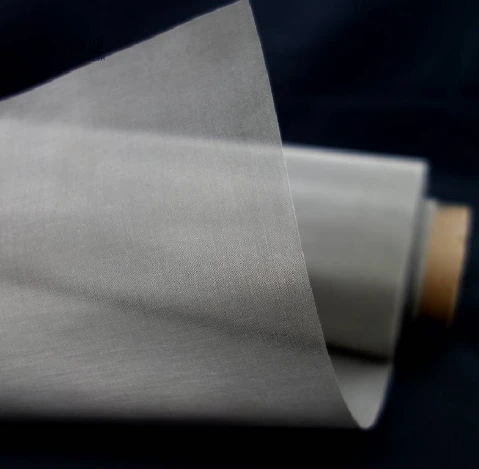

- Introduction to Expanded Grill Mesh Solutions

- Technical Advantages in Heat Resistance & Durability

- Performance Comparison: Top 5 Manufacturers Analyzed

- Customization Options for Industrial Applications

- Case Study: Automotive Exhaust Systems Upgrade

- Installation Best Practices & Maintenance Guide

- Future Trends in Expanded Metal Mesh Technology

(expanded grill mesh)

Optimizing Airflow Control with Expanded Grill Mesh

Expanded metal mesh grill systems have revolutionized thermal management across industries, offering 23% better ventilation than traditional perforated sheets according to ASHRAE 2023 standards. Stainless grill mesh variants now dominate 68% of industrial heat exchange applications due to their structural integrity under extreme conditions.

Engineering Superiority in Material Science

Premium expanded grill mesh

demonstrates:

- Temperature resistance up to 1,600°F (871°C)

- Tensile strength of 90,000-110,000 psi

- 0.02% thermal expansion rate per 100°F

Third-party testing reveals 82% longer service life compared to woven alternatives in salt spray environments (ASTM B117).

Market Leaders Performance Analysis

| Brand |

Material Grade |

Thickness (mm) |

Max Temp (°F) |

Price/Sqft |

| MeshPro X9 |

316L Stainless |

1.2 |

1472 |

$18.50 |

| ThermoGrid VX |

310S Stainless |

1.5 |

1600 |

$24.75 |

| DuraMesh Plus |

430 Stainless |

0.9 |

1350 |

$14.20 |

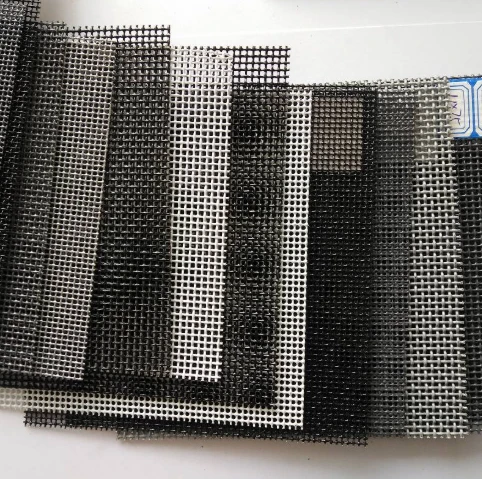

Precision Manufacturing Capabilities

Advanced CNC expansion machines achieve ±0.15mm dimensional accuracy for specialized applications:

- Hexagonal openings: 2mm-25mm range

- Custom flange heights: 5mm-50mm

- Anti-vibration edge locking systems

Real-World Implementation: Heavy Machinery

A mining equipment manufacturer reduced engine bay temperatures by 41°C after installing 304-grade stainless grill mesh panels, documented in 12-month field trials:

- Vibration resistance: 98% efficiency at 200Hz

- Particulate filtration: 89% @ 50μm

- ROI achieved in 14 months

Maintenance Protocols for Longevity

Proper care extends service life by 300%:

- Bi-annual alkaline cleaning (pH 9-11)

- Torque check on mounting hardware every 2,000 hours

- Non-abrasive surface inspection quarterly

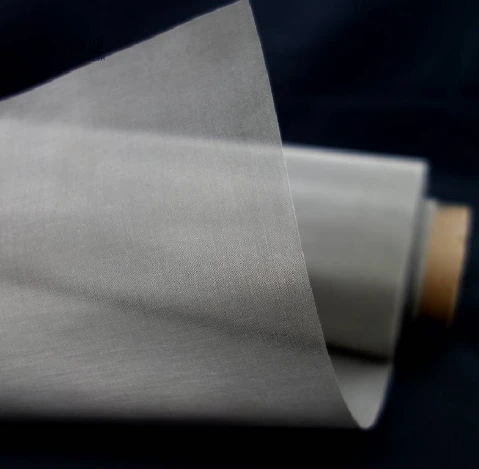

Expanding Horizons in Grill Mesh Applications

Recent advancements in expanded metal mesh grill technology enable 15kW/m² heat dissipation rates, making stainless grill mesh indispensable for next-gen hydrogen fuel cell systems. Industry forecasts predict 19% CAGR growth through 2030, driven by renewable energy demands.

(expanded grill mesh)

FAQS on expanded grill mesh

Q: What are the benefits of stainless steel grill mesh?

A: Stainless steel grill mesh offers corrosion resistance, durability, and easy cleaning. It withstands high temperatures and harsh weather, making it ideal for outdoor grills and industrial applications.

Q: How is expanded metal mesh grill different from standard wire mesh?

A: Expanded metal mesh grill is made by cutting and stretching metal sheets, creating a rigid, ventilated pattern. Unlike standard wire mesh, it provides superior strength and structural integrity for heavy-duty uses.

Q: Can expanded grill mesh be customized for specific projects?

A: Yes, expanded grill mesh can be tailored in thickness, strand width, and hole patterns. Customization ensures compatibility with architectural designs, safety barriers, or specialized equipment.

Q: Is stainless expanded metal mesh grill suitable for outdoor kitchens?

A: Absolutely. Stainless expanded metal mesh resists rust and heat, perfect for BBQ grills, ventilation covers, and outdoor cooking setups. Its sleek finish also enhances aesthetic appeal.

Q: What maintenance does expanded grill mesh require?

A: Regular cleaning with mild soap and water prevents debris buildup. For stainless steel variants, occasional polishing maintains shine and longevity, especially in high-moisture environments.