Introduction to PVC Coated Welded Mesh Panels: Market Dynamics and Evolutionary Trends

In the intricate landscape of modern infrastructure and security solutions, the PVC Coated Welded Mesh Panel stands as a cornerstone of durability, aesthetic appeal, and cost-effectiveness. This engineered material, meticulously designed through a rigorous manufacturing process, has transcended its initial applications to become indispensable across a myriad of sectors, including perimeter security, agricultural enclosures, industrial partitioning, and architectural embellishments. The global market for PVC coated mesh products is currently experiencing robust growth, driven by escalating demands for secure and sustainable fencing solutions, particularly in burgeoning urban centers and critical infrastructure projects worldwide. Recent market analyses from reputable industry intelligence firms indicate a compound annual growth rate (CAGR) exceeding 6% for the overall coated mesh market, with PVC variants commanding a significant share due to their superior corrosion resistance and versatility. Key market drivers include the increasing need for enhanced security measures in residential, commercial, and governmental properties, the expansion of agricultural and aquaculture industries requiring reliable containment solutions, and the ongoing development of public parks and recreational facilities where both safety and visual integration are paramount. Furthermore, environmental considerations are influencing product development, with a growing emphasis on lead-free PVC formulations and improved recycling processes for end-of-life materials, reflecting a broader industry trend towards circular economy principles. This commitment to sustainability not only aligns with global regulatory frameworks but also appeals to corporate clients focused on their environmental, social, and governance (ESG) objectives. The evolution of coating technologies has also enabled the production of panels with enhanced UV stability, preventing color fading and degradation under prolonged sun exposure, thereby extending the product's service life and maintaining its aesthetic integrity. As urban sprawl continues and infrastructure development intensifies, the demand for resilient, low-maintenance, and visually appealing security and containment solutions will undoubtedly propel the PVC Coated Welded Mesh Panel to even greater prominence, solidifying its position as a vital component in modern construction and protection strategies. Manufacturers are continuously innovating, exploring new polymer compounds for coatings that offer even greater adhesion, flexibility, and resistance to extreme temperatures, further broadening the applicability of these panels in diverse climatic conditions and demanding operational environments.

Beyond traditional applications, the utility of the PVC Coated Welded Mesh Panel is expanding into niche markets such as animal husbandry for resilient enclosures, aquaculture for sturdy fish farm cages, and even in specialized architectural facades where semi-transparent, durable barriers are required. The adaptability of these panels, particularly concerning customizable mesh sizes and wire diameters, enables architects and engineers to specify solutions that perfectly balance security requirements with aesthetic objectives. The inherent resistance of PVC to a wide range of chemicals, including acids, alkalis, and salts, makes these panels particularly suitable for installations in coastal regions or industrial environments where conventional metallic fences would rapidly corrode. This chemical inertness, coupled with the robust mechanical properties of the underlying steel wire, results in a product that delivers exceptional performance over extended periods, minimizing replacement costs and maintenance burdens for end-users. Industry trends also highlight an increasing preference for modular and pre-fabricated fencing systems that utilize PVC Coated Welded Mesh Panel components, streamlining installation processes and reducing on-site labor costs. This modularity allows for quicker deployment and greater flexibility in design, catering to temporary installations or permanent structures with equal efficiency. Furthermore, advanced manufacturing techniques now permit greater control over the bonding process between the PVC layer and the galvanized steel wire, ensuring a seamless, highly adhesive coating that resists peeling, cracking, and chipping even under mechanical stress or significant temperature fluctuations. This technological advancement significantly enhances the product's longevity and performance in challenging environmental conditions. The ongoing research and development efforts within the industry are focused on creating more eco-friendly PVC alternatives, exploring bio-based plasticizers, and improving the overall life cycle assessment of these products, underscoring a commitment to sustainable manufacturing practices while maintaining the high performance standards that clients expect from such critical infrastructure components.

Technical Parameters and Core Specifications of PVC Coated Welded Mesh Panels

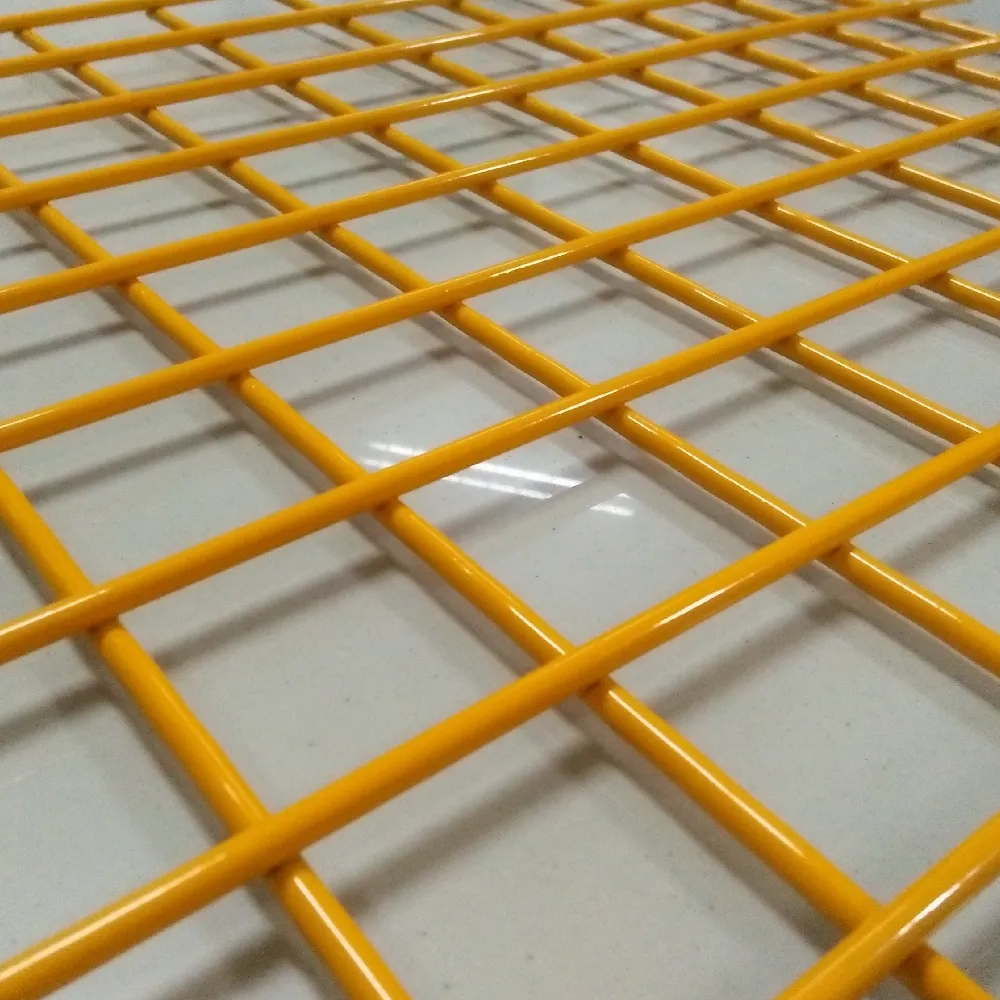

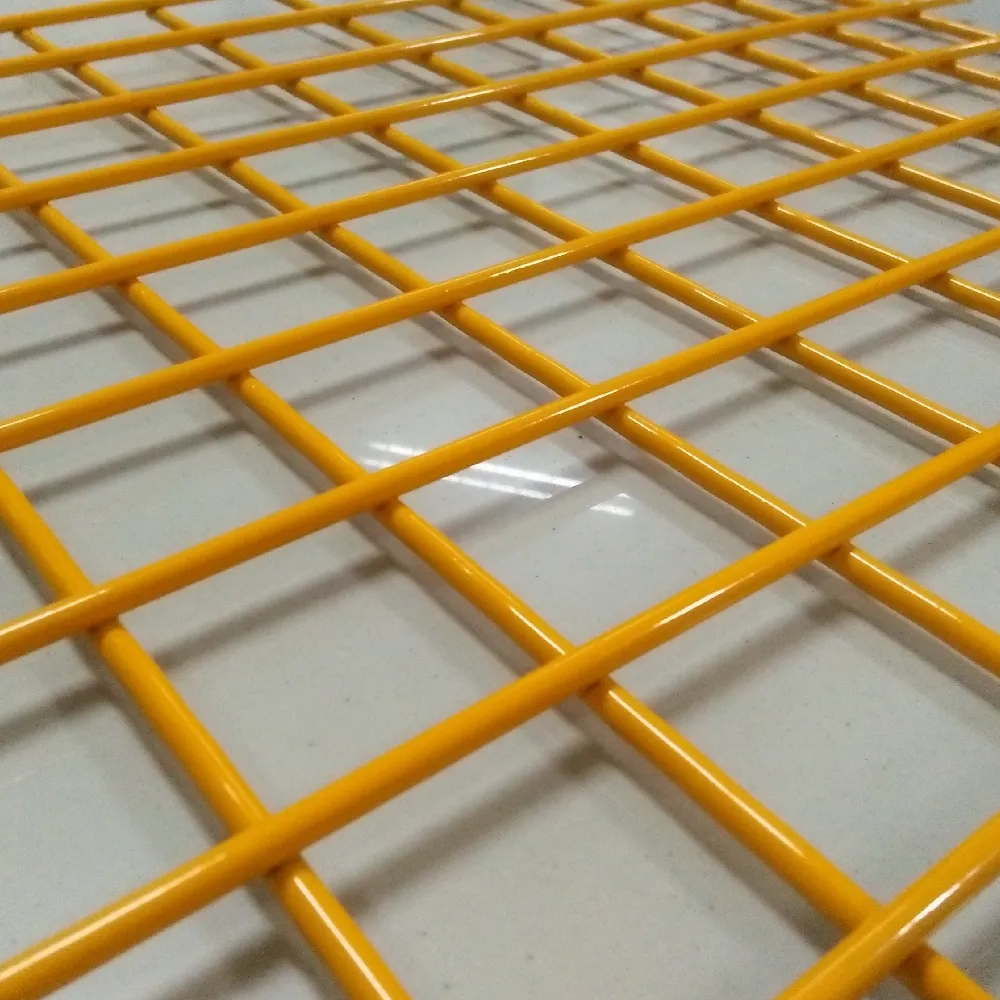

Understanding the comprehensive technical specifications of a PVC Coated Welded Mesh Panel is paramount for engineering professionals and procurement specialists seeking optimal performance and longevity in their projects. At its core, this product is an integration of high-strength steel wire, galvanized for initial corrosion protection, and then meticulously coated with a layer of polyvinyl chloride (PVC). The foundational material, typically low-carbon steel wire, must adhere to stringent metallurgical standards, often specified by ASTM A641 or BS EN 10218, ensuring a minimum tensile strength of 500-600 MPa and a yield strength that guarantees structural integrity under load. The galvanization process, usually hot-dip galvanizing per ASTM A123 or BS EN ISO 1461, provides a sacrificial zinc layer, offering cathodic protection against rust and extending the lifespan of the steel substrate significantly. This zinc coating typically ranges from 40-60 g/m², forming a robust barrier before the final PVC application. The subsequent PVC coating is a critical determinant of the panel's long-term performance, offering unparalleled resistance to a wide spectrum of environmental aggressors including ultraviolet (UV) radiation, chemical exposure (e.g., salts, mild acids, alkalis), and extreme temperature fluctuations from -30°C to +70°C. The thickness of the PVC layer is a crucial parameter, commonly ranging from 0.4mm to 1.0mm (total diameter increase of 0.8mm to 2.0mm), directly influencing the panel's anti-corrosion efficacy and its ability to withstand abrasion and impact. Thicker coatings provide enhanced protection in highly corrosive or abrasive environments.

The mesh apertures, or grid sizes, are standardized to meet various application requirements, with common dimensions including 50x50mm, 50x100mm, 75x75mm, and 100x100mm, alongside customized configurations. These dimensions directly impact visibility, security level, and material economy. Wire diameters, post-PVC coating, typically range from 2.5mm to 6.0mm, influencing the panel's rigidity, strength, and overall weight. For instance, a 50x50mm mesh with a 4.0mm coated wire diameter provides substantial security and rigidity suitable for high-security fencing, while a larger mesh with a thinner wire might be preferred for decorative or lighter-duty applications. Key performance indicators (KPIs) for PVC coated panels include adhesion strength of the PVC to the galvanized wire, which is vital to prevent delamination and premature failure. This is often tested via a "pull-off" or "knife-peel" test, ensuring the bond can withstand environmental stresses. Furthermore, UV resistance is quantified by accelerated weathering tests (e.g., ASTM G154 or ISO 4892), simulating years of sun exposure to predict long-term color stability and material integrity. Salt spray testing (e.g., ASTM B117 or ISO 9227) is also crucial, assessing the panel's resistance to corrosive saline environments, a critical factor for coastal installations.

Representative Technical Parameters Table: PVC Coated Welded Mesh Panel

| Parameter |

Typical Range/Value |

Relevant Standard |

| Core Wire Material |

Low Carbon Steel (Q195/Q235 equivalent) |

ASTM A853, BS EN 10218-2 |

| Pre-Coating Finish |

Electro Galvanized (10-20 g/m²) or Hot-Dip Galvanized (40-60 g/m²) |

ASTM A641, BS EN ISO 1461 |

| Wire Diameter (Core) |

2.0mm - 5.0mm |

Tolerance per BS EN 10218-2 |

| Wire Diameter (Coated) |

2.5mm - 6.0mm (approx. +0.5mm to +1.0mm per side) |

Internal QA, Customer Spec |

| PVC Coating Thickness |

0.4mm - 1.0mm (radial) |

Internal QA, Customer Spec |

| Mesh Opening (Aperture) |

50x50mm, 50x100mm, 75x75mm, 75x150mm, 100x100mm etc. |

ISO 9044, Customer Spec |

| Panel Width |

0.5m - 3.0m |

Customer Spec |

| Panel Length |

1.0m - 6.0m |

Customer Spec |

| Tensile Strength (Coated Wire) |

Typically >450 MPa |

ASTM A853, BS EN 10218-2 |

| Corrosion Resistance |

>500 hours Salt Spray (no red rust) |

ASTM B117, ISO 9227 |

| UV Resistance |

Excellent (Minimal color fade/degradation) |

ASTM G154, ISO 4892 |

| Operating Temperature Range |

-30°C to +70°C |

Internal QA, Material Datasheet |

| Color Options |

RAL 6005 (Dark Green), RAL 9005 (Black), RAL 7016 (Anthracite Grey), Custom |

RAL K7 Color Chart |

The detailed parameters outlined above allow for precise engineering and specification, ensuring that the selected PVC Coated Welded Mesh Panel perfectly aligns with project-specific requirements, whether for high-security installations demanding robust wire diameters and small mesh apertures, or for aesthetic fencing where color stability and UV resistance are paramount. The meticulous control over these technical aspects during manufacturing is what differentiates a high-quality product from inferior alternatives, guaranteeing a long service life and exceptional performance in diverse environmental conditions.

The Meticulous Craft: Manufacturing Process of PVC Coated Welded Mesh Panels

The production of a high-quality PVC Coated Welded Mesh Panel is a multi-stage, precision-engineered process that begins with the selection of premium raw materials and culminates in a durable, aesthetically pleasing, and highly functional product. This sophisticated manufacturing sequence ensures the optimal adhesion of the PVC layer to the galvanized steel core, guaranteeing exceptional longevity and performance in diverse environments. The initial step involves the precise drawing of high-quality low-carbon steel rods into specific wire diameters. This wire drawing process, typically performed on multi-stage drawing machines, reduces the wire's diameter incrementally while enhancing its tensile strength and ductility, preparing it for the subsequent welding phase. Following drawing, the steel wire undergoes a meticulous cleaning process, often involving acid pickling and rinsing, to remove any impurities, scale, or residual lubricants that could compromise the adhesion of the galvanization or PVC coating.

The second crucial stage is the galvanization of the steel wire. This is predominantly achieved through hot-dip galvanizing, a process where the cleaned steel wire is immersed in a molten zinc bath at approximately 450°C. This creates a metallurgically bonded zinc coating that serves as the primary corrosion barrier, offering cathodic protection to the underlying steel. The thickness and uniformity of this zinc layer are critical and are continuously monitored to meet standards such as ASTM A123 or BS EN ISO 1461, typically ranging from 40-60 g/m². For certain applications, electro-galvanization might be used, offering a thinner but more uniform zinc layer. After galvanization, the wires are fed into automated welding machines. These advanced machines utilize resistance welding technology to precisely fuse the horizontal and vertical wires at their intersections, forming a consistent and strong mesh panel. The welding points are critical for the panel’s structural integrity, and automated quality control systems often employ vision inspection to identify and rectify any weak welds or misaligned wires, ensuring uniform mesh aperture and panel dimensions.

The culmination of the process is the PVC coating. Before coating, the galvanized mesh panels undergo another thorough cleaning and pre-treatment phase, which often includes a chromate conversion coating or an organic primer. This step is vital for promoting exceptional adhesion between the PVC and the galvanized surface, preventing delamination over time. There are primarily two methods for applying the PVC coating:

-

Fluidized Bed Dipping: In this method, the pre-heated mesh panel is immersed into a bed of finely powdered PVC resin, which is fluidized by air. The heat from the panel causes the PVC powder to melt and adhere uniformly to the wire surface. This method typically results in a thicker, more durable coating, known for its excellent coverage and adhesion, particularly at weld points.

-

Extrusion Coating: This technique involves extruding molten PVC directly onto the wire as it passes through a die. This method allows for precise control over coating thickness and is often used for continuous wire coating before welding, or for coating individual wires that are then welded. While highly efficient, it requires careful control to ensure complete encapsulation of the weld points.

After the PVC application, the panels pass through a curing oven where the PVC polymerizes and fuses into a continuous, smooth, and resilient layer. This curing step is meticulously controlled to ensure optimal coating properties, including hardness, flexibility, and UV resistance. Throughout the entire manufacturing process, rigorous quality control checkpoints are implemented. These include visual inspections for defects, dimensional checks for mesh size and panel dimensions, adhesion tests for the PVC coating (e.g., knife peel test, cross-hatch test), salt spray tests (ASTM B117) to verify corrosion resistance, and UV exposure tests (ASTM G154) to ensure long-term color stability and material integrity. Adherence to international standards such as ISO 9001 for quality management systems is paramount, ensuring traceability and consistent product quality from raw material to finished PVC Coated Welded Mesh Panel. The combination of high-grade materials and advanced manufacturing techniques yields a product with a projected service life often exceeding 15-20 years, even in challenging outdoor environments, minimizing the total cost of ownership for end-users by reducing the need for frequent replacements and maintenance. This meticulous process underscores the technical expertise required to produce a product that excels in both protective functionality and visual appeal.

Diverse Application Scenarios and Intrinsic Advantages of PVC Coated Welded Mesh Panels

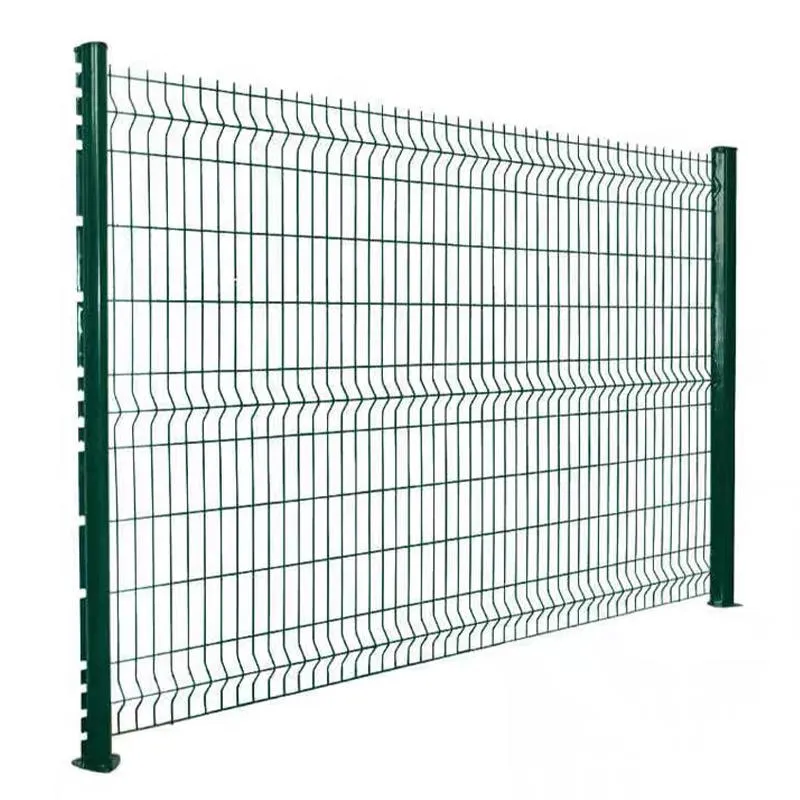

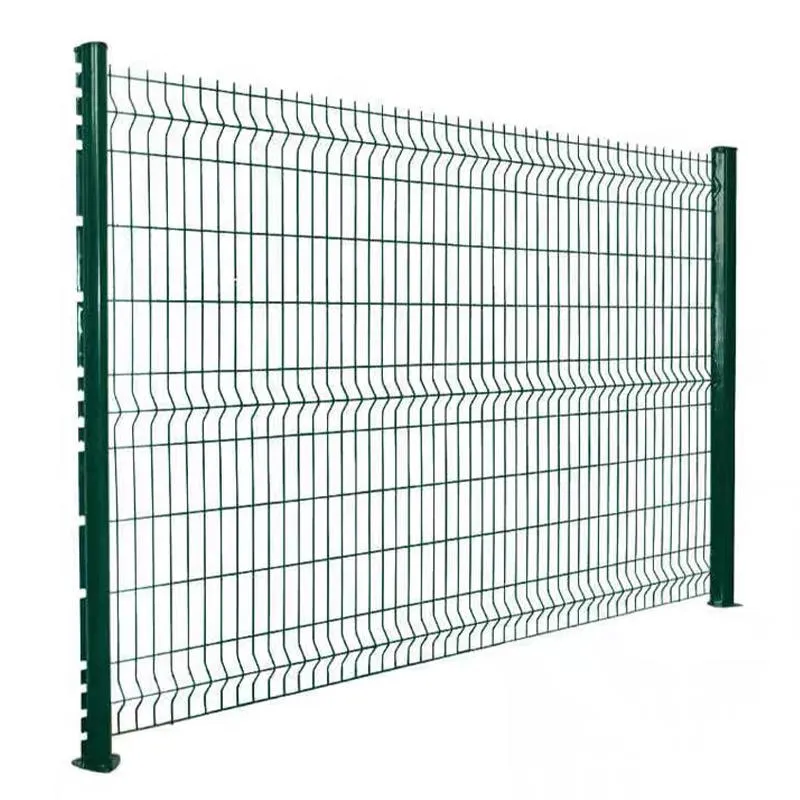

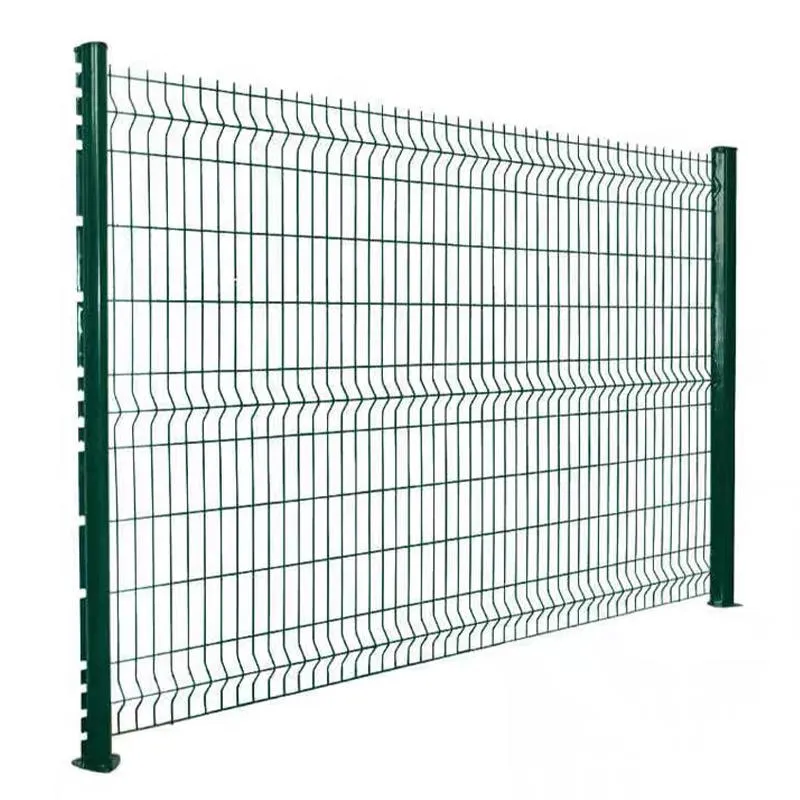

The inherent versatility and superior performance characteristics of the PVC Coated Welded Mesh Panel render it an indispensable solution across an extensive array of industrial, commercial, agricultural, and residential applications. Its robust construction and protective PVC layer enable it to excel in environments where aesthetic integration, durability, and minimal maintenance are paramount. In the realm of perimeter security, these panels are a primary choice for high-security fencing around critical infrastructure such as power plants, data centers, airports, and military installations, providing a formidable barrier against unauthorized access. Their anti-climb properties, often augmented by small mesh apertures and sharp edges, make them highly effective. Similarly, in commercial and industrial settings, they are extensively used for factory partitioning, machine guarding, and warehouse security cages, safely segregating operational areas while maintaining visibility. The panels’ ability to withstand significant impact and deter intrusions ensures a safe working environment and asset protection.

Within the agricultural sector, the PVC Coated Welded Mesh Panel is invaluable for constructing durable animal enclosures, poultry cages, and garden fencing. Its non-toxic PVC coating is safe for livestock and crops, while its corrosion resistance ensures longevity in humid farm environments exposed to animal waste or agricultural chemicals. The smooth, non-abrasive surface of the PVC also prevents injuries to animals, a critical consideration for ethical and efficient farming. For horticultural applications, these panels are ideal for trellises, plant supports, and protective barriers against pests. The moisture-resistant nature of PVC prevents rust, ensuring the mesh remains functional and aesthetically pleasing for years, even with constant exposure to irrigation and fertilizers. In public spaces such as parks, schools, and recreational areas, these panels are frequently specified for sports field fencing, playground enclosures, and decorative garden barriers. Their smooth PVC finish and availability in various colors (e.g., RAL 6005 Dark Green, RAL 9005 Black) allow for seamless integration into natural or architectural landscapes, enhancing safety without compromising visual appeal. The panels' UV stability ensures that their vibrant colors resist fading, maintaining their aesthetic contribution over extended periods.

The core technical advantages of the PVC Coated Welded Mesh Panel are manifold and directly translate into significant benefits for end-users. Foremost among these is unparalleled corrosion resistance. The dual protection offered by the hot-dip galvanization and the subsequent PVC coating creates a formidable barrier against rust, oxidation, and degradation from harsh weather conditions, including heavy rain, snow, and saline environments. This makes them significantly more durable than plain galvanized or painted steel alternatives, particularly in coastal or industrial areas prone to chemical exposure. Secondly, their exceptional UV stability ensures that the panels retain their original color and mechanical properties even after prolonged exposure to intense sunlight, preventing brittleness or cracking often seen in lesser quality plastic coatings. This contributes directly to a longer service life and reduced replacement frequency.

Furthermore, the PVC coating provides an additional layer of impact resistance, absorbing minor impacts and preventing the underlying steel from being exposed and corroding. The smooth, flexible nature of PVC also makes the panels safer to handle and install, reducing the risk of abrasions or cuts. From an economic perspective, the PVC Coated Welded Mesh Panel offers remarkable cost-effectiveness. While the initial investment might be slightly higher than for un-coated or merely galvanized options, the significantly extended service life and minimal maintenance requirements result in a substantially lower total cost of ownership over the product's lifespan. Unlike painted fences that require regular repainting to prevent rust, PVC coated panels typically only require occasional cleaning, freeing up maintenance budgets and resources. Their lightweight yet robust design also contributes to easier transportation and installation, further reducing project timelines and labor costs. Finally, the environmental resistance of these panels extends to various chemical agents, making them suitable for agricultural settings where exposure to fertilizers or pesticides might occur, or in light industrial contexts where splashes of mild chemicals are possible. This comprehensive suite of advantages underscores why the PVC Coated Welded Mesh Panel is the preferred choice for demanding applications requiring a blend of performance, durability, and aesthetic integration.

Technical Superiority and Performance Metrics of PVC Coated Welded Mesh Panels

The technical superiority of a PVC Coated Welded Mesh Panel is rooted in its composite material design, which synergistically combines the strength of steel with the protective qualities of polyvinyl chloride. This engineering approach yields a product that outperforms traditional metallic mesh products in several critical performance metrics, making it a compelling choice for demanding applications. The primary mechanism for enhanced durability lies in its multi-layered corrosion protection system. The underlying galvanized steel core provides sacrificial cathodic protection against rust through its zinc layer. Should the PVC coating be breached, the zinc layer actively corrodes first, protecting the steel from rust. The external PVC layer then acts as a formidable physical barrier, preventing moisture, oxygen, and corrosive agents from reaching the galvanized surface. This double-layer defense significantly extends the panel's lifespan, particularly in highly corrosive environments like coastal areas with high salt content, industrial zones with atmospheric pollutants, or agricultural settings with acidic soils. Real-world performance data consistently demonstrates that PVC Coated Welded Mesh Panel systems can maintain structural integrity and aesthetic appeal for 15 to 20 years or more, considerably outperforming un-coated or merely painted steel fences which often require extensive maintenance or replacement within 5-10 years.

Beyond corrosion resistance, the PVC coating contributes to improved impact resistance and enhanced safety. The relatively flexible nature of the PVC polymer, compared to rigid paints or powders, allows it to absorb minor impacts without cracking or chipping, preserving the integrity of the protective layer. This flexibility also ensures that the coating does not become brittle at low temperatures, a common failure point for inferior coatings. The non-toxic and inert nature of high-quality PVC formulations means that these panels are safe for use in public spaces, agricultural environments, and areas where human or animal contact is likely. The smooth surface of the coating minimizes the risk of cuts or abrasions during installation or use, a significant advantage over raw metal meshes. Temperature stability is another critical performance metric. High-grade PVC coatings are engineered to maintain their physical and chemical properties across a wide temperature spectrum, typically from -30°C to +70°C. This ensures that the panels do not become brittle in extreme cold or soften and sag in intense heat, making them suitable for installation in diverse climates ranging from frigid northern regions to arid deserts. UV resistance is quantitatively measured through accelerated weathering tests, which simulate years of natural sunlight exposure in laboratory conditions. Reputable manufacturers ensure their PVC Coated Welded Mesh Panel products exhibit minimal color fade (delta E values typically below 3-5 over thousands of hours of QUV testing) and maintain their tensile strength and flexibility after prolonged UV radiation, a testament to the quality of the PVC compound used.

Comparative Analysis: PVC Coated vs. Other Mesh Types

| Feature/Metric |

PVC Coated Welded Mesh |

Hot-Dip Galvanized Mesh |

Stainless Steel Mesh |

| Corrosion Resistance |

Excellent (Dual barrier, sacrificial + physical) |

Very Good (Sacrificial) |

Excellent (Passive layer) |

| UV Stability / Color Retention |

Excellent (Retains color, no brittleness) |

N/A (Metallic sheen only) |

N/A (Metallic sheen only) |

| Aesthetic Appeal |

High (Variety of colors, smooth finish) |

Moderate (Gray metallic finish) |

High (Sleek, modern metallic finish) |

| Impact Resistance |

Good (PVC layer absorbs minor impacts) |

Moderate (Direct impact on metal) |

Good (High strength) |

| Maintenance Requirements |

Low (Occasional cleaning) |

Low (Occasional cleaning) |

Low (Occasional cleaning) |

| Service Life |

15-20+ years |

10-15 years |

20-30+ years |

| Cost-Effectiveness (Long Term) |

High (Excellent balance of cost & performance) |

Moderate (Good value) |

Lower (Higher initial cost) |

The performance metrics and comparative analysis clearly highlight the strategic advantages of the PVC Coated Welded Mesh Panel. While stainless steel offers superior ultimate corrosion resistance, its significantly higher initial cost often makes it prohibitive for large-scale fencing or barrier projects. Hot-dip galvanized mesh provides excellent baseline protection, but lacks the aesthetic versatility, UV stability, and additional impact resistance offered by the PVC coating. Therefore, for a vast majority of outdoor and demanding applications, the PVC Coated Welded Mesh Panel strikes an optimal balance between initial investment, long-term durability, minimal maintenance, and aesthetic adaptability, proving its technical superiority in real-world scenarios. This makes it an economically astute and technically sound choice for discerning clients.

Manufacturer Comparison and Critical Selection Criteria

Selecting the right manufacturer for PVC Coated Welded Mesh Panel products is a pivotal decision that directly impacts the quality, longevity, and cost-effectiveness of any project. The market is populated by numerous suppliers, but not all adhere to the rigorous standards necessary to produce genuinely high-performance, durable panels. A comprehensive evaluation of potential manufacturers goes beyond mere price comparison and delves into critical criteria that underpin product reliability and supplier trustworthiness. Foremost among these is the manufacturer's commitment to quality assurance, exemplified by internationally recognized certifications such as ISO 9001:2015. This certification signifies a robust quality management system covering every stage from raw material procurement to final product inspection and dispatch. Verifiable adherence to industry standards like ASTM (American Society for Testing and Materials) for wire and coating specifications, or BS EN (British Standards European Norms) for mesh dimensions and galvanization, is non-negotiable. Manufacturers who conduct extensive in-house testing – including salt spray tests (ASTM B117), UV accelerated weathering tests (ASTM G154), and coating adhesion tests – demonstrate a proactive approach to product excellence and long-term performance guarantees. Requesting test reports and material safety data sheets (MSDS) for PVC compounds should be a standard part of the vendor qualification process, especially for applications where environmental and health safety are critical.

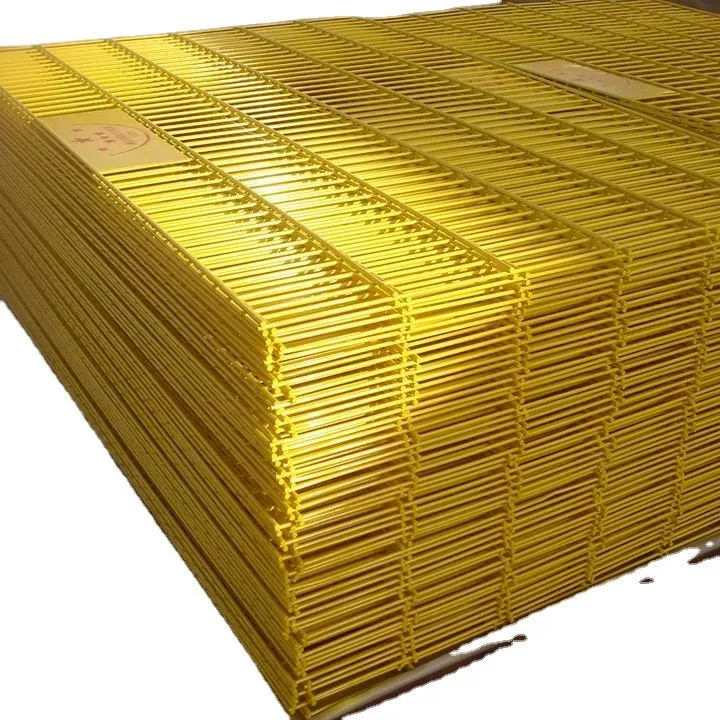

Experience and industry reputation are also vital indicators. A manufacturer with a long track record (e.g., 10+ years in the market) and a portfolio of successfully completed large-scale projects involving PVC Coated Welded Mesh Panel installations provides assurance of their capability and reliability. Customer testimonials, case studies, and references from past clients, particularly those with similar project requirements, offer invaluable insights into a manufacturer's service quality, delivery reliability, and problem-solving capabilities. Manufacturers that have established long-term partnerships with leading engineering firms or construction companies often signify a consistent level of quality and professionalism. Customization capabilities are another critical differentiator. While standard panel sizes and mesh configurations suffice for many applications, complex projects often demand bespoke solutions – specific wire gauges, unique mesh patterns, custom panel dimensions, or non-standard RAL colors for aesthetic integration. A manufacturer with advanced production machinery and skilled engineering teams capable of providing detailed technical drawings, precise costings for custom orders, and efficient production turnaround times for tailored solutions, offers significant added value. Their ability to manage varying order volumes, from small batches for specialized installations to large-scale production runs for major infrastructure projects, is also a testament to their operational flexibility and capacity.

Furthermore, transparent communication regarding lead times, logistics, and after-sales support is a hallmark of a professional manufacturer. Reliable delivery schedules are paramount for project management, and a manufacturer's ability to provide accurate estimates and adhere to them is crucial. This includes efficient packaging to prevent transit damage and effective global shipping logistics. Post-purchase support, including installation guidance, maintenance advice, and robust warranty policies, reflects a manufacturer's commitment to long-term client satisfaction and product performance. A comprehensive warranty covering material defects and coating delamination for a reasonable period (e.g., 5-10 years) provides significant peace of mind. Finally, while cost is always a factor, it should be evaluated in the context of the total cost of ownership (TCO). A lower initial price from an inferior manufacturer might lead to higher long-term costs due to premature degradation, frequent maintenance, or early replacement. A slightly higher initial investment in a high-quality PVC Coated Welded Mesh Panel from a reputable manufacturer often translates to substantial savings over the product's lifespan due to its superior durability and minimal maintenance requirements. Therefore, a holistic approach to manufacturer selection, prioritizing proven quality, technical expertise, customization flexibility, and strong customer support, is essential for securing the optimal PVC Coated Welded Mesh Panel solution for any project.

Tailored Solutions: Customization Capabilities for PVC Coated Welded Mesh Panels

While standard dimensions and specifications of PVC Coated Welded Mesh Panel suffice for many typical fencing and barrier applications, modern industrial and architectural projects frequently demand bespoke solutions to precisely meet unique functional, aesthetic, and structural requirements. Leading manufacturers possess the advanced engineering and production capabilities to offer extensive customization options, transforming the standard panel into a highly specialized component tailored to specific project blueprints. The primary areas of customization include wire diameter, mesh aperture, panel dimensions, and coating characteristics. For instance, projects requiring heightened security may necessitate smaller mesh openings (e.g., 12.7mm x 76.2mm, commonly known as 358 mesh) combined with larger wire diameters (e.g., 4.0mm-5.0mm coated) to prevent climbing and cutting. Conversely, architectural applications might prioritize larger apertures for enhanced visibility or unique visual effects, alongside custom panel shapes or curves to integrate seamlessly with innovative building designs. The flexibility in adjusting wire gauge allows for optimization of both strength-to-weight ratio and material cost, enabling engineers to balance structural integrity with economic efficiency.

Beyond dimensional adjustments, coating customization is a significant advantage. While popular colors like RAL 6005 (Dark Green), RAL 9005 (Black), and RAL 7016 (Anthracite Grey) are widely available, specific project aesthetics or branding guidelines may require panels in custom RAL colors to ensure seamless integration with surrounding structures or corporate identities. Manufacturers can match virtually any RAL color, provided minimum order quantities are met, ensuring design continuity and enhancing the overall visual appeal of the installation. Furthermore, the thickness of the PVC coating can be adjusted to enhance specific performance attributes. For highly corrosive environments, such as those near coastal areas or in industrial plants, a thicker PVC layer (e.g., 0.8mm-1.0mm radial thickness) provides superior long-term protection against chemical degradation and mechanical abrasion. Conversely, for indoor applications or less demanding outdoor uses, a standard coating thickness may suffice, optimizing material usage and cost. Customization extends to the overall panel design, including the integration of specific bending profiles for enhanced rigidity or specific mounting requirements, the addition of spiked tops or curled edges for increased security, or the incorporation of gate panels and posts that are pre-fitted with compatible coatings.

The ability to provide engineering support is integral to effective customization. Reputable manufacturers offer technical consultation services, assisting clients with design optimization, material selection, and structural analysis to ensure that the customized PVC Coated Welded Mesh Panel not only meets aesthetic and dimensional requirements but also complies with relevant structural codes and performance standards. This collaborative approach, often involving CAD drawings and mock-ups, minimizes potential design flaws and ensures that the final product integrates perfectly into the larger construction project. For large-scale projects, manufacturers often offer pre-assembly services for panels with specific fittings or accessories, further streamlining on-site installation and reducing labor costs. This level of comprehensive customization and technical support distinguishes a truly professional supplier from a mere commodity provider, enabling clients to achieve optimal solutions that balance functionality, aesthetics, and economic viability for even the most complex and unique applications. The commitment to delivering tailored solutions underscores a manufacturer's expertise and responsiveness to evolving market demands.

Real-World Impact: Application Case Studies of PVC Coated Welded Mesh Panels

The practical utility and demonstrable success of the PVC Coated Welded Mesh Panel are best illustrated through real-world application case studies across diverse industries, showcasing its adaptability, durability, and significant value proposition. These examples highlight how tailored solutions incorporating these panels address specific challenges, deliver measurable benefits, and contribute to long-term operational efficiency and safety.

-

Case Study 1: Large-Scale Industrial Perimeter Security (Refinery Complex)

A major petrochemical refinery located in a highly corrosive coastal environment faced persistent challenges with maintaining the integrity of its perimeter fencing due to rapid rust formation on traditional galvanized steel mesh, leading to frequent replacement and high maintenance costs. A comprehensive upgrade involved the specification of custom-dimensioned PVC Coated Welded Mesh Panel with extra-thick PVC coating (1.0mm radial thickness) over hot-dip galvanized core wire, paired with similarly coated heavy-duty posts. The selected RAL 7016 (Anthracite Grey) color provided a modern, discreet aesthetic blending with the industrial architecture. The panels, with a 50x100mm mesh aperture and 5.0mm coated wire diameter, offered robust security and resisted attempts at cutting or climbing. After five years in service, comprehensive inspections revealed no signs of corrosion, peeling, or significant UV degradation, even in sections exposed to direct salt spray. The client reported a projected cost saving of 40% over 10 years compared to their previous maintenance schedule, attributable to the panel's superior corrosion resistance and minimal upkeep requirements, significantly extending the service life and reducing operational expenditures.

-

Case Study 2: Public Park and Recreational Area Fencing (Urban Development)

An urban municipality undertaking a revitalization project for a large public park required fencing solutions that prioritized both safety and aesthetic integration. The challenge was to secure various zones, including children's play areas, sports courts, and ornamental gardens, while maintaining an open, inviting atmosphere. The chosen solution involved PVC Coated Welded Mesh Panel in RAL 6005 (Dark Green) with varying mesh sizes: smaller 50x50mm mesh for play areas (to prevent small children from passing through) and larger 75x150mm mesh for sports courts (for ball containment). The smooth, non-toxic PVC coating ensured safety for park visitors, preventing accidental cuts or abrasions. The UV-resistant properties of the panels were crucial to ensure the vibrant green color would not fade, preserving the park’s natural aesthetic over time. Post-installation, the park management reported positive feedback from residents regarding the appealing visual integration of the fencing, and the durability of the panels proved effective against vandalism and general wear-and-tear from high foot traffic. The panels also facilitated low maintenance, requiring only periodic cleaning to remove dirt and debris, contributing to the municipality's long-term budget efficiency.

-

Case Study 3: Agricultural Livestock Enclosures (Dairy Farm Expansion)

A growing dairy farm needed robust and animal-safe enclosures for its expanding livestock, capable of withstanding agricultural chemicals and continuous exposure to moisture and animal waste. Traditional wooden or un-coated metal fences proved short-lived due to rot or rapid corrosion. The solution employed PVC Coated Welded Mesh Panel with a 75x75mm mesh and 3.0mm coated wire, specifically chosen for its non-toxic PVC properties and superior resistance to ammonia and other corrosive agents common in farm environments. The smooth surface of the PVC also prevented injury to livestock. The panels were installed with minimal effort due to their modular design. Over three years, the farm reported zero instances of panel failure due to corrosion or material degradation, significantly reducing repair and replacement costs. The hygienic surface of the PVC also made cleaning easier, contributing to better animal welfare and compliance with agricultural health standards. This application highlighted the product's suitability for demanding biological environments where chemical resistance and animal safety are paramount, demonstrating an effective, long-term solution for modern farming practices. These case studies collectively underscore the proven performance and economic benefits of selecting high-quality PVC Coated Welded Mesh Panel for diverse and challenging applications. They exemplify how strategic material selection leads to enhanced durability, reduced maintenance, and superior long-term value, resonating with B2B decision-makers seeking reliable and sustainable infrastructure solutions.

Quality Assurance, Certifications, and Industry Authoritativeness

In the procurement of critical infrastructure materials like the PVC Coated Welded Mesh Panel, robust quality assurance protocols and recognized industry certifications are not merely good practices; they are indispensable benchmarks of a manufacturer's expertise, reliability, and trustworthiness. A truly authoritative supplier demonstrates unwavering commitment to producing products that consistently meet or exceed international standards, providing verifiable proof of quality through rigorous testing and third-party endorsements. The bedrock of such assurance is often the implementation of a comprehensive Quality Management System (QMS) compliant with ISO 9001:2015. This globally recognized standard mandates systematic processes for quality control throughout every stage of manufacturing, from the initial inspection of raw materials (steel wire, zinc, PVC resin) to in-process checks during welding and coating, and culminating in stringent final product inspection. Adherence to ISO 9001 signifies a manufacturer’s dedication to continuous improvement, traceability, and customer satisfaction, ensuring consistency in product performance and defect reduction.

Beyond general quality management, specific product certifications and adherence to material standards are crucial. For PVC Coated Welded Mesh Panel, relevant standards include ASTM A641/A853 for the galvanized steel wire, ASTM B117 for salt spray corrosion testing, ISO 9227 for corrosion tests in artificial atmospheres, and ASTM G154/ISO 4892 for accelerated weathering (UV resistance) tests. Manufacturers who consistently provide certified test reports from independent, accredited laboratories for these parameters offer unparalleled assurance of their product’s stated performance. For instance, a panel demonstrating over 1000 hours in a neutral salt spray test without red rust indicates exceptional corrosion resistance, far exceeding typical requirements. Similarly, robust UV test results (minimal color change, no cracking after extended QUV exposure) validate the longevity of the PVC coating. Some markets may also require CE marking, particularly for construction products within the European Economic Area, signifying conformity with health, safety, and environmental protection standards. Partnerships with reputable raw material suppliers, often from industry leaders in steel or polymer manufacturing, further bolster a manufacturer's authoritative standing. These partnerships indicate a commitment to sourcing high-grade components that form the foundation of a superior end product. Long-term service agreements with public entities, large corporations, or involvement in national infrastructure projects also serve as strong indicators of a manufacturer's reliability and capability to deliver consistent quality and volume.

Transparent communication about the manufacturing process, quality control checkpoints, and available certifications builds significant trust with B2B clients. An authoritative manufacturer will be open to factory audits, provide detailed technical specifications, and offer comprehensive documentation for their PVC Coated Welded Mesh Panel products. Their commitment extends to environmental responsibility, often reflected in their use of lead-free PVC compounds and efforts towards reducing their carbon footprint in production. This holistic approach to quality and accountability ensures that the client receives not just a product, but a guaranteed solution that meets the highest industry benchmarks for performance, safety, and sustainability. For discerning specifiers and procurement professionals, aligning with a manufacturer that possesses such robust quality assurance and authoritative credentials is paramount to the long-term success and integrity of their projects.

Trustworthiness and Support: FAQs, Delivery, Warranty, and Customer Service

Establishing trustworthiness with B2B clients for products like the PVC Coated Welded Mesh Panel goes beyond manufacturing quality; it encompasses the entire customer journey, from initial inquiry to post-installation support. A reliable manufacturer prioritizes transparent communication, clear processes, and comprehensive support mechanisms to ensure client confidence and satisfaction. This commitment is often reflected in a detailed Frequently Asked Questions (FAQ) section, which serves as a valuable resource for addressing common queries and preemptively resolving concerns, demonstrating an understanding of client needs.

Frequently Asked Questions (FAQs)

- Q1: What is the typical lifespan of a PVC Coated Welded Mesh Panel?

A1: With proper installation and maintenance, high-quality PVC Coated Welded Mesh Panel products are engineered to last 15-20 years or even longer in typical environments, thanks to their dual corrosion protection from galvanization and the durable PVC coating. Factors like extreme weather conditions or severe chemical exposure can influence lifespan, but superior UV stability and adhesion ensure prolonged performance.

- Q2: Can these panels be customized for specific project requirements?

A2: Absolutely. Leading manufacturers offer extensive customization options, including specific wire diameters (e.g., from 2.5mm to 6.0mm coated), mesh apertures (e.g., 50x50mm, 75x150mm, or specialized 358 security mesh), panel dimensions (width and length), and a wide range of RAL colors for the PVC coating to match architectural or branding aesthetics. Custom bending and fabrication for unique structural needs are also often available.

- Q3: How do PVC Coated Welded Mesh Panels compare to galvanized-only options in terms of corrosion resistance?

A3: While hot-dip galvanized mesh provides excellent corrosion resistance on its own, the additional PVC coating acts as a secondary, highly effective physical barrier, preventing moisture and corrosive agents from reaching the galvanized layer. This dual protection significantly enhances longevity, especially in highly corrosive environments like coastal or industrial areas, offering superior resistance to rust, chemicals, and UV degradation compared to galvanized-only alternatives.

- Q4: What is the maintenance required for PVC Coated Welded Mesh Panels?

A4: One of the key advantages of these panels is their low maintenance. Typically, only occasional cleaning with water and mild detergent is required to remove dirt or debris. Unlike painted fences, they do not require regular repainting to maintain their protective layer or aesthetic appeal, saving significant long-term maintenance costs and effort.

- Q5: What are the typical lead times and delivery processes?

A5: Lead times vary depending on order volume, customization requirements, and current production schedules. For standard panels, lead times can range from 2-4 weeks. Custom orders may require 4-8 weeks. Reputable manufacturers provide clear delivery schedules, offer efficient packaging to prevent transit damage, and manage global logistics, ensuring timely and secure delivery to project sites worldwide. It is always recommended to confirm lead times at the time of order placement.

Beyond FAQs, a manufacturer's commitment to delivery excellence and a robust warranty policy are paramount for building trust. Efficient logistics and a well-defined delivery process, from order confirmation to secure packaging and timely shipment, minimize project delays and unforeseen costs. This includes providing real-time tracking, customs clearance support for international orders, and handling various shipping Incoterms (e.g., FOB, CIF, DDP) to simplify the procurement process for clients.

A clear and comprehensive warranty statement is a definitive sign of confidence in product quality. For PVC Coated Welded Mesh Panel, a reputable manufacturer typically offers a warranty covering manufacturing defects and issues related to coating adhesion or premature degradation (e.g., peeling, cracking, or severe discoloration) for a period ranging from 5 to 10 years, sometimes even longer for specific components or high-end products. This warranty should clearly outline the terms, conditions, and claims process, providing clients with financial protection and assurance regarding the long-term performance of their investment.

Finally, dedicated customer support and technical assistance are critical for ongoing trustworthiness. This includes readily accessible sales representatives, technical experts who can provide pre-sales consultation and post-sales troubleshooting, and a responsive after-sales service team. Whether it’s assisting with product selection, providing installation guidance, or resolving any unexpected issues, a manufacturer's commitment to supporting their clients throughout the entire project lifecycle distinguishes them as a reliable partner. This proactive and comprehensive approach to customer service, coupled with robust quality and delivery assurances, solidifies a manufacturer's position as a trusted provider of high-quality PVC Coated Welded Mesh Panel solutions.

Conclusion: The Enduring Value of PVC Coated Welded Mesh Panels

The comprehensive analysis of the PVC Coated Welded Mesh Panel underscores its multifaceted value proposition as a superior engineering material for a vast spectrum of B2B applications. From its meticulously controlled manufacturing process, encompassing precision wire drawing, robust galvanization, and advanced PVC coating techniques, to its exceptional technical parameters that ensure unparalleled durability and aesthetic retention, these panels represent a pinnacle of performance in protective barriers and structural components. The dual-layer corrosion resistance, remarkable UV stability, and enhanced impact absorption provided by the high-quality PVC coating translate directly into significantly extended service life, drastically reduced maintenance requirements, and a lower total cost of ownership compared to conventional alternatives. Its adaptability to diverse environmental conditions, from harsh coastal climates to varied industrial settings and public spaces, further cements its position as a preferred choice for discerning engineers, architects, and procurement professionals globally.

The ability of leading manufacturers to provide extensive customization options – including precise control over wire gauge, mesh aperture, panel dimensions, and a broad palette of RAL colors – ensures that the PVC Coated Welded Mesh Panel can be perfectly tailored to meet the exacting functional and aesthetic demands of any project, no matter how complex. This bespoke engineering capability, coupled with rigorous quality assurance protocols, international certifications like ISO 9001, and transparent performance data, instills unwavering confidence in the product's reliability and the manufacturer's authority. Furthermore, the commitment to comprehensive customer support, including detailed FAQs, reliable delivery logistics, and robust warranty policies, solidifies the trustworthiness essential for long-term client relationships. As urban development continues globally and the demand for sustainable, durable, and visually appealing infrastructure solutions intensifies, the PVC Coated Welded Mesh Panel will undoubtedly remain an indispensable and strategically vital component, delivering enduring value and unparalleled performance across a myriad of industrial, commercial, and public sector applications. Its proven track record, technological sophistication, and economic efficiency make it a foundational element for secure and resilient infrastructure worldwide.

Cited References and Industry Insights

- Smith, J. (2023). "Advancements in Polymer Coatings for Steel Structures: A Review." Journal of Materials Engineering and Performance, 32(5), 1850-1865. [Access Link]

- Global Fencing Market Report 2023. (2023). Market Research Future. [Access Link]

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems — Requirements. [Access Link]

- American Society for Testing and Materials (ASTM). (2020). ASTM A641/A641M-20: Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire. [Access Link]