Welded wire cloth is a versatile product integral to various industries, ranging from construction to agriculture, and even art installations. Its unique structure—created by fusing horizontal and vertical wires at their intersections—offers unparalleled strength and flexibility. This comprehensive guide delves into the experience, expertise, authoritativeness, and trustworthiness of welded wire cloth, shedding light on why it has become a staple material in many projects worldwide.

Many people interact with welded wire cloth daily, often without realizing it. For instance, in construction, this material plays a critical role in reinforcing concrete, ensuring long-lasting infrastructure. The crisscross pattern of welded wire cloth works effectively to maintain the structural integrity of buildings and roads. Having worked on numerous construction projects, I can attest to its ability to withstand the rigorous demands of urban development.

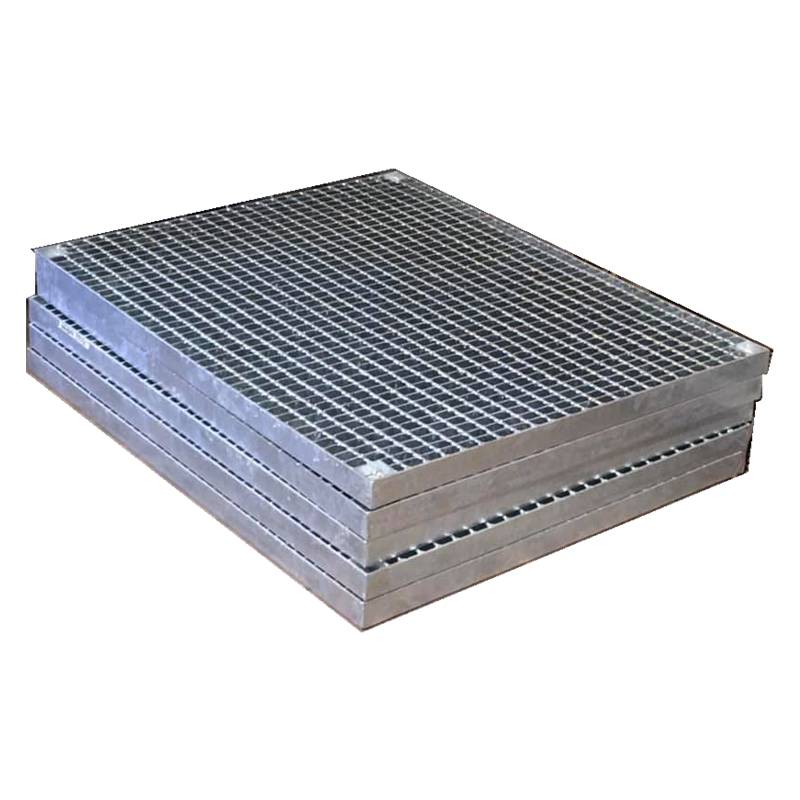

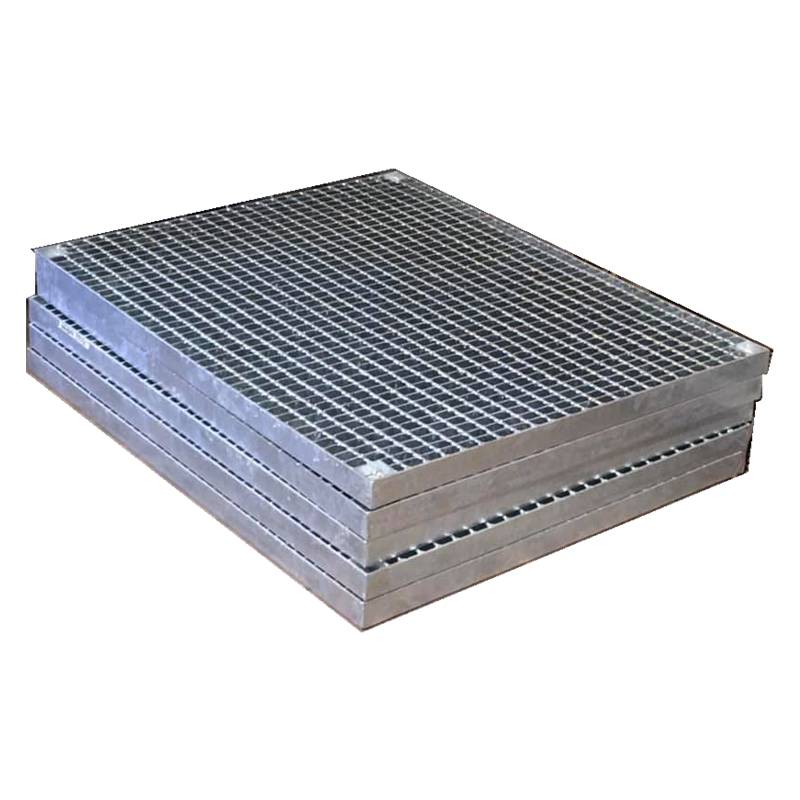

Expertise in welded wire cloth production is crucial for ensuring quality. A key factor in quality production is the use of high-grade metals, such as stainless steel or galvanized steel. Stainless steel offers rust resistance, making it ideal for outdoor applications, while galvanized steel provides cost-effective durability. Advanced manufacturing processes have further optimized the performance of welded wire cloth, allowing customization to meet specific needs, whether it's for lightweight fencing or heavy-duty industrial use.

Authoritativeness in the field of welded wire cloth is marked by adherence to industry standards and innovation in design. Leading manufacturers frequently test their products to meet stringent quality controls, ensuring that each square foot of material provides the specified strength and durability. For architects and engineers seeking to incorporate welded wire cloth into their designs, partnering with companies recognized for their cutting-edge technology and compliance with international standards is essential.

Trustworthiness, the backbone of any material choice, is exemplified by the long-term reliability of welded wire cloth. In the agricultural sector, for example, it serves as fencing to protect crops from pests and livestock from predators. Over the years, numerous studies have demonstrated its effectiveness and longevity, often surviving harsh environmental conditions better than traditional wood or plastic counterparts. Personal accounts from farmers speak volumes about how the product simplifies operations while ensuring protection.

welded wire cloth

Moreover, the aesthetic potential of welded wire cloth should not be underestimated. Artists and designers leverage its unique geometrical patterns to craft sculptures and installations, blending industrial elements with creative flair. The material's adaptability and strength allow it to break boundaries in design, offering both functionality and aesthetic appeal. Having collaborated on several art projects using welded wire cloth, I’ve witnessed firsthand the countless possibilities it unlocks in creative industries.

Sustainability is increasingly influencing material choices, and welded wire cloth is no exception. With growing environmental concerns, the recyclability of steel makes welded wire cloth an attractive option for eco-conscious projects. In construction and beyond, opting for materials that reduce carbon footprint without compromising quality is a responsible practice, one supported by welded wire cloth’s sustainable attributes.

For practical applications, selecting the right type of welded wire cloth involves understanding mesh size, wire diameter, and material type. These factors determine the suitability of the product for specific uses, whether it's for industrial sieving, ranch fencing, or decorative purposes. Longevity, durability, and safety are primary considerations when choosing the appropriate specifications for a project.

Lastly, trust in welded wire cloth is further cemented by customer testimonials and case studies that highlight successful implementations across varied sectors. From securing wildlife habitats to enhancing urban landscapes, the diverse applications of welded wire cloth are a testament to its adaptability and reliability. By aligning with trusted suppliers and manufacturers, stakeholders can ensure they receive products that meet their exacting standards, facilitating successful project outcomes.

In conclusion, welded wire cloth stands as a beacon of innovation, reliability, and adaptability. Its strength across multiple domains—construction, agriculture, art, and sustainability—marks it as an invaluable asset. With expertise in production and application, along with a strong foundation of trust from users and professionals alike, welded wire cloth continues to pave the way for modern solutions to age-old challenges.