In an era increasingly focused on sustainability and eco-conscious design, industries are looking for materials that not only meet their functional needs but also contribute to environmental protection. One such material is woven wire mesh, a versatile and durable solution that offers significant advantages in terms of sustainability. Whether used in construction, filtration, agriculture, or security, woven wire mesh represents an eco-friendly choice that aligns with modern sustainability goals. This essay explores why woven wire mesh is an ideal material for a sustainable future, highlighting its recyclability, longevity, and energy-efficient production methods.

Woven Wire Mesh: Reducing Waste Over Time

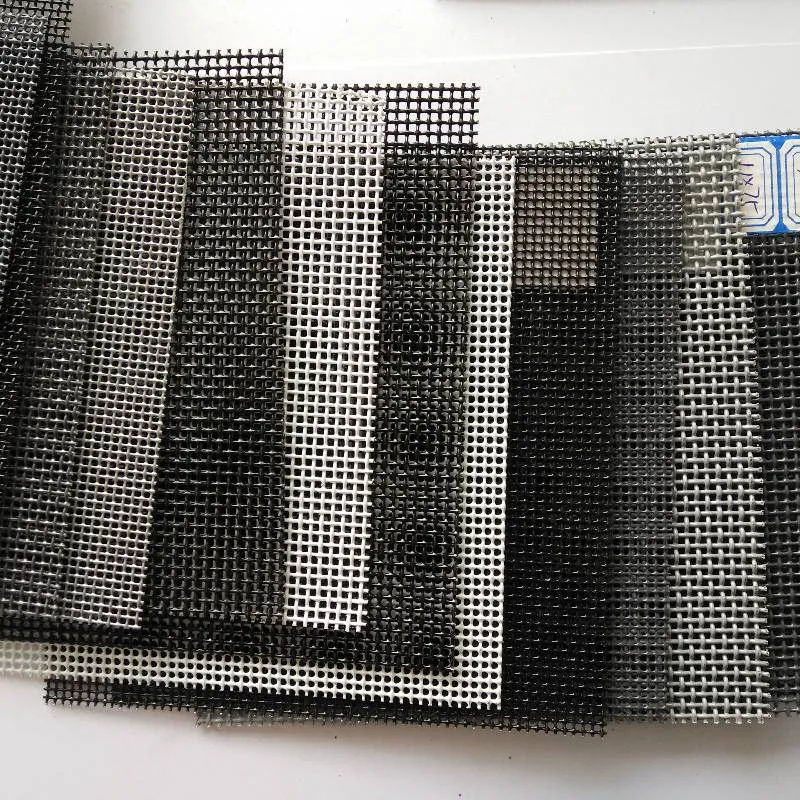

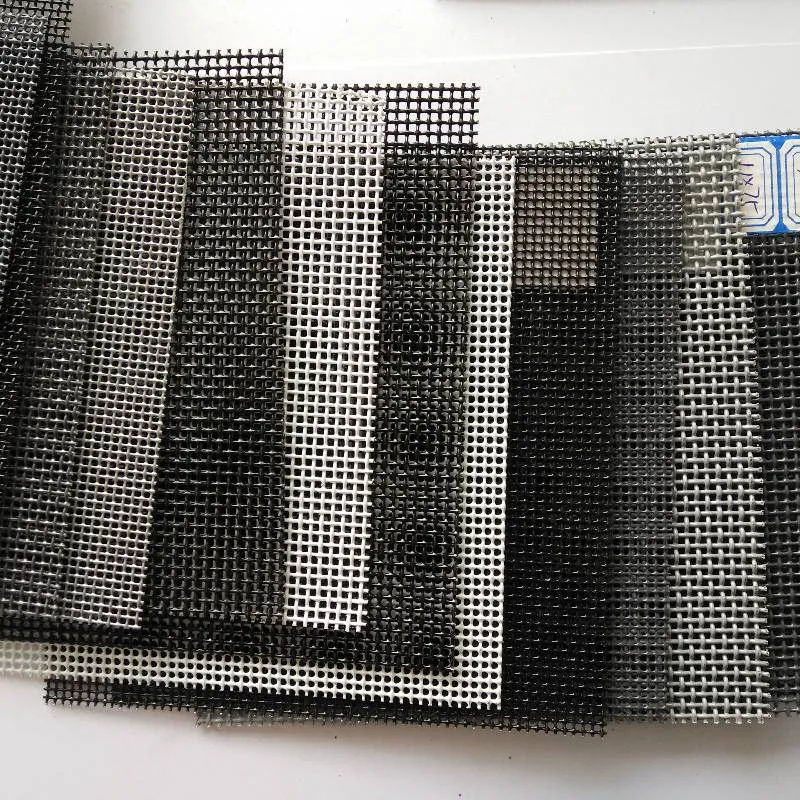

One of the primary reasons woven wire mesh is a sustainable choice is its exceptional durability. Unlike other materials that may degrade or wear out over time, woven wire screens are highly resistant to corrosion, abrasion, and wear. Made from stainless steel, galvanized steel, or other robust metals, woven wire mesh can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications. This longevity means that products made from woven wire mesh have a significantly longer life span than alternatives, which reduces the need for frequent replacements and minimizes waste.

Woven Wire Mesh: Closing the Loop

Another compelling reason that woven wire mesh stands out as a sustainable choice is its recyclability. Woven wire mesh products are typically made from metals such as stainless steel or galvanized steel, both of which are highly recyclable. When a woven wire screen has reached the end of its useful life, it can be melted down and repurposed into new products without compromising the material’s quality. This "closed-loop" recycling system reduces the demand for virgin materials, conserving natural resources and cutting down on energy consumption associated with the production of new materials.

Low Environmental Impact Production of Woven Wire Mesh

The production of woven wire mesh also has a relatively low environmental impact compared to many other materials. The manufacturing process typically involves weaving individual wires together to form a mesh, which requires fewer resources than producing other types of mesh or screen materials. Woven wire is produced using simple and efficient techniques, and many manufacturers use sustainable practices to further minimize energy consumption and waste during production.

Additionally, the use of woven wire in construction and filtration systems can reduce the overall environmental impact of these industries. For example, in filtration applications, woven wire mesh screens provide an effective and long-lasting solution for separating particles from water or air, leading to better resource management and cleaner environmental practices. This not only ensures better filtration but also reduces the amount of waste generated by frequent replacements of less durable materials.

Versatility in Sustainable Applications of Woven Wire Mesh

One of the defining features of woven mesh is its versatility across a wide range of industries, all of which are increasingly emphasizing sustainability. In the agricultural sector, woven wire mesh is used in fencing, crop protection, and even livestock management. Its ability to resist corrosion and withstand the elements means it can be used to create durable enclosures that protect both crops and animals without the need for frequent maintenance or replacement.

Woven wire mesh represents a sustainable material for the future due to its durability, recyclability, and versatility. By offering long-lasting performance, reducing the need for frequent replacements, and enabling efficient recycling processes, it contributes to resource conservation and waste reduction. Its widespread applications, from agriculture to construction, further demonstrate its importance in building a more sustainable world. As industries continue to prioritize eco-friendly solutions, the role of woven wire mesh screen in promoting sustainability will only grow, cementing its place as a key material in environmentally-conscious design and innovation.