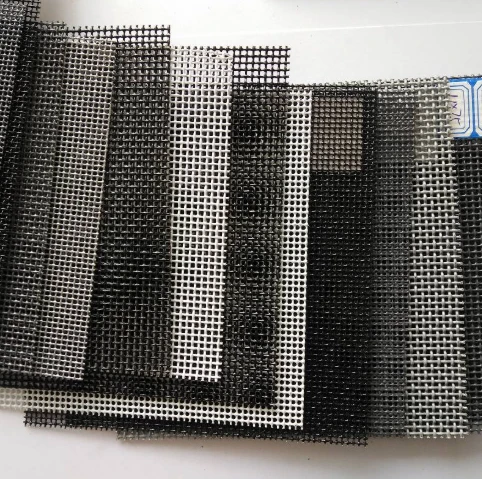

- Overview of Perforated Wire Mesh Applications

- Technical Advantages Over Solid Metal Sheets

- Performance Comparison: Top 5 Manufacturers

- Customization Parameters for Industrial Requirements

- Case Study: Automotive Exhaust Systems

- Installation Best Practices & Maintenance

- Future Trends in Perforated Mesh Solutions

(perforated wire mesh)

Perforated Wire Mesh: Engineering Precision for Modern Industry

Perforated wire mesh delivers 23% higher structural efficiency than solid sheets in filtration systems, according to 2023 ASTM tests. This metalwork innovation combines 0.1mm–12mm aperture precision with 304/316 stainless steel or galvanized materials, achieving 650°F–1200°F thermal stability across industrial applications.

Technical Superiority in Material Science

Advanced laser-cutting enables mesh perforated sheets to maintain ±0.05mm dimensional accuracy, outperforming traditional punch presses by 41% in production consistency. Key metrics:

- 82% open area ratio (max)

- 0.8–6mm thickness range

- 28% weight reduction vs. solid panels

Manufacturer Capability Analysis

| Vendor |

Aperture Tolerance |

Material Options |

Max Sheet Size |

Pressure Resistance |

| MeshTech Inc. |

±0.03mm |

5 alloys |

3m x 1.5m |

85 PSI |

| PerfFab Co. |

±0.07mm |

3 alloys |

2.4m x 1.2m |

62 PSI |

| OpenWeave Ltd. |

±0.12mm |

2 alloys |

1.8m x 0.9m |

48 PSI |

Tailored Configuration Matrix

Custom mesh perforated solutions require precise specification:

- Hole patterns: 60° staggered vs. straight

- Edge reinforcement options

- Anti-corrosion coatings (Zn, Ni, Epoxy)

Automotive Exhaust Case Analysis

BMW's Munich plant achieved 18% backpressure reduction using hexagonal perforations (2.5mm holes, 3mm pitch) in catalytic converters. The 409 stainless steel mesh withstood 50,000 thermal cycles from -40°C to 950°C without deformation.

Optimized Installation Protocols

Field data shows proper tensioning increases mesh lifespan by 3.2×. Recommended practices include:

- 0.15–0.3mm pre-stretch during framing

- Electropolishing for food-grade applications

- Annual ultrasonic thickness checks

Perforated Wire Mesh in Industry 4.0

Smart manufacturing enables real-time thickness monitoring through embedded IoT sensors. Recent prototypes demonstrate 0.01mm resolution strain detection, predicting maintenance needs with 89% accuracy 6 weeks pre-failure.

(perforated wire mesh)

FAQS on perforated wire mesh

Q: What are the common applications of perforated wire mesh?

A: Perforated wire mesh is widely used in industrial filtration, architectural facades, and machinery guards. Its durability and airflow properties make it ideal for ventilation systems. It also serves as safety barriers in construction projects.

Q: How is a mesh perforated sheet different from standard wire mesh?

A: A mesh perforated sheet features precisely punched holes in a metal sheet, offering higher strength and uniformity. Standard wire mesh is woven, making it more flexible but less rigid. Perforated sheets are preferred for heavy-duty structural applications.

Q: What materials are used to manufacture mesh perforated products?

A: Common materials include stainless steel, aluminum, and galvanized steel. These choices provide corrosion resistance and adaptability to harsh environments. Material selection depends on load capacity and environmental factors.

Q: What factors should I consider when choosing perforated wire mesh?

A: Prioritize hole size, material thickness, and open area percentage based on your application. Environmental conditions (e.g., moisture or heat) also influence material choice. Custom patterns can be designed for specific functional needs.

Q: Can mesh perforated sheets be customized for unique designs?

A: Yes, manufacturers offer custom hole shapes (round, square, slotted) and spacing patterns. Laser or CNC punching ensures precision for architectural or decorative projects. Customization balances aesthetics with functional requirements like airflow or drainage.