Isabella Rossi

Real Estate Manager, Italy

Application

Chain link fence is great for many different applications including warehouse, industrial, security, residential, parks, playgrounds, gates and dog kennels. Among its most important features are its uniform zinc coating and precise top mesh finishing. The advantages of this chain link are that it is easy to handle and store, it is a competitively-priced product, easy to install and corrosion resistant.

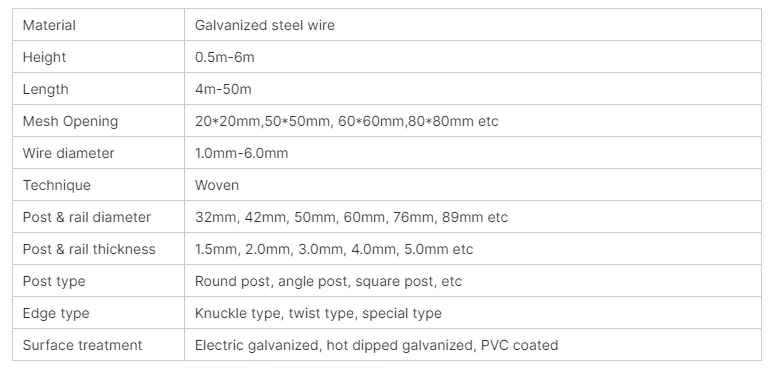

Specification details

When it comes to choosing the right chain wire fencing solution for your property or project, understanding the structural differences between welded wire mesh and chain link fence is essential. At first glance, the two products may appear similar—they both create a grid of interconnected wires that provide security and boundary definition—but their design, durability, and applications set them apart. Knowing these differences allows buyers to select the most practical and cost-effective solution for commercial, industrial, or residential projects.

The structure of each product is the primary distinguishing factor. A chain link fence, also called a chain fence or diamond mesh fence, consists of heavy-gauge wires that are bent and interwoven together. Each wire twists slightly to “snuggle” with its neighbor at every intersection, forming a flexible yet strong mesh. This interwoven design allows the fence to absorb impact and adapt to uneven terrain without breaking. The flexibility of chain link fence wire makes it ideal for long stretches, sloped driveways, or areas where a slightly forgiving barrier is necessary. Galvanized or PVC-coated options, such as a galvanized chain link fence or a green garden chain fence, enhance durability and provide corrosion resistance for outdoor installations.

In contrast, welded wire mesh is constructed by joining horizontal and vertical wires at every intersection using a welding process. This creates rigid squares or rectangles that do not flex like chain link fencing. Because each intersection is fixed, welded wire mesh offers a higher degree of stability and strength against deformation, making it suitable for applications requiring rigid barriers, such as cages, partitions, or certain industrial enclosures. However, the lack of flexibility can be a limitation for areas with uneven ground or where fence panels need to be extended over long distances. Unlike chain wire fencing, welded mesh may require additional support posts to maintain its shape and stability.

Functionality also varies between these two types of fencing. Chain fence excels in versatility; it can be used for residential gardens, driveways, sports fields, or industrial perimeters, and it can be enhanced with chain fence privacy slats for added discretion. Its open structure allows visibility while still providing security, and its flexibility reduces installation time and labor costs. On the other hand, welded wire mesh is often chosen for specialized applications where rigid containment is critical, such as animal enclosures, storage cages, or temporary construction barriers. Its solid intersections provide a neat and professional appearance that is less adaptable for landscaping but highly effective for controlled environments.

From a maintenance perspective, both chain wire fencing and welded wire mesh benefit from protective coatings. Galvanization prevents rust and corrosion, and PVC coatings provide color options and aesthetic appeal, particularly for garden chain fence or driveway chain fence applications. However, chain link fencing’s inherent flexibility often makes it easier to repair minor damages—twisted links can be replaced without disturbing the entire panel—while welded wire mesh may require full panel replacement if any section is compromised. For commercial buyers seeking a balance of durability, adaptability, and cost-effectiveness, chain link fence wire from experienced suppliers offers a practical solution that combines long-term reliability with aesthetic and functional versatility.

Securing a chain wire fencing system to the ground is a critical step for ensuring its stability, durability, and overall effectiveness. Whether you are installing a galvanized chain link fence around an industrial yard, a driveway chain fence, or a garden chain fence, proper anchoring prevents sagging, minimizes maintenance, and enhances security. Several methods can be applied, depending on the type of terrain, fence height, and the level of permanence required. Each technique ensures that your chain fence performs optimally in real-life conditions while maintaining structural integrity.

Stakes or U-Pins: One of the most common and practical methods for securing a chain link fence wire is using metal stakes or U-pins. These stakes are driven into the ground at regular intervals along the base of the fence, holding the mesh tight against the soil. This method is particularly effective for temporary or semi-permanent fencing where easy adjustment or relocation may be necessary. For B2B buyers managing large properties, such as commercial facilities or construction sites, using stakes or U-pins allows quick installation of a chain fence without extensive equipment or labor. This method works well with both galvanized chain link fence and PVC-coated wire mesh fencing, ensuring that the fence maintains its position even under wind or light impact.

Concrete Barrier Method: For a more permanent solution, a concrete barrier can be installed to anchor the bottom of a chain link fence. This involves digging a shallow trench along the fence line, mixing concrete, and pouring it directly into the trench to hold the fence base. Once the concrete cures fully, the trench is backfilled, creating a solid foundation that prevents the fence from shifting. This technique is ideal for high-security installations, heavy-duty chain fence privacy applications, or areas prone to strong winds. A concrete-anchored fence not only improves stability but also enhances longevity, making it a preferred choice for industrial, commercial, or long-term outdoor projects.

Additional Tips for Effective Installation: Regardless of the anchoring method, spacing is key. Stakes or U-pins should be placed at consistent intervals—typically 12 to 18 inches apart—to distribute tension along the base of the chain fence evenly. For driveway chain fence applications, consider combining U-pins with a slight trench to further prevent vehicles from lifting the mesh. Using high-quality chain link fence wire from reputable suppliers ensures that the wire remains taut and resistant to corrosion, whether in concrete or soil. In addition, applying PVC coatings or slats not only enhances durability but also adds aesthetic appeal for garden chain fence installations.

Properly fastening a chain wire fencing system to the ground significantly increases its functionality, safety, and lifespan. By selecting the appropriate anchoring method—whether stakes, U-pins, or a concrete barrier—you can maintain a strong and secure perimeter for any commercial or residential project. Trusted suppliers like SHENZHOU TIKE METAL CO., LTD provide high-quality chain fence solutions, including galvanized chain link fence and PVC-coated chain link fence wire, that are optimized for easy installation, durability, and long-term performance. Investing in professional-grade materials and following best installation practices ensures that your chain fence remains a reliable and visually appealing security solution.

When evaluating fencing options for commercial or residential projects, cost is often a top consideration. A chain fence is generally more cost-effective than wood fencing due to several factors, making it an attractive choice for B2B buyers, property developers, and large-scale installations. The base materials for chain link fence wire are relatively inexpensive, especially when using galvanized chain link fence for durability and corrosion resistance. In contrast, wood fences require high-quality timber, which can be costly depending on the species, treatment, and thickness. For long perimeter projects, the difference in material cost alone can be substantial.

Labor is another area where chain wire fencing saves money. Installing a chain fence is generally faster and less labor-intensive than building a wood fence. Pre-fabricated rolls of chain link fence wire can be unrolled and attached to posts quickly, whereas wood fences require cutting, fitting, nailing, and often staining or sealing for weather protection. A driveway chain fence or garden chain fence can be erected over uneven terrain without additional grading, which further reduces installation costs. For commercial buyers managing large sites or multiple properties, these savings in time and labor translate directly into lower project costs.

While chain link fence is more affordable initially, add-ons and customization options can affect the total cost per foot. For example, chain fence privacy slats, PVC coatings in various colors, or gates can raise the investment, similar to adding decorative elements to a wood fence. A PVC-coated garden chain fence in dark green may offer aesthetic appeal comparable to wood while maintaining superior durability. These optional enhancements allow B2B buyers to balance cost, functionality, and appearance, achieving the desired professional look without compromising the benefits of a chain wire fencing system.

Finally, the long-term cost advantage of a chain fence becomes apparent in maintenance. Unlike wood, which can rot, warp, or require periodic staining and sealing, chain link fence wire—especially galvanized chain link fence—requires minimal upkeep. This durability ensures that your perimeter security remains effective for years with little ongoing expense. For commercial properties, industrial sites, or high-traffic areas, investing in chain wire fencing from reputable suppliers like SHENZHOU TIKE METAL CO., LTD provides a cost-efficient, low-maintenance, and versatile solution that outperforms wood fencing in both practicality and total lifecycle value.

A chain fence is renowned not only for its affordability but also for its durability, making it a preferred choice for commercial, industrial, and residential applications. On average, high-quality chain wire fencing can last upwards of 20 years with proper installation and care. The longevity depends on several factors, including the type of material, protective coatings, and environmental conditions. For B2B buyers managing large properties or perimeter security projects, knowing the expected lifespan of a galvanized chain link fence helps in planning maintenance budgets and long-term investments.

The material and coating play a critical role in determining how long a chain link fence wire will last. Standard galvanized steel wire offers excellent corrosion resistance, protecting the fence from rain, humidity, and outdoor exposure. For enhanced longevity, PVC or powder-coated finishes are available, which add an extra layer of protection against rust and UV damage. A dark green garden chain fence with a powder coating not only maintains its structural integrity for decades but also retains its aesthetic appeal over time, making it ideal for both decorative and security purposes.

Maintenance also affects the lifespan of a chain fence. Simple practices, such as keeping vegetation away from the base, inspecting for bent links or loose posts, and addressing minor rust spots early, can extend the fence’s functional life. For industrial or high-traffic sites, combining regular inspections with occasional cleaning ensures that driveway chain fence or perimeter fences remain strong and secure. Even in environments with harsh weather, a well-maintained chain fence privacy system continues to provide reliable protection for pets, children, or valuable property.

Investing in high-quality chain wire fencing from experienced suppliers like SHENZHOU TIKE METAL CO., LTD ensures that buyers receive durable, ISO-certified fencing solutions capable of lasting decades. Unlike wood or vinyl fences, which may warp, crack, or require frequent replacement, a properly installed and maintained galvanized chain link fence or PVC-coated garden chain fence offers long-term security with minimal upkeep. This combination of durability, low maintenance, and cost-effectiveness makes chain wire fencing an excellent choice for B2B customers seeking reliable and enduring perimeter protection.

Isabella Rossi

Real Estate Manager, Italy

Thomas Müller

Factory Operations Manager, Germany

Lucy Evans

Residential Developer, Australia

John Baker

Commercial Property Manager, USA

Send a Message

WE ARE HERE TO ASSIST YOU EVERY STEP OF THE WAY.

We are committed to providing you with the best possible service andassistance. If you need any help or have any questions, please feel free toreach out to us. We are here to assist you every step of the way.