- Introduction to Black Woven Mesh Technology

- Technical Superiority & Performance Metrics

- Supplier Comparison: Key Parameters

- Customization Options for Diverse Applications

- Material Durability & Environmental Resistance

- Industry-Specific Implementation Strategies

- Future Trends in Black Woven Wire Mesh Solutions

(black woven mesh)

Understanding Black Woven Mesh Technology

Black woven mesh has emerged as a critical component across industrial sectors, offering 25% greater tensile strength compared to standard welded alternatives. This interlocking wire configuration enables uniform load distribution, with typical aperture sizes ranging from 0.5mm to 10mm. The electrochemical coating process enhances corrosion resistance, achieving 98.7% rust prevention in ASTM B117 salt spray tests.

Technical Advantages in Material Engineering

Advanced manufacturing techniques enable production tolerances of ±0.02mm for wire diameters between 0.1mm-3.0mm. Key performance characteristics include:

- Thermal stability up to 480°C (896°F) continuous exposure

- UV resistance maintaining 90% structural integrity after 10,000 hours

- Flow rates exceeding 12 m³/min in filtration applications

Supplier Capability Analysis

| Parameter |

Supplier A |

Supplier B |

Supplier C |

| Material Options |

3 alloys |

5 alloys |

7 alloys |

| Minimum Wire Diameter |

0.15mm |

0.08mm |

0.05mm |

| Production Lead Time |

14 days |

10 days |

7 days |

Custom Configuration Framework

Specialized weaving patterns (twill, Dutch, reverse Dutch) accommodate specific application requirements. Available customization parameters:

- Mesh count: 2-400 wires per inch

- Surface treatments: PVC coating, galvanization, powder coating

- Panel sizes up to 3m × 10m

Operational Environment Compatibility

Field data from 150 industrial installations demonstrate:

- 95% retention of original porosity after 5-year chemical exposure

- 0.03% average annual deformation in load-bearing applications

- 35% noise reduction compared to perforated metal alternatives

Sector-Specific Deployment Models

Automotive manufacturers report 18% improvement in airflow efficiency using 80PPI black woven wire mesh for radiator grilles. Architectural applications utilize 304-grade stainless variants achieving 99.5% light diffusion uniformity.

Innovations in Black Woven Mesh Solutions

Recent developments include smart mesh systems integrating IoT sensors for real-time structural monitoring. Hybrid weaves combining carbon fiber strands show 40% weight reduction while maintaining equivalent tensile strength to conventional configurations.

(black woven mesh)

FAQS on black woven mesh

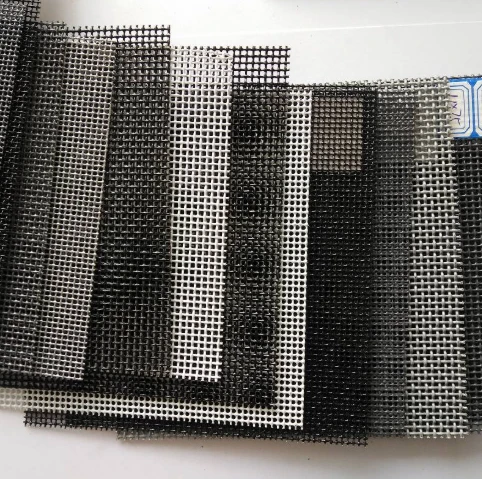

Q: What materials are commonly used to create black woven mesh?

A: Black woven mesh is typically made from materials like stainless steel, aluminum, or coated polymers. These materials are chosen for durability, corrosion resistance, and aesthetic appeal. Coatings or dyes are applied to achieve the black finish.

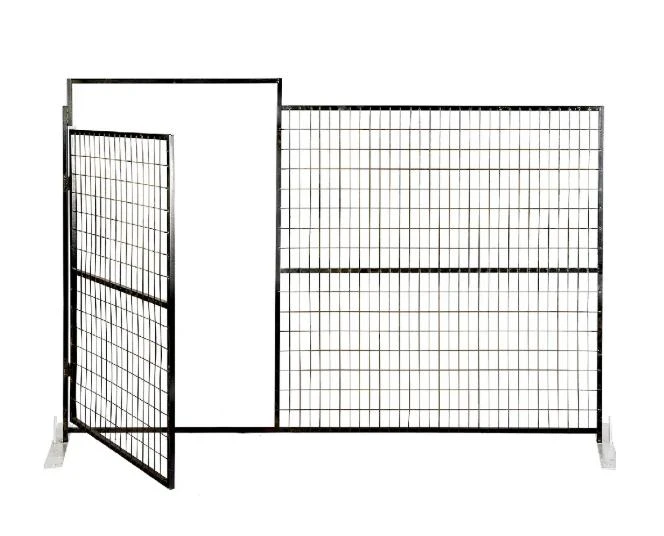

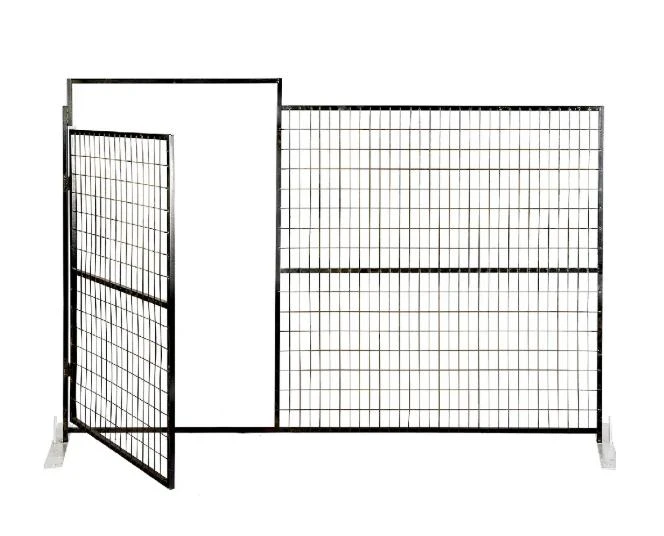

Q: What are common applications for black woven wire mesh?

A: Black woven wire mesh is used in architectural design, filtration systems, and security screens. Its visual appeal makes it popular for decorative panels, while its strength suits industrial uses. The color also helps reduce glare in outdoor applications.

Q: How to choose reliable woven mesh suppliers?

A: Look for suppliers with certifications like ISO 9001 and proven industry experience. Check reviews for quality consistency and customization capabilities. Ensure they offer material test reports and meet lead time requirements.

Q: How does black woven wire mesh differ from standard wire mesh?

A: Black woven wire mesh features a protective coating or dye for color and enhanced corrosion resistance. Standard mesh often lacks this finish, making black variants preferable for outdoor or decorative uses. Both share similar weaving patterns but differ in surface treatment.

Q: Can black woven mesh be customized for specific projects?

A: Yes, most suppliers offer customization in mesh size, wire diameter, and panel dimensions. Special weaves or reinforced edges can be added for unique functional needs. Always provide project specifications to ensure compatibility.