The versatility and functionality of expanded metal mesh have made it a staple in various industries, ranging from architecture to engineering.

One of the critical considerations in using expanded metal mesh is understanding its thickness. Here, the importance of expanded metal mesh thickness will be explored, providing insights based on real-world experience and professional expertise.

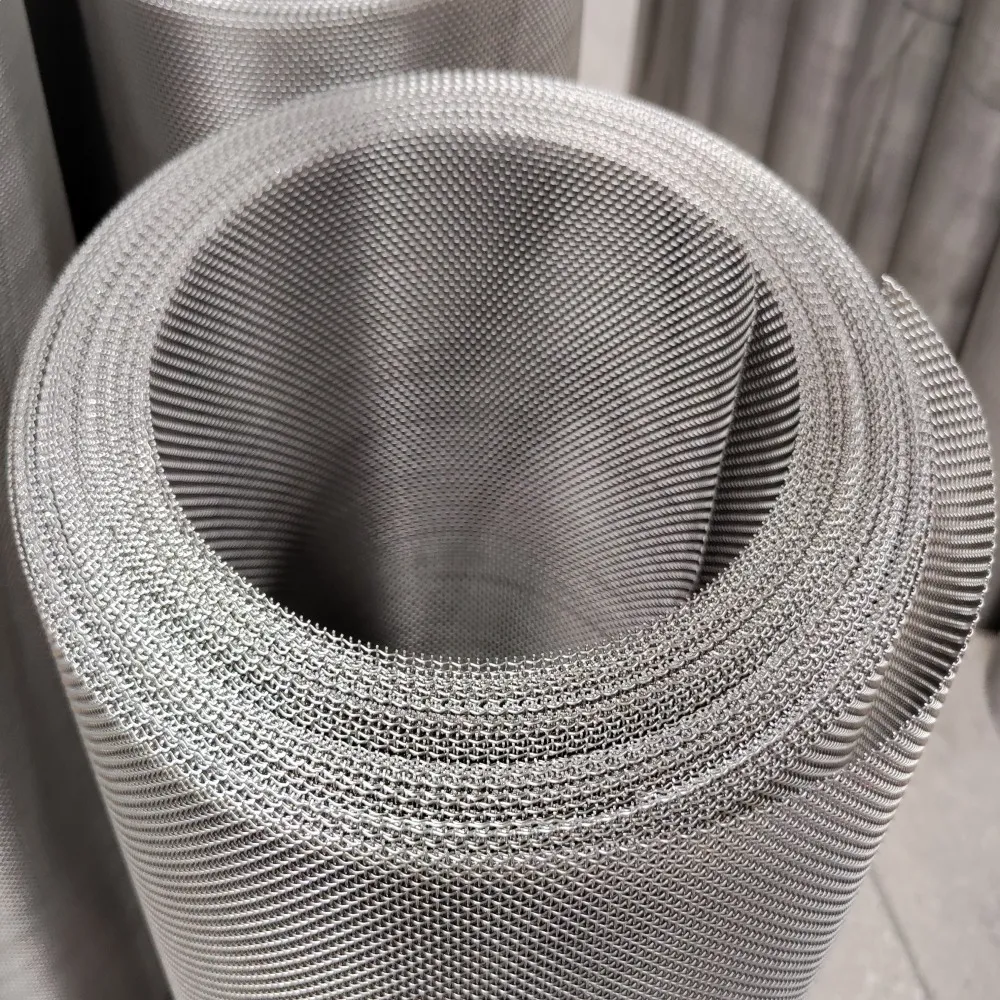

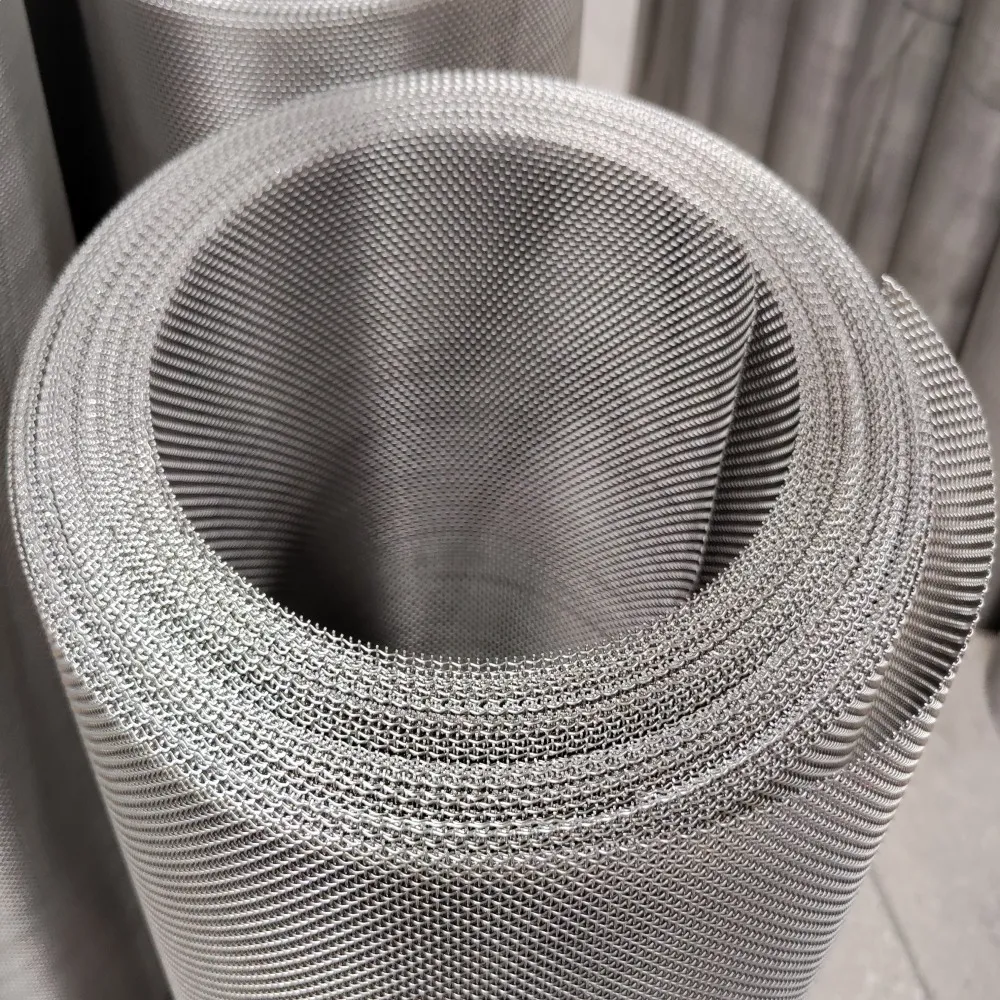

Expanded metal mesh is manufactured by cutting and stretching a solid sheet of metal, which results in a mesh with diamond-shaped openings. This process not only produces a material that is stronger and more rigid than its original form, but also one that is remarkably lightweight. The thickness of the expanded metal mesh plays a crucial role in defining these properties, giving rise to varying applications depending on the thickness selected.

A common misconception is that the thickness of expanded metal mesh is identical to that of the original sheet metal. However, as the metal is expanded, its overall thickness can change. Accurate understanding and specification of the thickness are critical for successful application and performance. Typically, the thickness of expanded metal mesh is measured at the strand, known as strand thickness, which is different from the gauge or the thickness of the base sheet before expansion.

For architectural applications, expanded metal mesh with different thickness levels can transform into stunning façades, sunscreens, or even interior design elements. Thicker meshes provide enhanced structural integrity and are often used when the material needs to withstand significant weights or pressure. In contrast, thinner meshes are suitable for applications where weight-saving is a priority, such as in decorative panels or elements that do not support heavy loads.

In the field of engineering, especially in environments with harsh conditions such as oil rigs or chemical plants, the durability provided by a specific thickness of expanded metal mesh is crucial. Thicker meshes are typically preferable in these settings as they offer more resistance to wear and tear, thus ensuring longevity and reducing maintenance costs. Moreover, their rigidity can add to the overall stability of the infrastructure.

expanded metal mesh thickness

Another advantage of selecting the appropriate thickness is the balance between visibility and protection. Thicker meshes may offer better security and privacy, which is desirable in certain applications like fencing or enclosures, where the barrier needs to be unobtrusive yet effective. Thinner meshes, however, provide more visibility and are often used in items where aesthetic visibility is more critical than security.

Expert guidelines emphasize the importance of consulting with manufacturers/designers when selecting the thickness of expanded metal mesh. These professionals can provide valuable insights based on specific project requirements, enabling the best match between material and application. Additionally, their expertise ensures compliance with industry standards and safety regulations, thereby bolstering the credibility and trustworthiness of the project outcomes.

The authoritativeness of this discussion on expanded metal mesh thickness is supported by countless projects and applications across the globe. Case studies from bridges, stadiums, to contemporary homes highlight the importance of selecting the right thickness to harness the full potential of expanded metal mesh. These projects are testaments to the mesh's capability in providing both functional and aesthetic solutions, driven by informed thickness choices.

In conclusion, the selection of expanded metal mesh thickness should be a calculated decision based on specific application needs, environmental conditions, and desired outcomes. With expert guidance, one can leverage the full potential of expanded metal mesh, ensuring robust, reliable, and visually appealing results. The next time you consider using expanded metal mesh, remember that its thickness is not just a number—it is a defining factor in achieving the best possible performance for your project.