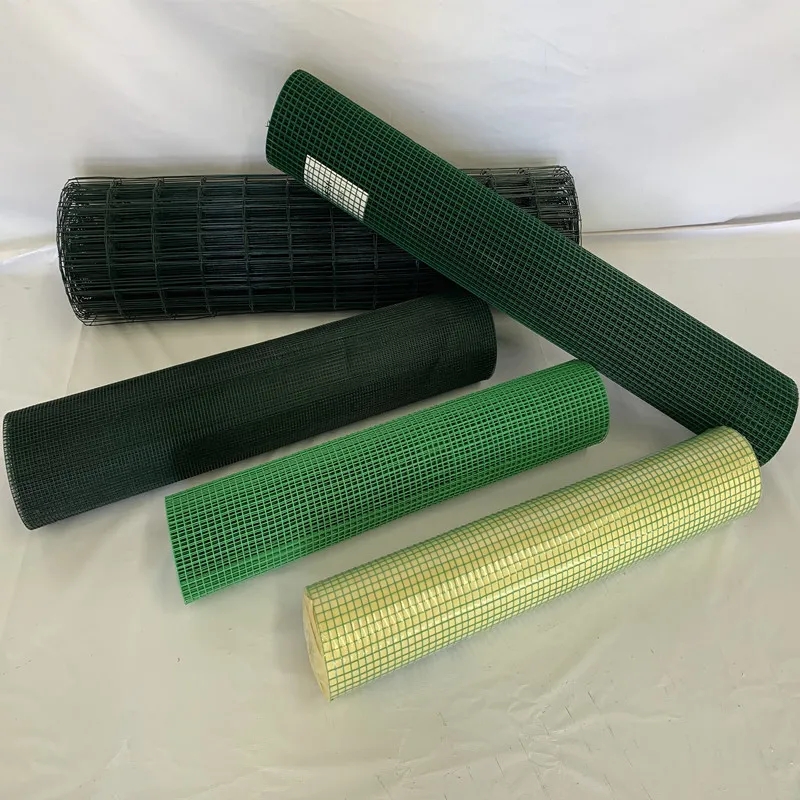

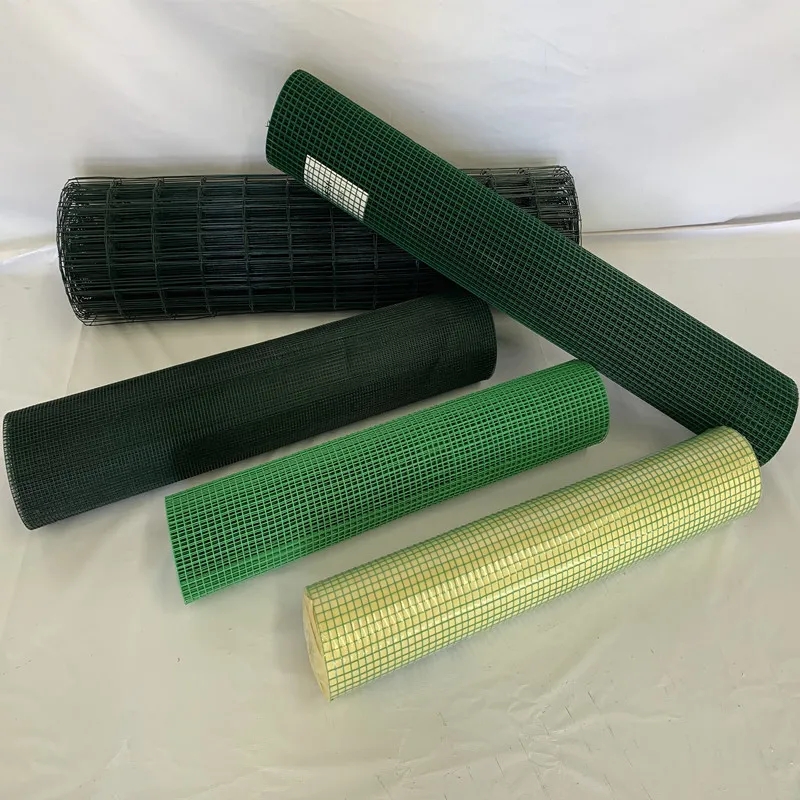

Understanding the Advantages of Coated Expanded Metal Mesh

Coated expanded metal mesh stands out as an exceedingly versatile material with numerous applications across various industries. What sets this material apart is not just its inherent strength and adaptability, but also the additional benefits introduced through advanced coating techniques.

To begin with,

the process of creating expanded metal mesh involves stretching and expanding a sheet of metal to form a mesh with diamond-shaped voids. This procedure enhances the metal’s strength-to-weight ratio without adding additional weight, offering a combination of strength and flexibility that can withstand substantial stress. By applying specialized coatings, we can significantly augment the material's properties, thereby extending its utility and durability.

Those experienced with coated expanded metal mesh can attest to its remarkable corrosion resistance. Without proper protection, metals are prone to rust, especially in environments exposed to moisture or chemicals. A high-quality coating serves as a barrier, shielding the metal from oxidative elements and effectively preventing rust. This is particularly crucial in architectural applications or industrial settings where environmental exposure is inevitable.

From an expertise viewpoint, choosing the right coating for expanded metal mesh requires a deep understanding of the working conditions and the specific demands of each application. For instance, in humid or coastal areas where salt-laden air can be particularly corrosive, a coating with rust-inhibitive properties is indispensable. Epoxy coatings are a popular choice due to their excellent protective qualities and their ability to withstand chemicals and moisture. Powder coatings, on the other hand, provide a hard finish that is tougher than conventional paint, making them ideal for heavy-duty applications.

coated expanded metal mesh

A critical aspect highlighted by industry experts is the aesthetic versatility offered by these coatings. Beyond protection, coatings allow expanded metal mesh to be customized in various colors and finishes, enabling designers and architects to integrate these meshes into their visions seamlessly. Whether for decorative facades, interior design elements, or art installations, the coating can complement or contrast with other materials, providing both functional and artistic value.

The authoritativeness of coated expanded metal mesh is underscored by its widespread acceptance in industries such as construction, automotive, and aerospace. Its reliability is not only due to its structural benefits but also because of its adaptability to different environmental challenges. Architectural projects around the world utilize this material for cladding systems, which benefit from the added layer of UV protection offered by certain specialized coatings, ensuring longevity and minimal maintenance over time.

Furthermore, the trustworthiness of coated expanded metal mesh is amplified by its use in safety and security sectors. Facilities often employ this material for fencing, barriers, and screens where strength is critical, and the risk of corrosion could compromise safety. By choosing a coated variant, organizations can rely on long-term performance without incurring frequent replacement costs or undergoing extensive repairs.

In addition to safety and aesthetics, sustainability is another domain where coated expanded metal mesh shines. The metal itself can be recycled, and with advancements in eco-friendly coatings, the production process aligns with sustainable practices. Companies pursuing green certifications can benefit from using materials like coated expanded metal mesh, reducing environmental impact while maintaining structural integrity.

With a synthesis of strength, durability, aesthetic potential, and sustainability, coated expanded metal mesh is not just a product, but a comprehensive solution embraced by experts across multiple disciplines. Its ability to adapt to evolving industry standards while maintaining superior performance makes it a reliable choice for projects demanding excellence in both form and function. For those considering the application of coated expanded metal mesh, tapping into professional expertise can ensure that the right solution is chosen, maximizing both the material's longevity and value in any given context.