The Versatility and Applications of Stainless Steel Welded Wire Mesh Panels

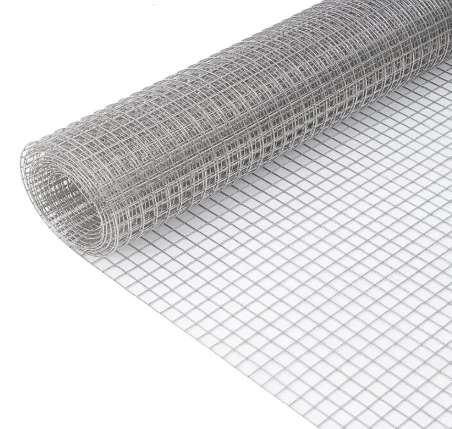

Stainless steel welded wire mesh panels are a remarkable and versatile product used in various industries. Made from high-quality stainless steel, these panels showcase an excellent combination of strength, durability, and resistance to corrosion. Their unique properties make them incredibly useful across a wide array of applications, from construction to agriculture, and even in architectural designs.

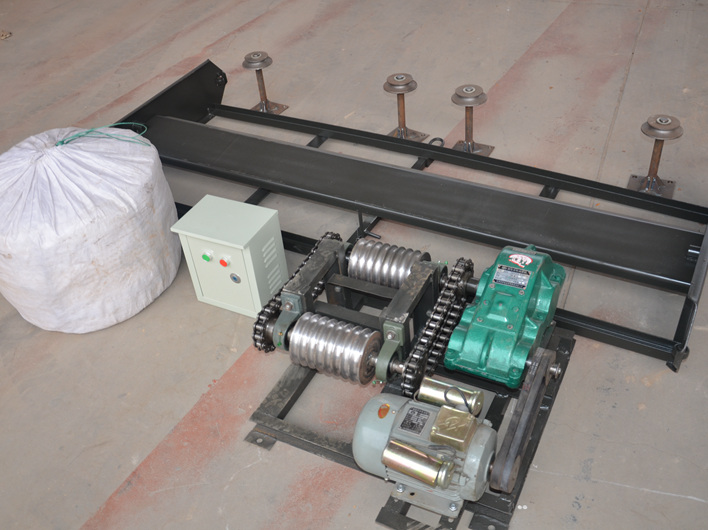

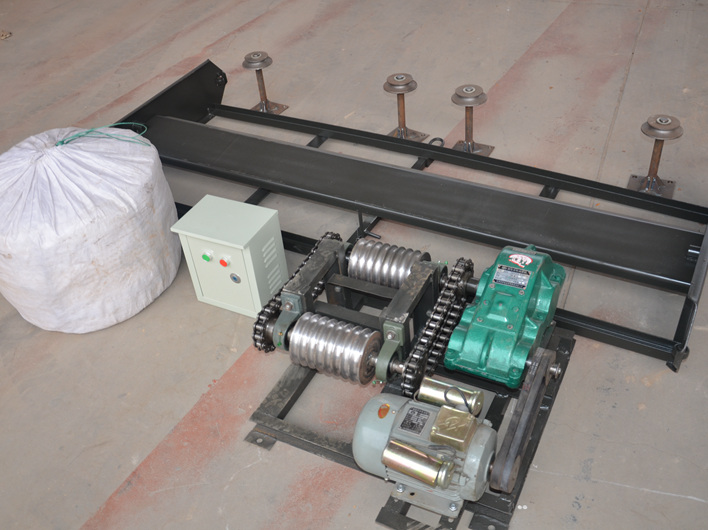

Composition and Manufacturing

Stainless steel welded wire mesh is produced by joining stainless steel wires at their intersections through a welding process, creating a robust and stable grid structure. The wire used in the manufacturing process can vary in gauge depending on the intended use of the mesh, and the panels can be fabricated in different sizes and shapes to meet specific project requirements. The most commonly used grades of stainless steel for these mesh panels include 304 and 316, with 316 offering superior resistance to corrosion, making it ideal for marine applications or areas with high salt exposure.

Key Features

1. Corrosion Resistance One of the greatest advantages of stainless steel is its inherent resistance to rust and corrosion, keeping the panels looking new over an extended period, even in harsh environments.

2. Durability Welded wire mesh panels are characterized by their strength, which allows them to withstand significant stress and load. This durability makes them ideal for fencing, security, and heavy-duty applications.

3. Versatile Applications Due to their versatile design, these panels can be used in various settings, including industrial, agricultural, and residential spaces.

4. Aesthetic Appeal Stainless steel finishes provide a sleek and modern look that enhances the aesthetics of any setting, making them popular for architectural projects.

5. Ease of Maintenance Unlike other materials that may require frequent maintenance, stainless steel welded wire mesh panels are easy to clean and maintain, ensuring long-lasting performance with minimal effort.

stainless steel welded wire mesh panels

Applications Across Industries

1. Construction In the construction industry, stainless steel welded wire mesh panels are often employed for reinforcing concrete slabs and other structural components. Their strength enhances the integrity of buildings and ensures safety.

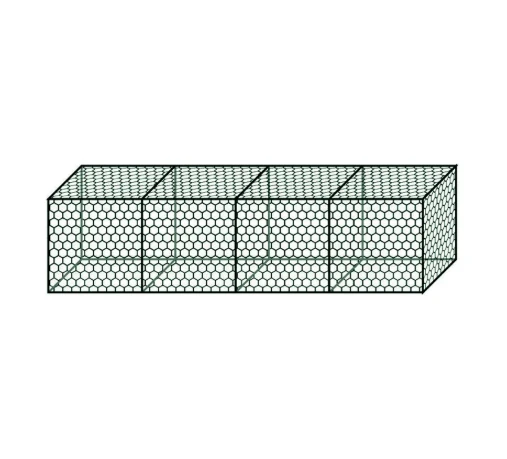

2. Agriculture Farmers utilize these panels for livestock enclosures, fencing, and crop protection. Their durability helps keep animals safe and secure while also protecting crops from pests.

3. Industrial Uses In factories and warehouses, welded wire mesh is frequently used for safety barriers, machinery guards, and storage solutions. Their ability to withstand heavy loads makes them ideal for these demanding environments.

4. Architecture and Design Modern architecture has embraced the use of stainless steel mesh panels for aesthetic and functional purposes. They can serve as decorative elements, sunshades, and even facades, providing both visual appeal and practicality.

5. Transportation Stainless steel welded wire mesh is also utilized in public transportation systems as safety barriers and partitions. Their visibility and strength contribute to safer travel experiences.

Conclusion

Stainless steel welded wire mesh panels are undeniably valuable across diverse industries due to their unique characteristics. Their combination of strength, aesthetics, and low maintenance makes them an optimal choice for many applications, from construction and agriculture to transportation and design. With advancements in manufacturing techniques and increased recognition of their benefits, these panels are sure to remain a staple material in modern construction and design.

As industries continue to evolve and seek sustainable and durable materials, the demand for stainless steel welded wire mesh panels is expected to rise. Their adaptability, coupled with a focus on long-term value and performance, positions them as a leading choice for future projects. Whether used in a utilitarian context or a design-centric approach, stainless steel welded wire mesh panels exemplify the intersection of functionality and elegance, making them an essential component of contemporary infrastructure.