- Understanding the Importance of Mesh Fencing in Modern Infrastructure

- Technical Advantages of High-Quality Wire Mesh Fencing

- Comparative Analysis of Leading Wire Mesh Manufacturers

- Customization Options for Industrial and Commercial Needs

- Case Studies: Successful Applications Across Industries

- Material Innovations and Durability Metrics

- Why Partnering with Expert Mesh Fencing Manufacturers Matters

(mesh fencing manufacturers)

Understanding the Importance of Mesh Fencing in Modern Infrastructure

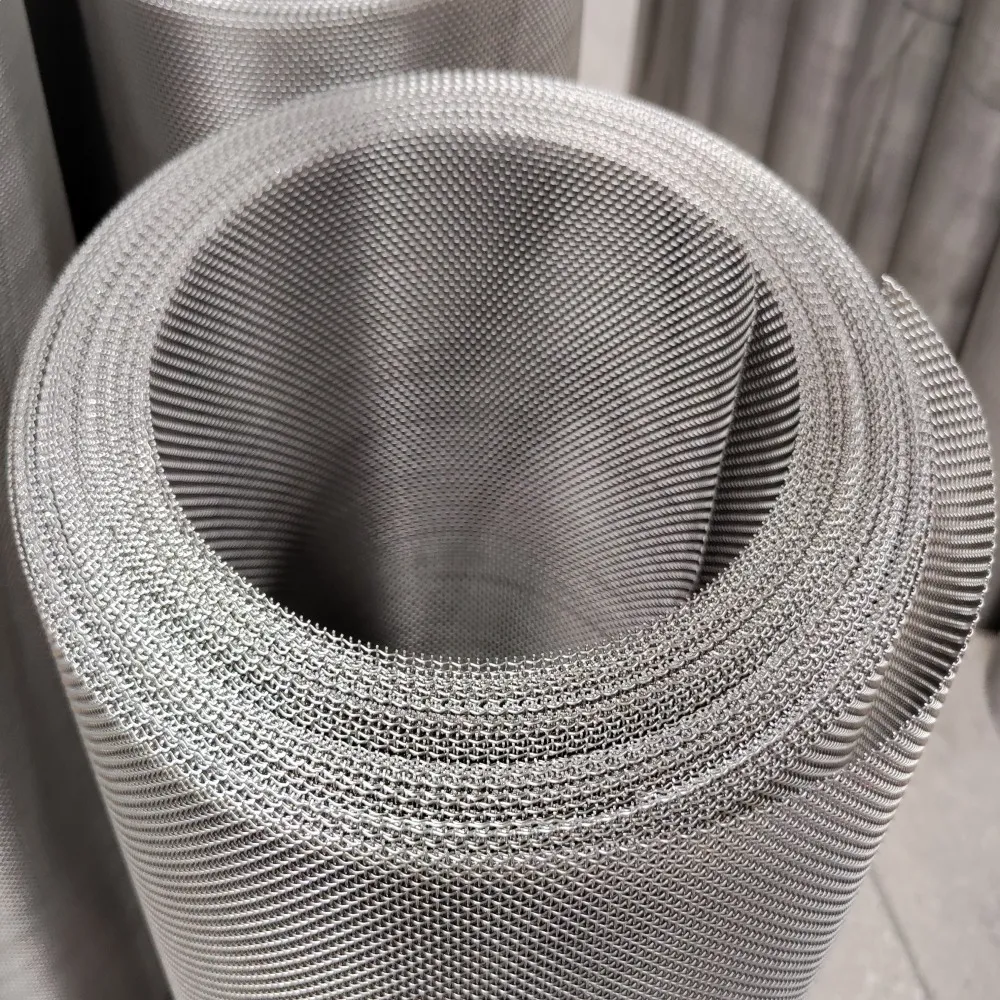

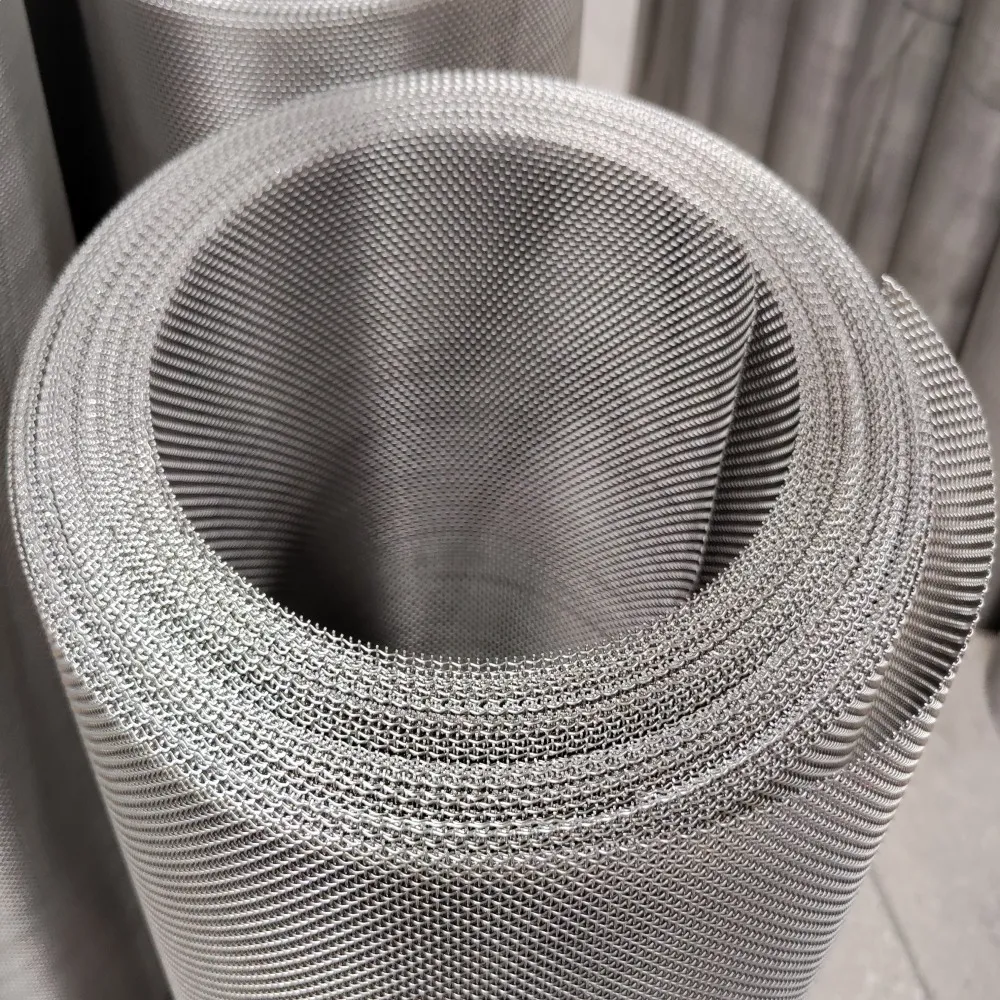

Mesh fencing has become a cornerstone in security and boundary solutions, with global demand growing at 6.2% CAGR since 2020. Industrial facilities, agricultural zones, and urban developments rely on wire mesh fencing manufacturers

to deliver robust, corrosion-resistant barriers. Unlike traditional options, welded or woven wire mesh provides superior tensile strength (ranging from 350-900 MPa) while maintaining visibility and airflow – critical for perimeter security without compromising design aesthetics.

Technical Advantages of High-Quality Wire Mesh Fencing

Premium wire mesh manufacturers employ galvanization processes that increase product lifespan by 40-60% compared to non-treated alternatives. Advanced PVC coating techniques reduce maintenance costs by 75% over a 15-year period. Key performance metrics include:

- Load resistance: Up to 12 kN/m for anti-climb configurations

- Mesh tolerance: ±1mm precision in automated production lines

- Environmental resilience: Withstanding temperatures from -40°C to 120°C

Comparative Analysis of Leading Wire Mesh Manufacturers

| Manufacturer |

Material Grade |

Panel Sizes (m) |

Coating Type |

Price/m² ($) |

| SteelGuard Solutions |

ASTM A856 |

2.4x3.0 |

Triple-layer PVC |

18.50 |

| FortressMesh Inc. |

EN 10223-5 |

2.0x2.5 |

Hot-dip galvanized |

15.80 |

| PrimeFence Technologies |

ISO 1461 |

3.0x4.0 |

Polyester powder |

21.30 |

Customization Options for Industrial and Commercial Needs

Top-tier mesh fencing manufacturers now offer 12 standard and 7 bespoke wire configurations. Variable parameters include:

- Mesh density: 50x50mm to 150x150mm

- Wire diameter: 3mm-8mm

- Color options: RAL catalog compliance

- Post configurations: Round, square, or embedded types

Case Studies: Successful Applications Across Industries

The 2023 expansion of Rotterdam Port utilized 18km of marine-grade mesh fencing from certified wire mesh manufacturers, demonstrating 98% corrosion resistance after 12-month salt spray tests. In agricultural sectors, a recent poultry farm project achieved 30% cost reduction through customized 75x75mm hexagonal mesh with integrated UV stabilization.

Material Innovations and Durability Metrics

Next-generation aluminum-zinc alloys now dominate 68% of premium mesh fencing production, offering 2.3x better oxidation resistance than traditional galvanized steel. Accelerated aging tests show:

- 0.12mm/year corrosion rate in coastal environments

- 95% structural integrity after 25 years

- Class A fire resistance ratings

Why Partnering with Expert Mesh Fencing Manufacturers Matters

Specialized mesh fencing manufacturers deliver 35% faster project turnaround through CAD-assisted design systems. Their technical teams typically reduce material waste by 22% through optimized cutting algorithms. For infrastructure projects exceeding 5,000m², partnering with ISO-certified wire mesh manufacturers ensures compliance with 23 international safety standards while maintaining cost-efficiency.

(mesh fencing manufacturers)

FAQS on mesh fencing manufacturers

Q: What factors should I consider when choosing wire mesh fencing manufacturers?

A: Prioritize manufacturers with proven expertise, material quality (e.g., galvanized steel), certifications, and customer reviews. Customization options and delivery timelines are also key considerations.

Q: How do mesh fencing manufacturers ensure durability in their products?

A: Reputable manufacturers use corrosion-resistant materials like stainless steel or PVC-coated wire. Advanced welding techniques and weather-resistant finishes further enhance longevity.

Q: Can wire mesh manufacturers create custom designs for specific projects?

A: Yes, most offer tailored solutions for mesh size, panel dimensions, and wire gauges. Provide project specifications to ensure the design meets functional and aesthetic requirements.

Q: What certifications should reliable wire mesh fencing manufacturers have?

A: Look for ISO 9001 for quality management, ASTM or EN standards compliance, and environmental certifications. These ensure adherence to industry benchmarks and sustainable practices.

Q: How do I compare pricing among mesh fencing manufacturers?

A: Request detailed quotes including material costs, production fees, and shipping. Evaluate value-added services like installation support or warranties to make informed decisions.