Steel diamond mesh sheets have revolutionized the way industries approach construction, manufacturing, and design. With a unique combination of strength, flexibility, and aesthetic appeal, these sheets cater to a wide array of applications. For those looking to delve into the multifaceted world of steel diamond mesh sheets, exploring user experiences, expert insights, and authoritative applications can provide a well-rounded understanding of their potential and reliability.

When discussing the experience of using steel diamond mesh sheets, one cannot overlook their adaptability across various projects. Numerous construction professionals highlight the ease with which these sheets can be cut, formed, and installed. Their lightweight nature compared to solid metal plates means that they are easier to handle, reducing labor costs and installation time. Construction of facades, fencing, and walkways frequently employs steel diamond mesh due to its ability to provide strength without unnecessary bulk.

Expertise in material sciences points to the structural integrity of steel diamond mesh sheets as a key factor for their widespread use. These sheets are manufactured through a precise process of cutting and stretching, which results in a robust, non-slip surface ideal for high-traffic areas. Engineers appreciate the high strength-to-weight ratio, which makes them suitable for load-bearing applications while maintaining portability. Furthermore, the open diamond pattern allows for excellent air and light flow, making it an increasingly popular choice for architectural projects that seek both form and function.

In terms of authority, steel diamond mesh sheets are recognized globally for their compliance with safety and quality standards, making them a trusted choice in safety-critical applications. The oil and gas industry, for instance, often incorporates these sheets in platform grating and stair treads. Their ability to withstand harsh environments without corroding ensures long-term durability. Additionally, many manufacturers offer galvanizing or powder coating options, extending the lifespan of the material even further in tough weather conditions.

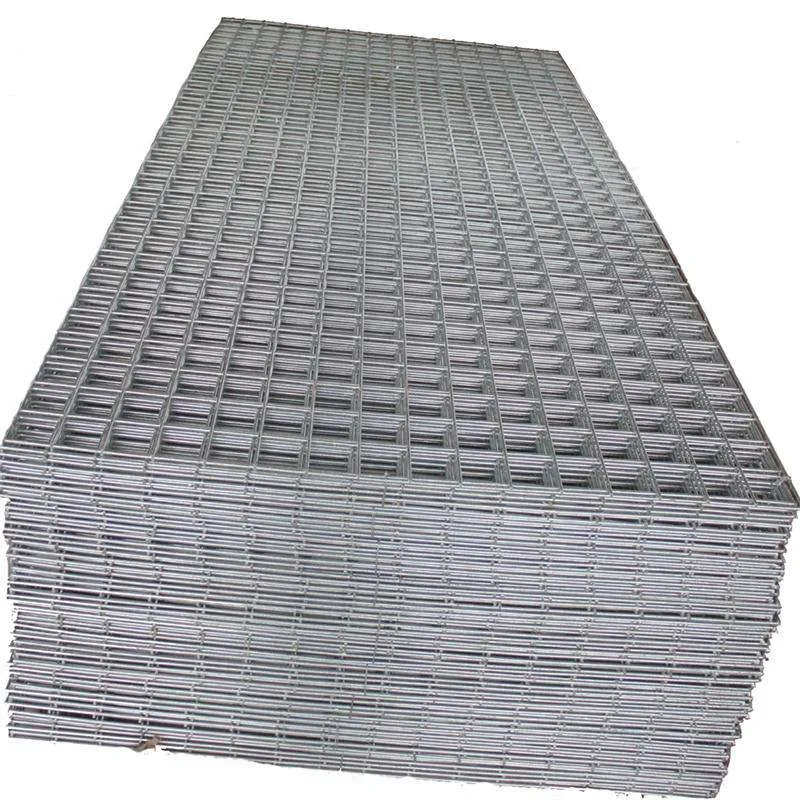

steel diamond mesh sheets

For those concerned with trustworthiness, steel diamond mesh sheets stand as a testament to reliability and quality. Feedback from industries ranging from transportation to architectural design consistently reflects a high level of satisfaction. End users praise their resistance to wear and tear, even in demanding environments such as factories and outdoor settings. Moreover, their recyclability aligns with sustainable practices, providing an eco-friendly solution for those mindful of environmental impact.

The versatility of steel diamond mesh sheets is further highlighted by their role in innovative design projects. Architects and designers utilize these sheets not only for their functional benefits but also for their aesthetic potential. The ability to customize patterns and finishes allows for unique visual effects, catering to modern architectural trends that prioritize both beauty and practicality. Public spaces benefit from these features, where installations can double as art pieces without compromising their intended purpose.

In terms of customization, steel diamond mesh sheets offer endless possibilities. They can be tailored to specific project needs, whether it's the thickness of the material, the size of the diamonds, or the type of finish. This adaptability makes them suitable for bespoke projects where unique design specifications are required. These custom solutions ensure that the end application is not only fit for purpose but also tailored to the unique requirements of the client or project at hand.

Overall, steel diamond mesh sheets exemplify a blend of innovative engineering and practical application. Their acceptance and use across diverse industries underscore their effectiveness and efficiency. As they continue to adapt to modern needs through advancements in technology and design, steel diamond mesh sheets remain integral to a myriad of applications—offering unparalleled performance and enhancing the environments they are part of. With a strong foundation built on experience, expertise, authority, and trustworthiness, these utility-driven materials are poised to meet the future demands of industries worldwide.