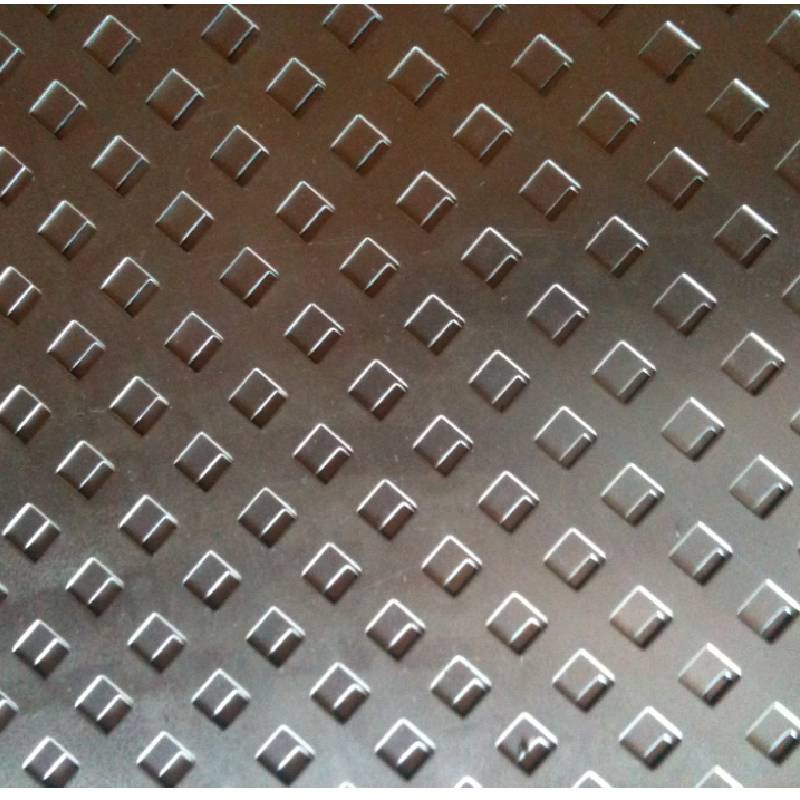

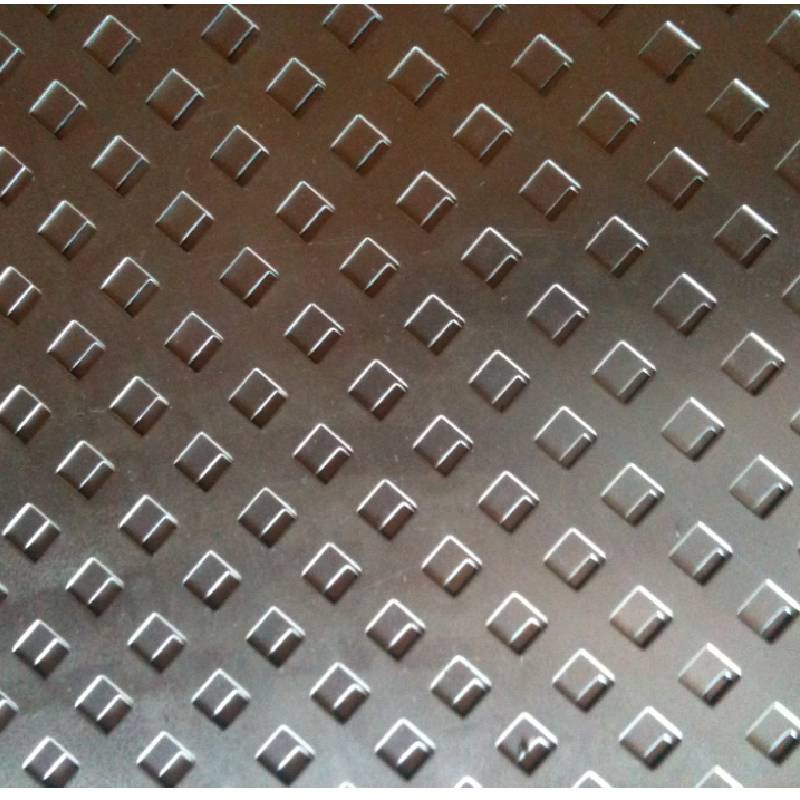

Galvanized GI wire, a staple in construction, manufacturing, and telecommunications, demonstrates an impressive blend of durability, versatility, and affordability. For industry experts seeking reliable materials, the significance of GI wire cannot be overstated. Its unique galvanization process ensures enhanced protection against corrosion, making it indispensable for both indoor and outdoor applications.

The process of manufacturing galvanized GI wire involves coating standard carbon steel wire with zinc. This zinc layer acts as a formidable barrier, safeguarding the underlying steel from environmental factors like moisture and chemicals. Professionals in sectors ranging from agriculture to construction appreciate the resilience and long-lasting nature of GI wire, which reduces maintenance costs and extends product life.

For construction experts,

galvanized GI wire is often employed in concrete reinforcement. Its strength and flexibility support structural integrity in buildings, bridges, and roads. Unlike other materials, the wire exhibits considerable tensile strength, maintaining its form under stress. The construction industry benefits from its ability to withstand heavy loads while adhering to safety standards, ensuring that infrastructure projects endure over time.

In the realm of telecommunications, GI wire serves as an essential component in the installation of fences and cables. Its resistance to temperature fluctuations and environmental exposure makes it ideal for use in varied climates. Professionals using GI wire in these applications emphasize its reliability in maintaining connectivity and safeguarding equipment, ensuring seamless communication infrastructure across regions.

Agricultural professionals also lean heavily on galvanized GI wire for fencing and protection of crops. The wire forms robust barriers that protect livestock and property while withstanding harsh weather conditions. As a cost-effective solution, it allows for extensive coverage without frequent replacement, supporting sustainable and efficient farming practices.

galvanized gi wire

The expertise required to select the right type of galvanized GI wire involves understanding its gauge, tensile strength, and coating mass. Experts recommend a thorough assessment of the specific application needs to determine the appropriate wire specifications. For instance, heavier coatings are advised for environments with higher corrosion risks, while the choice of gauge depends on the expected load-bearing requirements.

With an emphasis on trustworthiness and customer satisfaction, manufacturers and suppliers of galvanized GI wire often adhere to international standards, ensuring consistent quality. Industry professionals are advised to partner with reputable suppliers who provide certification and detailed product information, promoting confidence in its performance across applications.

Furthermore, the adoption of sustainable practices in the production of galvanized GI wire adds to its credentials. Many manufacturers now employ environmentally friendly processes, reducing the ecological footprint without compromising on quality. This aligns with the increasing demand for sustainable construction and manufacturing materials, reinforcing the authority of galvanized GI wire in the modern marketplace.

In summary, galvanized GI wire stands out as a highly reliable material across various industries due to its robust nature, cost efficiency, and adaptability. Professionals across construction, agriculture, and telecommunications have long recognized its value in supporting infrastructure and projects that demand resilience and longevity. As industry needs evolve, so too does the range of applications for galvanized GI wire, solidifying its reputation as an invaluable resource in material selection.