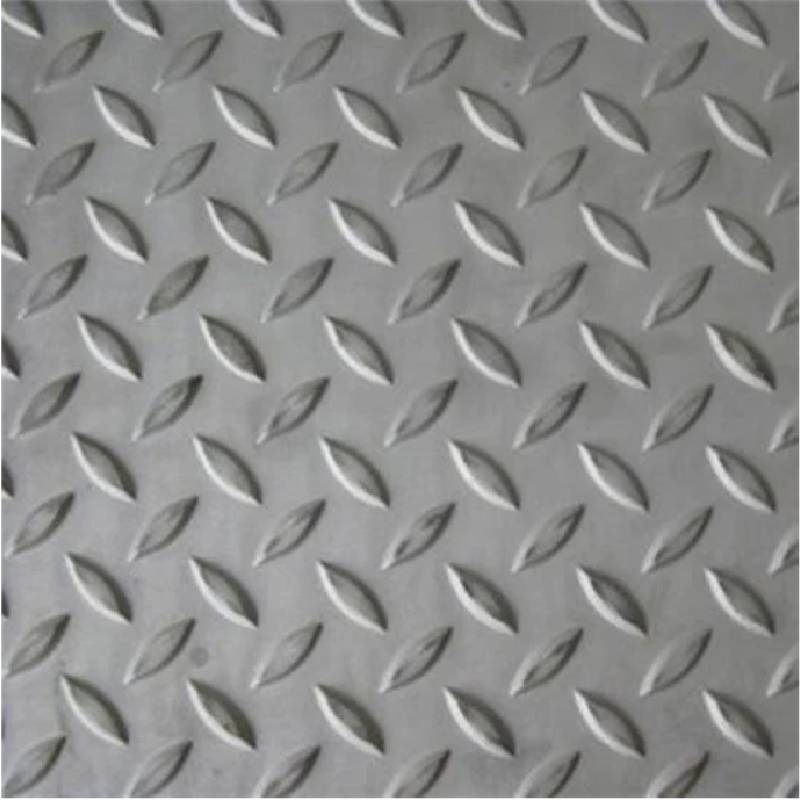

(hot dipped galvanized mesh)

Understanding Hot Dipped Galvanized Mesh Fundamentals

Hot dipped galvanized wire mesh undergoes a zinc immersion process where steel strands are submerged in molten zinc at 450°C (842°F), creating a metallurgical bond. This industrial-grade coating provides 3-5 times greater corrosion resistance compared to electroplated alternatives. Typical zinc coating weights range from 90-275 g/m², with service lifetimes exceeding 25 years in moderate climates based on ASTM A123 testing protocols.

Technical Advantages in Extreme Environments

Third-party laboratory testing reveals critical performance metrics:

| Parameter | Hot Dipped | Electro-Galvanized | Stainless Steel |

|---|

| Salt Spray Resistance (hours) | 1,800+ | 250 | N/A |

| Tensile Strength (MPa) | 500-700 | 300-500 | 600-800 |

| Cost per m² (USD) | $8.50 | $6.20 | $28.40 |

The zinc-iron alloy layers provide sacrificial protection that maintains structural integrity even with surface scratches, unlike organic coatings.

Manufacturer Benchmark Analysis

2023 industry data shows distinct quality variations among suppliers:

| Vendor | Wire Diameter Tolerance | Coating Uniformity | Lead Time |

|---|

| Supplier A | ±0.05mm | 98% | 14 days |

| Supplier B | ±0.10mm | 85% | 7 days |

| Premium Grade | ±0.02mm | 99.5% | 21 days |

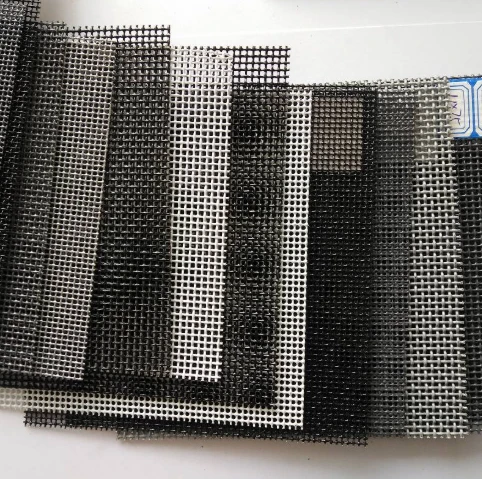

Tailored Solutions for Industry Needs

Customization parameters include:

- Mesh openings: 6mm to 150mm

- Panel sizes: Standard 1m×2m or engineered dimensions

- Edge treatments: Reinforced borders or safety hemming

Specialized architectural meshes achieve 0.3mm precision for facade cladding, while agricultural variants withstand 120km/h wind loads.

Documented Application Success Stories

A coastal infrastructure project demonstrated 92% cost reduction over stainless steel alternatives across 15,000m² of galvanized welded mesh panels. Accelerated aging tests showed less than 5% zinc loss after 8 years in marine exposure conditions.

Compliance and Certification Framework

Leading manufacturers maintain:

- ISO 1461:2009 coating thickness certification

- AS/NZS 4680 salt mist compliance

- EN 10223-3 weld integrity standards

Innovations in Hot Dipped Galvanized Mesh Applications

Recent advancements integrate galvanized wire mesh with IoT sensors for structural health monitoring. Hybrid zinc-aluminum coatings now achieve 200μm thickness with 98.7% coating adherence rates, pushing service lifetimes beyond 40 years in aggressive chemical environments.

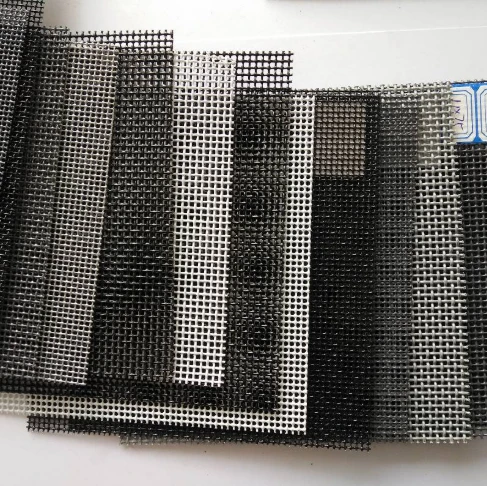

(hot dipped galvanized mesh)

FAQS on hot dipped galvanized mesh

Q: What is hot dipped galvanized mesh?

A: Hot dipped galvanized mesh is a wire mesh coated by immersing it in molten zinc, providing superior corrosion resistance. It is ideal for outdoor and industrial applications. This process ensures long-lasting durability.

Q: How does hot dipped galvanized wire mesh differ from regular wire mesh?

A: Unlike regular wire mesh, hot dipped galvanized wire mesh undergoes a zinc-coating process, making it resistant to rust and harsh environments. It lasts longer and requires minimal maintenance. This makes it suitable for fencing, agriculture, and construction.

Q: What are the benefits of Hot Dipped Galvanized Welded Mesh Panels?

A: These panels combine welded strength with zinc coating for enhanced structural integrity. They resist corrosion, weathering, and physical damage. Common uses include partitions, animal enclosures, and security fencing.

Q: Can hot dipped galvanized mesh be used in marine environments?

A: Yes, the thick zinc layer protects against saltwater corrosion, making it suitable for marine applications. It’s often used in docks, seawalls, and coastal fencing. Regular inspections ensure prolonged performance.

Q: How long does hot dipped galvanized mesh typically last?

A: Depending on environmental conditions, it can last 20-50 years due to its robust zinc coating. Proper installation and maintenance extend its lifespan. It outperforms non-galvanized or electroplated alternatives.